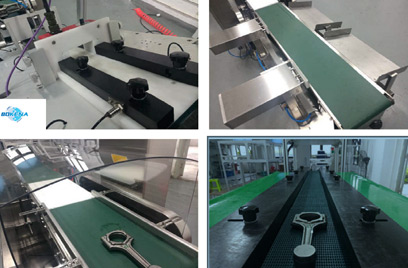

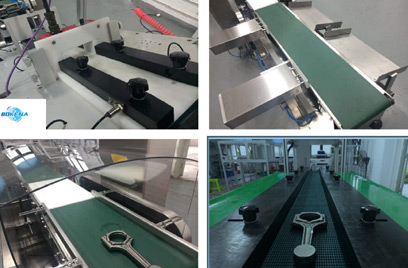

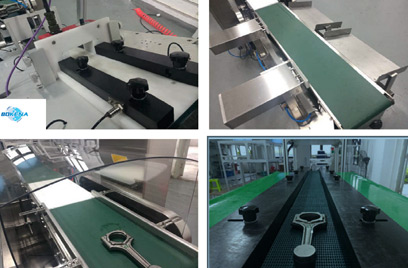

Eddy Current Testing Equipment

An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady current field generated by a capacitor or an intermittent source. The alternating current we use can be regarded as a pulse current, and one of the cycle processes can be regarded as an electrical pulse. Modern electric pulse technology has developed to the trend of higher frequency and high energy peaks. It has a wide range of applications in materials testing, biology, medicine, nuclear energy, military and other fields. The main working principles are high energy Joule heating effect, hot pressing effect, high-frequency magnetic induction effect, electroforming and so on. Common waveforms are a rectangular, sinusoidal, rectangular, sinusoidal, group, and so on.

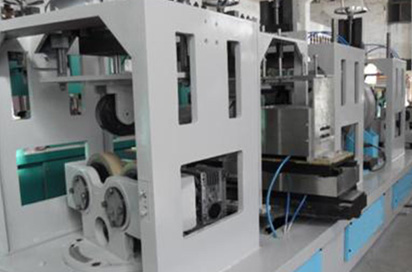

The EDM notch machineis mainly used for the production of standard sample tubes in the non-destructive testing industry, and is an indispensable auxiliary device for nondestructive testing. It can be used to make internal and external longitudinal defects on the sample tube, internal and external lateral defects, and can also make oblique defects at a certain angle according to different requirements of users, and can also make thickness measurement standard sample tubes or layered standard sample tubes. The shape has a U-shaped groove, a rectangular or square groove, a flat bottom hole, and the like. The machining precision is high, the speed is fast, the operation is simple, the degree of automation is high, and the machining depth can be set in one time, and the error is within the allowable tolerance range. The device is light and easy to carry, and can be used in different field environments.

The main features of the EDM notching services:

Small size, light weight and easy to carry

High power, fast scratching, less than 10% error

The distance between the internal injury position and the tube end is not limited, and the position of the wound is accurate

Single-chip control, simple operation, intelligent and efficient, practical

It is only necessary to clean the circulating oil normally, and it is basically maintenance-free

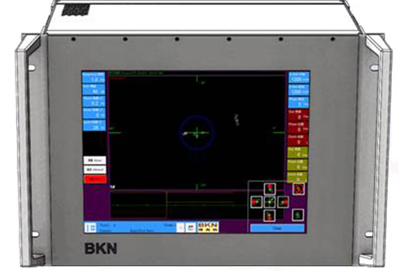

Nanjing BOKENA Automation System Co., Ltd., originated from the eddy current testing laboratory of the Nanjing University of Technology. It isone of the most professional ndt testing equipment suppliersin China. We sincerely invite and welcome people from all around the world to invest and create more values together.

在线联系供应商

Other supplier products

| Eddy Current Testing Equipment | Are you looking for eddy current equipment for sale? ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagneti... | |

| Benchtop Magnetic Flux Leakage Testing Equipment | MFI Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to def... | |

| Eddy Current Testing Equipment | ECT Eddy current testingis a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals ... | |

| Steel Bar Testing | The steel bar is rolled by a rolling mill and produce both surface defects and internal defects during the rolling process. The internal defect is ... | |

| Valve Tappet Eddy Current Flaw Detector QMTZET-04 | Tappet full automatic eddy current testingsystem is a full automatic crack hardness sorter that integrates light, electricity and machinery. The wh... |

Same products

| Tandem roller bearing M4CT3278 with shaft 78x32x110.5mm | 卖方: JinHang Precision Bearing Co.,LTD | The tandem roller extruder bearing m4ct3278 that use for PVC screw extruder gearbox, the shaft di... | |

| Tandem roller bearing F-86722 for Rubber extrusion machine | 卖方: JinHang Precision Bearing Co.,LTD | The bearing f-51909 t3ar mainly used in the twin screw plastic extrusion machine gearbox.The bear... | |

| Tandem roller bearing t6ar3278 for the extruder shaft gearbox | 卖方: JinHang Precision Bearing Co.,LTD | The bearing T6 AR 3278 with size 32X78X163.5mm mainly used for the high speed extruder machine ge... | |

| Tandem roller bearing MTCT2468 for Screw extrude gearbox | 卖方: JinHang Precision Bearing Co.,LTD | The bearing M5CT2468 for food/feed/plastic/rubber extrusion machine gearbox use. With high perfor... | |

| twin screw extruder gearbox used t5ar3278 bearing | 卖方: JinHang Precision Bearing Co.,LTD | Bearing T5AR3278 fullsize 32x78x137mm bearing actual picture, Please reference them. Bearing fact... |