Wireless Transmission Steel Bar Ultrasonic Flaw Detector

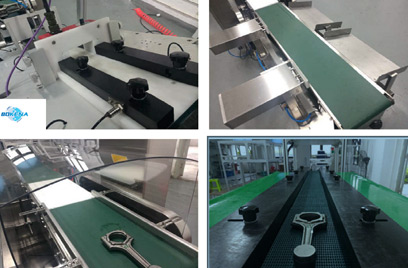

Steel bar is a conventional product with high density, moderate noise. The system is suitable for the automatic detection of internal and external defects of various steel bars.

The principle of UT ultrasonic flaw detection is that after the ultrasonic wave is coupled into the steel rod by water, the incident propagation will case ultrasonic reflection when there is a defect in the bar. The ultrasonic instrument will alarm the ultrasonic reflected signal after the amplified signal to realize the automatic detection of the defect.

Wireless Transmission Steel Bar Ultrasonic Flaw Detector Brief Introduction

There are two probe regulators in section 1,180 degrees apart. Each regulator is equipped with a two-channel combination of ultrasonic line focus probes, and the transverse wave incident clockwise.

Detection of defects: detection of round subcutaneous defects in a rounded clockwise direction

Center frequency: 5.0MHz ± 10%

Coupling method: water immersion method

Quantity: 2 sets of probes, each set consisting of 2 combined wafers, which are evenly distributed in the circumferential direction of the workpiece, 180° apart, on the same section. A total of 4 independent channels.

A total of 2 probe adjustment frames are placed on section 2, each separated by 180°, and a 2-channel combined ultrasonic line focusing probe is arranged on each adjustment frame, and the longitudinal wave is incident.

Detection of defects: metallurgical defects inside the steel bar,

Detection range: center transverse hole.

Center frequency: 5.0MHz ± 10%

Coupling method: water immersion method

Quantity: 2 sets of probes, each consisting of 2 combined wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, 180° apart, and there are 4 independent channels in the same section.

A total of 2 probe adjustment frames are placed on section 3, each separated by 180°, and a 2-channel combined ultrasonic line focusing probe is arranged on each adjustment frame, and the transverse wave is incident counterclockwise.

Detection of defects: counter-clockwise detection of round subcutaneous defects

Center frequency: 5.0MHz ± 10%

Coupling method: water immersion method

Quantity: 2 sets of probes, each consisting of 2 combined wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, 180° apart, and there are 4 independent channels in the same section.

Defect detection standard

GB/T4162-2008 Ultrasonic testing method for forged steel bar.

Wireless Transmission Steel Bar Ultrasonic Flaw Detector Parameters

|

Channel number |

12 channels |

|

Flaw detection speed |

30m/min |

|

Total gain |

100dB,step0.5dB |

|

Working mode |

Single probe transmitting, receiving or double probe transmitting and receiving respectively |

|

Sensitivity margin |

≥50dB |

|

Resolving power |

≥26dB |

|

Dynamic range |

≥30dB |

|

scan range |

0~5000mm |

|

Frequency range |

|

|

Sampling range |

250MHz |

|

Repetition range |

Single channel100Hz~4KHzadjustment |

|

Vertical linearity |

≤2% |

|

Horizontal linearity |

≤1% |

|

Detection mode |

Full-wave, positive half-wave, negative half-wave |

|

Gate setting |

Each channel has three gates, A and B are defective gates and C are interface tracking gates. |

|

Alarm indication |

Color Display and Sound Alarm of A, B and C Gate Alarm on Each Channel |

|

Delayed alarm |

Two path,delay time 0.1-10s,step 0.1s |

|

Waveform storage, unlimited number, waveform playback, printing and report generation. |

|

BKNis a professionalmfl suppliers. We provide Eddy Current Testing, Magnetic Flux Leakage Testing, ndt device, ndt testing, ultrasonic metal testing equipment, ultrasonic bar testing, ultrasonic metal testingand so on. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| LGET-553 Aluminum Tube Eddy Current Flaw Detector | LGET-553 Aluminum Tube Eddy Current Flaw Detector Brief Introduction The aluminum tube is a type of non-ferrous metal which may have one or more... | |

| Eddy Current Testing Equipment | An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady ... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | The technology of BKN originated from eddy current Laboratory of Institute of Materials, Nanjing University of Technology. At present, it is a lead... | |

| Magnetic Flux Leakage Testing Equipment | Electromagnetic detection is a very important non-destructive testing method and is widely used. Mag flux testingis a magnetic method of nondestruc... | |

| Valve Tappet Eddy Current Flaw Detector QMTZET-04 | Tappet full automatic eddy current testing system is a full automatic crack hardness sorter that integrates light, electricity and machinery. The w... |

Same products

| DM-16BF DM-18BF New cover Electric Sprayer | 卖方: Zhejiang Huaqi Information Technology Co., LTD | The Electric Knapsack Sprayer is a game-changer in the field of agricultural pest control. Engine... | |

| Simple Round Breeding Cage | 卖方: Zhejiang Huaqi Information Technology Co., LTD | The Simple Round Breeding Cage features a durable and lightweight construction, making it suitabl... | |

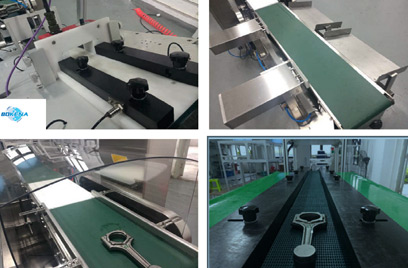

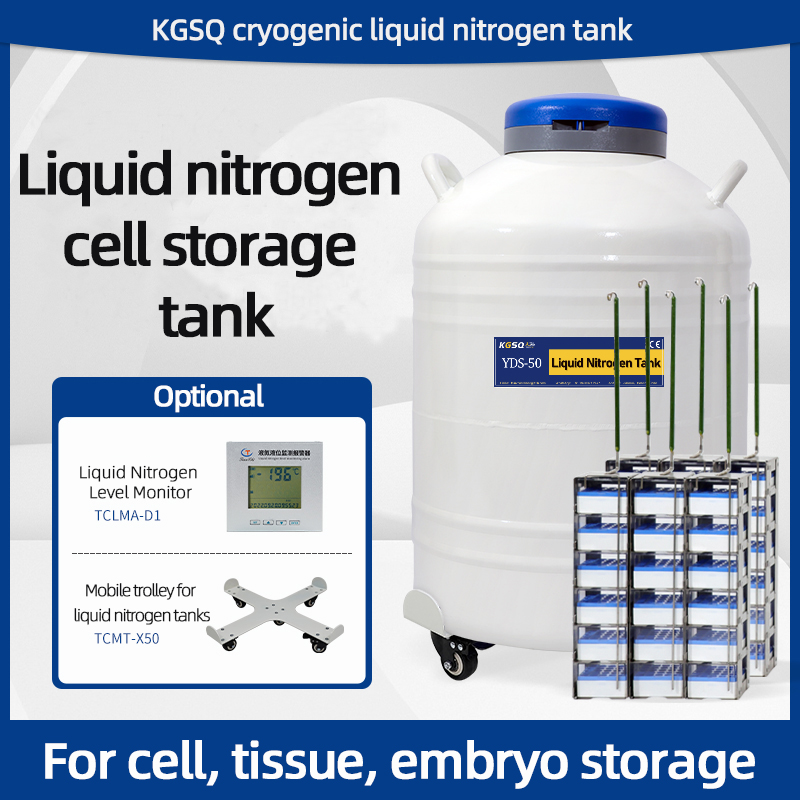

| 叙利亚-细胞储存液氮容器-液氮液位报警器 | 卖方: 河南天之道生物科技有限公司 | 精准的实验条件与安全的样本存储是科研工作顺利开展的关键要素。其中,细胞储存液氮罐作为实验室不可缺少的一种设备,在样本保存方面发挥着重要的作用。 实验室用的细胞储存液氮罐,航空铝制造,重量轻、占用... | |

| 意大利-液氮细胞储存罐-液氮罐液位报警器 | 卖方: 河南天驰仪器设备有限公司 | 精准的实验条件与安全的样本存储是科研工作顺利开展的关键要素。其中,细胞储存液氮罐作为实验室不可缺少的一种设备,在样本保存方面发挥着重要的作用。 实验室用的细胞储存液氮罐,航空铝制造,重量轻、占用... | |

| 埃及-细胞储存液氮罐-液氮液位监测仪 | 卖方: Henan Tianzhidao Biological Technology Co., Ltd. | 精准的实验条件与安全的样本存储是科研工作顺利开展的关键要素。其中,细胞储存液氮罐作为实验室不可缺少的一种设备,在样本保存方面发挥着重要的作用。 实验室用的细胞储存液氮罐,航空铝制造,重量轻、占用... |