Eddy Current Testing Equipment

Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing tubing. It can ensure the quality of oil and water wells to prolong the inspection cycle, reduce the rework of operations and reduce operating costs.

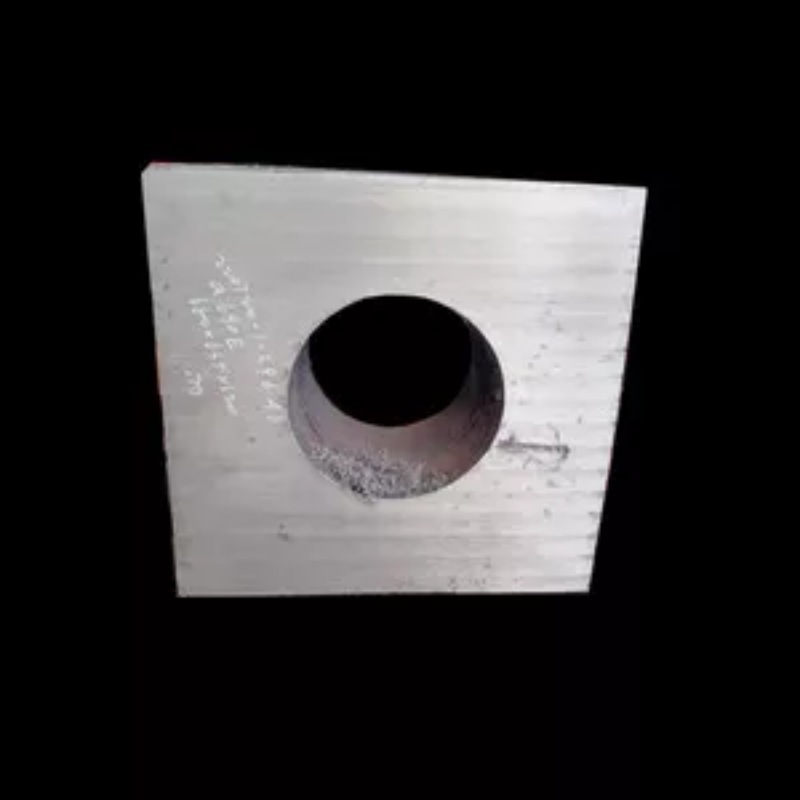

As an important process in the tubing repair test line, the flaw detection can accurately and effectively detect the defects in the manufacture and use of the inner and outer wall and the pipe body of the oil pipe to ensure the repair quality of the oil pipe.

Fundamental

When the detected tubing is saturated and magnetized, the magnetic field lines are distorted by the magnetic lines of force at the defect blocking defect, and a part of the magnetic lines leak out of the inner surface of the tube rod to form a leakage magnetic field, and the electromagnetic detecting method for detecting the leakage magnetic field by the detecting element is detected. Magnetic flux leakage inspection.

The mfl tubepicked up by the probe from the defect is amplified and converted into a digital signal, and then visually reflected by the flaw detector to the display to display the defect signal from the flaw detector, and directly determine the defect type and size of the detected tube rod.

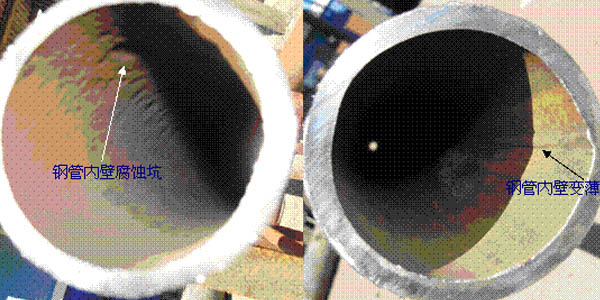

¢73 and ¢89mm tubing eccentric wear and corrosion pits are detected, automatic detection, automatic alarm, automatic identification, automatic alarm.

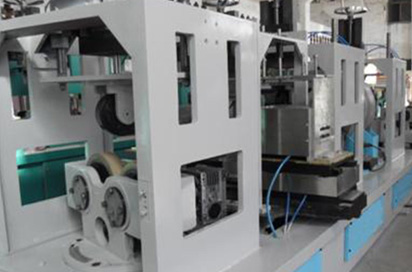

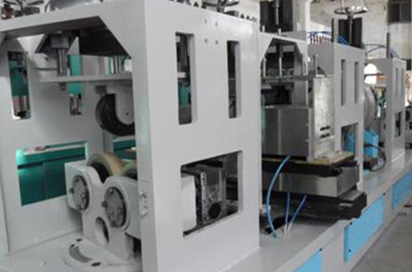

Our company's new MFI mfl tube inspectionmachine has high sensitivity to very small defects. It can effectively detect defects such as corrosion pits, eccentric wear on the inner wall of the tubing, thinning of tubing wall, etc.

Moreover, the testing speed is fast and pollution-free, and the detection is fully automated. The computer display screen is used to display the detection curve, automatic alarm, marking (defect of steel pipe), grading of tubing (grade I, II and scrap).

Nanjing BOKENA Automation System Co., Ltd., originated from the eddy current testing laboratory of the Nanjing University of Technology. It isone of the most professional ndt testing equipment suppliersin China. We sincerely invite and welcome people from all around the world to invest and create more values together.

在线联系供应商

Other supplier products

| GTET-02 Cylinder Liner Eddy Current Testing Machine | We have eddy current machine for sale! GTET-02 Cylinder Liner Eddy Current Testing Machine Introduction The rate of missed standard defect is 0... | |

| MFL-7389 Tube Magnetic Flux Leakage Detector | Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing t... | |

| Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02 | During the processing of bearing rings, various defects are often generated on the surface or inside, and cracks occupy a large proportion of all d... | |

| Eddy Current Testing Equipment | Automatic EDM notch machineis the ideal equipment for processing artificial defects of pipe rod standards in non-destructive testing work. The flaw... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. A... |

Same products

| Drum Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Drum Forging Drum Forging Brand origin: Runchi shandong Processing ability: turning, milling, pla... | |

| Wheel Hub Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Wheel Hub Forging Wheel Hub Forging Main features: [Manufacturing Standards] Strictly produce for... | |

| Nozzle Forging Nozzle | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Nozzle Forging Nozzle Forging Brand origin: Runchi shandong Processing ability: turning, milling,... | |

| Marine Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Marine Forging Marine ForgingMain features: [Manufacturing Standards] Strictly produce custom f... | |

| Bearing Housing | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Bearing Housing Product Name: Bearing housingBrand origin: Runchi shandong Processing ability: ... |