ECT For Automotive And Aerosapce

Eddy current testing technology has been widely used in the detection of metal components in the automotive and aerospace industry. In order to ensure the flight safety of the aircraft, the relevant components must be periodically inspected. The eddy current technology is usually used to detect aero-engine blade cracks, bolts, cracks in the screw holes, multi-layer structure of the aircraft, landing gear, wheels and aluminum skin as the aircraft non destructive testing. And subsurface defects, and used to detect defects in the wing joint weld. In the detection, it can effectively suppress the shaking of the probe, and the material is uneven and cause interference signals. Metal magnetic memory testing technology can be used to diagnose the stress concentration of the above components or early damage.

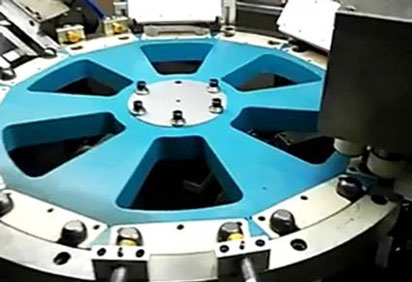

Due to the complex geometry of the auto parts, the equipment is required to have a high level of materials and complicated materials, requiring diverse equipment and high precision. In addition, the production of auto parts is a large industrial production, with certain beat monitoring requirements, and only by reducing the testing costs, can we reduce the automobile production and improve the competitiveness in the domestic and foreign markets. With the development of the national economy, the automobile industry has become a pillar industry in China. Therefore, non-destructive testing technology for eddy current flaw detectors for automotive parts is also receiving increasing attention from manufacturers and researchers. At present, the most widely used non destructive testing machine in the detection of automotive parts is the eddy current flaw detector ultrasonic testing method. In the ultrasonic flaw detection of eddy current flaw detectors at home and abroad, the most used type A ultrasonic flaw detector. It adopts A-type ultrasonic display, which has the advantages of simple and cheap equipment, can locate and quantify defects, and is widely used in production inspection.

However, its flaw detection results are not intuitive, no record, difficult to detect, and many human factors. Seriously affect the reliability of detection. Due to the continuous development of computer technology and electronic devices, the digital acquisition and analysis of the ultrasonic signal of the eddy current flaw detector become possible, the waveform can be recorded and preserved, and the ultrasonic detection of the eddy current flaw detector is positive digital signal processing and imaging direction development. Super-generation image technology is a remarkable new technology. The ultrasonic image of the object can provide intuitively and a large amount of information, directly reflecting the acoustic and mechanical properties of the object, and can also evaluate the mechanical properties of the microstructure of the solid material. Suddenly macroscopic discontinuities. In short, the aviation ndt services for automotive parts eddy current flaw detector will develop with the advancement of modern high-tech, to the direction of intelligence, automation and imaging, in order to adapt to the rapid development of modern automobile manufacturing industrial parts quality inspection, testing requirements.

在线联系供应商

Other supplier products

| QTXET-01 Ball Studs Eddy Current Sorting Machine | There are two main types of ball studs: one is a combination of a spherical pin and an integral ball seat, and the other is a combination of a hemi... | |

| Magnetic Flux Leakage Testing Equipment | Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage is a magnetic method of nond... | |

| Eddy Current Testing Equipment | An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady ... | |

| Benchtop Magnetic Flux Leakage Testing Equipment | Benchtop magnetic testing equipment MFI Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test pi... | |

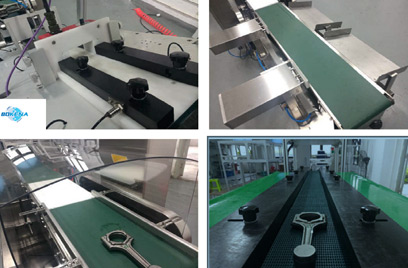

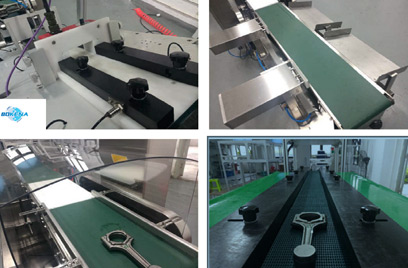

| Connecting rod hardness eddy current sorting machine LGYDFX-01 | The connecting rod hardness eddy current sorting machinehas a calibration device, input compensation parameters, automatic/manual temperature compe... |

Same products

| Electric Motorcycle High Energy Lithium Battery | 卖方: Taizhou CGONEN New Energy Co., Ltd. | Our 60V26Ah/ 60V29Ah/ 60V32Ah NMC high-speed electric motorcycle high-energy lithium batteries re... | |

| JCID V15系列 iPhone Android 屏幕测试仪 | 卖方: 深圳维客修有限公司 | 描述JCID V15/V15PM屏幕测试仪支持测试iPhone屏幕和Android Phone屏幕的全部功能,如iPhone LCD屏幕触摸功能测试、单色测试、图片测试和灰度测试。全新JCID ... | |

| Self Leveling Laser Level | 卖方: Holo Precision Instrument Co.,ltd. | When choosing a self-leveling laser level, several features should be considered : Accuracy L... | |

| Nivel De Laser | 卖方: Holo Precision Instrument Co.,ltd. | A great nivel de laser boasts essential features like high accuracy (measured in millimeter... | |

| Floor Laser Level | 卖方: Holo Precision Instrument Co.,ltd. | In the realm of precision tools, a ceiling laser level stands out as an indispensable asset for... |