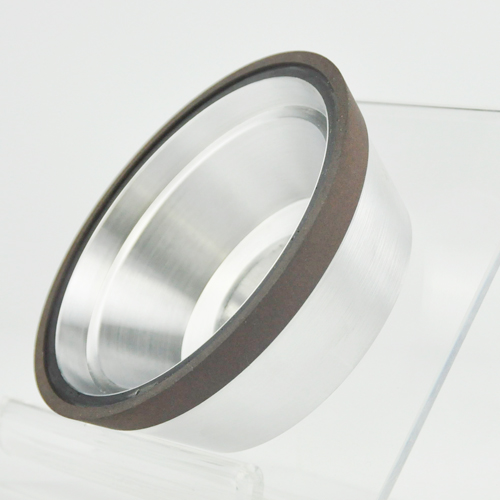

cnc grinding wheel

JR diamond toolsis an experienced manufacturer of High QualityDiamond and CBN grinding wheels.JR diamond tools companysupplies the wheels for several applications:

Carbide Round tools on CNC machines:Flute Grinding,Gash Grinding,end facing, Clearance angleCylindrical grinding.

Insert grinding for machines such as: AGATHON, WENDT, HAAS, WAIDAand EWAG.

Woodworking saws and tools.

HSS tools.

Cut off wheels.

STORAGE

Diamond and CBN grinding wheels should be carefully stored in original packaging and the core should be kept oiled.

MACHINES

Machines should be in good working condition, well maintained and free of vibration. Special attention should be given to the spindle which should run true and the spindle bearings which should be in good condition.

WHEEL MOUNTING

After cleaning and checking the mounting arbor and flange, the wheel should be running true to within 0.02 mm.

COOLANT

• Synthetic oil – Most popular• Emulsion (water based)Water with an added rust inhibitor is sufficient for diamond grinding wheels. The life of CBN grinding tools can be significantly extended by using pure oil yet an emulsion with oil concentration should be sufficient.

CUTTING FLUIDS

Cutting fluids should be used whenever possible when using diamond wheels, to reduce the heat generated by grinding as well as to extend the wheel’s life. If it’s necessary to dry grind, a corret resin-bond wheel should be used.

COOLANT FLOW

The best cooling effect is achieved when the outlet speed of the cooling lubricant is adapted to the peripheral speed of the grinding wheel, and the nozzle opening is only slightly wider than the grinding rim.A small trickle of coolant occasionally applied, is better than no coolant at all. This causes alternate heating and quenching, which can cause damage to the diamond wheel and carbide tools.

FLUTE GRINDING

Grinding wheels used: 1A1, 1V1, 14A1, 14V1, 3A1, 3V1As flute grinding accounts for the majority of grinding time it is essentialto optimise the machine, cooling systems and grinding wheels. POMDIhas developed a new hybrid bonding agent that removes high volumesat material at high operating speeds whilst minimising grinding wheelwear. This bonding agent also lowers energy consumption.

RELIEF AND GASH GRINDING

Grinding wheels used: 12V9, 1V1, 14V1This process also sometimes needs to remove a lot of material.Consequently, the objective is to maximise cutting capacity whilstminimising grinding wheel wear.

CLEARANCE ANGLE AND OUTER DIAMETER

Grinding wheels used: 11V9, 6A9, 6V5, 11A2, 12A2, 11V5,12V5, 12V2Clearance angles are used on the face and around the lip to reducethe contact surface between the tool and the workpiece during drillingor milling.

在线联系供应商

Other supplier products

| 12A1 vitrified bond diamond and CBN grinding wheel | Introduction: Vitrified bond diamond grinding wheels possess pretty high abrasive resistance,especially in polishing hard and brittle work-piece. ... | |

| Electroplated Diamond / CBN Grinding Wheel | Electroplated grinding wheels with nickel bonding can achieve high stock removal rates and high-precision profiles on parts being ground. Depending... | |

| Saucer type grinding wheel | 12V9 diamond grinding wheel used for sharpening and finishing of cutting tools back surface. *The abrasive layer of the grinding wheel can be made... | |

| cnc grinding wheel | JR diamond toolsis an experienced manufacturer of High QualityDiamond and CBN grinding wheels.JR diamond tools companysupplies the wheels for sever... | |

| cup type diamond and CBN grinding wheel | Diamond grinding cup wheels are highly popular in the home improvement and construction industry. These are highly efficient in polishing, grinding... |

Same products

| HM Pumex Grinding Machine | 卖方: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| XZZ Z1 Pro 电动研磨笔 IC 抛光工具 | 卖方: 深圳维客修科技有限公司 | XZZ Z1 Pro 电动抛光笔,配备多种磨头,满足不同类型的手机主板 CPU IC 研磨和维修需求。2025 XINZHIZAO XZZ USB 充电式抛光研磨笔,适用于手机维修。 XZZ ... | |

| Scraper Grinding Machine | 卖方: Kunshan Dekaisheng Edge Mold Co.,Ltd | Usage: Our commpany develops and produces fully automatic and speed adjustable blade grinder with... | |

| IC抛光用小型电动研磨笔 | 卖方: PHONEFIX technology Co.,Ltd | 描述E288-02小型手持研磨机迷你主板CPU IC抛光笔雕刻工具。电动研磨笔适用于手机维修,IC CPU抛光,玉石玛瑙,核雕,木雕,研磨铝板,印刷电路板和环氧板以及手机液晶屏残留OCA胶去除。... | |

| 250mm 10 Inch Diamond Grinding Plates For Concrete | 卖方: Xiamen ChinShine Industry and Trade Corporation | ChinShine designed this new style China diamond grinding shoe was perfect for grinding concrete, ... |