5. Multi Cavity Mould

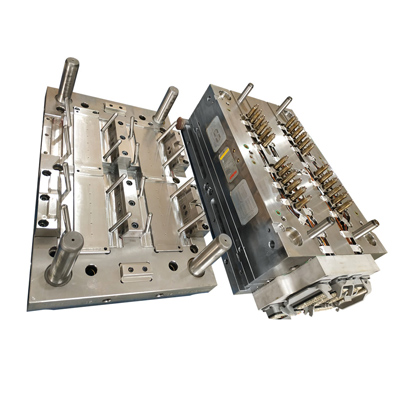

24 Cavities Plastic Injection Mold

Product Name: 24 Cavities Plastic Injection MoldMold Base: LKM, HASCO, DME, etc.Mold Steel: NAK80, ASSAB8407, S136, 718H, 738H, etc. Tolerance: +/-0.002mmFinish: Polish, Silk Screen, Painting, etc.

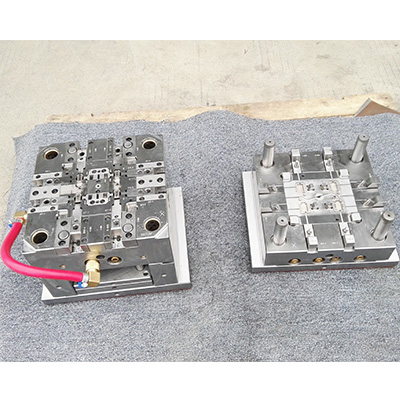

48 cavities mould

Mould Name: 48 Cavities MouldPart Material: PP AV161Product Size: 173.30*34.80*22.87MMProduct Description: C8 RI IBM FORKMould Cavity: 48 CavitiesMould Size: 1000*1400*900 MMSuitable Injection Machine...

8 Cavities Injection Mold

8 Cavities Plastic Injection Mold to produce plastic ear tag,High volume production mould.Mould Name: Animal Tag MouldPart Material:PPSProduct Size: φ15.6Product Description: Animal Plastic TagMould Cavity: 8+8 ...

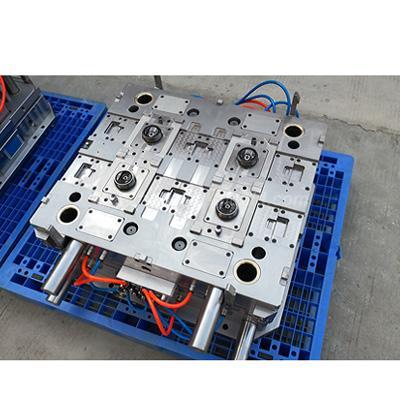

16 Cavities Mould

16 Cavities Plastic Injection Mold, very high precision plastic mould, important to control the dimension of each cavity insert, the insert is interchangeable.

8 cavity mold

8 Cavities Plastic Injection Mold to produce plastic ear tag, high volume production mould.Mould Name: Animal Tag MouldPart Material:PPS Product Size: φ15.6Product Description: Animal Plastic TagMould Cavity...

8 Cavities Mould

8 Cavities Plastic Injection Mold to produce plastic ear tag,High volume production mould.Mould Name: Animal Tag MouldPart Material:PPS Product Size: φ15.6Product Description: Animal Plastic TagMould Cavity: 8+8...

4 Cavities Mould

Plastic Injection Mould standard: DME, HASCO, Meusburger, China LKM Standard etc.Plastic Injection Mold Steel: ASSAB8407/P20/738/2083/2343ESR/NAK80/S136 etc. Mould Base: LKM Mould Base or others.

A multi cavity mouldcan be understood, obviously referring to mold with multiple cavities. The multi-cavity mold comprises a multi-cavity of the same plastic part and a multi-cavity of different plastic parts. The use of multi-cavity molds for injection molding of plastic products can increase production efficiency and reduce costs, so the multi-cavity moulds are becoming more popular.

Since the multi cavity injection moldingmust have multiple runners to supply the melt to each cavity, the rationality of the injection molding system design directly affects the quality of the injection molded parts, material consumption, production efficiency and economic benefits.

In order to ensure the uniformity and performance of the quality and performance of each cavity, the flow balance of the gating system during the injection process is very critical, so that the plastic melt can be filled the cavity with the same pressure and temperature at the same time. Therefore, filling balance is the most important factor to consider when designing a multi-cavity mould.

The arrangement of the cavity and the runner is divided into two categories: balanced and unbalanced.

The feature of balance type is the length, shape and section dimension of the runner from the sprue to each cavity are correspondingly the same, it can realize even feeding of all cavities and fill the cavity at the same time. However, the unbalanced feature is that the lengths of the runners from the sprue to the cavity gates are not equal, which is not conducive to balanced feeding, but the unbalanced arrangement can significantly shorten the overall flow of the melt in the gating system. The compact mechanism reduces heat loss and injection pressure loss during flow and shortens the mold filling time.

As a mold company China, hanking mouldingwill make a high quality service to you.

在线联系供应商

Other supplier products

| Automotive Mold | Hanking mouldingserves global Automotive & Vehicle products customers, more than 10 years of experience enabling the HanKing team to provide cu... | |

| Insert Molding | What is insert molding? Insert molding refers to a molding process in which an integrated product is made by inserting a pre-prepared metal materi... | |

| Over-Molding Parts | Overmolded Parts Shaping Mode: Plastic Injection MoldingProduct Material: 2344, H136, etc.Mold type: Plastic injection overmoldCavity number: singl... | |

| Unscrewing Cap Mould 0440 | 2k MouldName: Unscrewing Cap Mould Part Material: PP+TPE Product Size: Product Description: Mould Cavity: Mould Size: 750*810*700mm Suitable... | |

| Precision Mould | How to build a plastic precision hanking mould? HanKing Mould Enginering Ltd.hasbeen manufacturing plastic precision moulds for more than ten year... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |