Home Appliance Mould

We are one of theresponsible china injection molding suppliersand have experience in supplying custom plastic injection molding service for many years. Our production sites have been accredited the certification of TS16949, ISO 14001 and ISO 9001, etc. You can fully trust our production sites, products and place your orders.

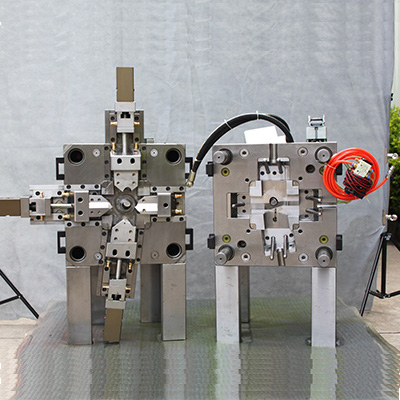

Embroidery Machine Frame Mould

Plastic frame for a multi-needle embroidery machine.Mould Name: Embroidery Machine Frame MouldPart Material: Pa 66 GF50%Product Size: Product Description Large Embroidery hoop frameMould Cavity: 1 CavityMould Size...

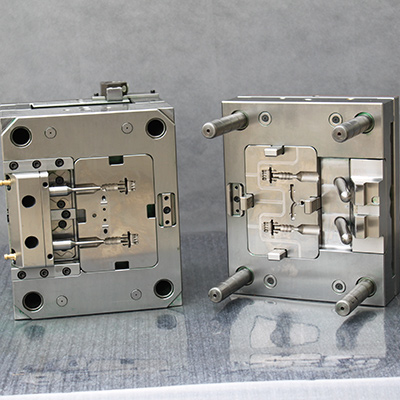

Sewing Machine Frame Mould

Large Plastic Frame Mould, suited for oversize embroidery projects.Mould Name: Embroidery Machine Frame MouldPart Material: Pa 66 GF50%Product Size: Product Description Large Embroidery hoop inner frameMould Cavity...

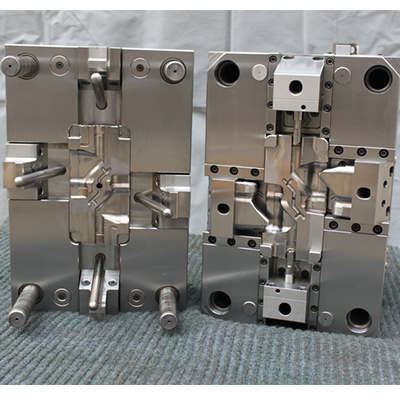

Coffee Machine Spare Part Mould

Home Appliance Mouldfor coffee machine, HanKing Mouldhave experience in different type Coffee Machine spare part moulds, some large part as housing, and small part is the tiny plastic filter.Mould...

Coffee Machine Piston Mould

Plastic piston for world famous Coffee Machine company, HanKing can build all size of plastic injection mould for home appliance and household industry, no matter single or multi cavity mould, simple...

Plastic Funnel Mould

Mould Name: Plastic Injection Wall Plug Mold Part Material: PBT GF15 Product Size: Product Description: Plug CH versionMould Cavity: 4 CavitiesMould Size: 392*300*335 MMSuitable Injection Machine:Mould Cavity...

Home appliance moldis also known as household appliance mould which is used to produce plastic parts and components for the household electric appliance.

The household appliance moulds generally include interior plastic parts moldand the exterior plastic housing or case.

For interior parts, dimensional accuracy is the most important, and there is usually no special requirement for appearance, as long as it does not affect the assembly of the products.

For exterior plastic housing or cases, the appearance and size are both important, but the exception is that some housing or cases will go to secondary processing, such as painting, plating etc., so that the injection-moulded exterior housing usually is not required to be high polish, only in some specific areas that affect the subsequent process are high polished.

How to ensure the accuracy of the plastic parts? First of all, to ensure the accuracy of the mould steel dimension. In HanKing, all the dimensions in the molds are within tolerance measured by CMM Zaiss before the moulds are delivered to our customers. We have good designers with more than 15 years of experience, providing good solutions and professional technical support. When we are designing a house appliance plastic injection mold, we should choose the mould steel by combining the total life cycles and the plastic resin of the part. Make inserts as much as possible for important dimensions or special structure area and some fragile ribs, because the inserts can be replaced and convenient maintenance after a long period of production. And machining by grinder as much as possible, in terms of accuracy, the grinding machine has its' advantage.

Every kind of machine has different advantages, toolmakers should understand the advantages of these devices and make the best use of them to help to make good quality moulds. Another point, keep some clearance for the mould steel is also very critical to get correct dimension parts.

Of course, it is far more than these points to make good quality moulds, please contact us and tell us your needs, we look forward to providing our professional support for your project.

在线联系供应商

Other supplier products

| Automotive Molding Parts | Car plastic mold mexico HanKing is specialized in high precision plasitc injectionmoulds and molding service of automotive parts for morethan 10 ye... | |

| Insert Molding | What is insert hanking moulding? Insert molding solutionsof hanking refers to a hanking mould technologyprocess in which an integrated product is m... | |

| Plastic Closure Mould mrm0441 | HanKing Mouldis an ISO9001: 2015 certificated factory focusing on developing and manufacturing a two-shot plastic closure mouldfor household produc... | |

| 定制注塑ABS产品塑胶模具 | 中国塑料注塑模具制造厂定制注塑塑料件 一系列先进的设备,包括发那科数控机床、沙迪克电火花机、沙迪克线切割机、伊之密注塑机、蔡司三坐标测量机、易森2D投影仪、iMold自动化系统。我们将对所有注塑模具部件、铜和塑料注塑零件进行全尺寸测量。 | |

| Insert Molding | Plastic Insert Injection Molding Place of Origin: Guangdong, ChinaShaping Mode: Insert Metal Plastic Injection MoldingProduct Material: Plastic and... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |