Medical Test Tube Mold

As a container for nucleic acid detection, there is a huge amount of consumption every day in the world. How to produce with high efficiency and high quality is a difficult problem for medical products enterprises.

Medical Test Tube Mold

As a container for nucleic acid detection, there is a huge amount of consumption every day in the world. How to produce with high efficiency and high quality is a difficult problem for medical products enterprises.

High-quality Medical Test Tube Mold

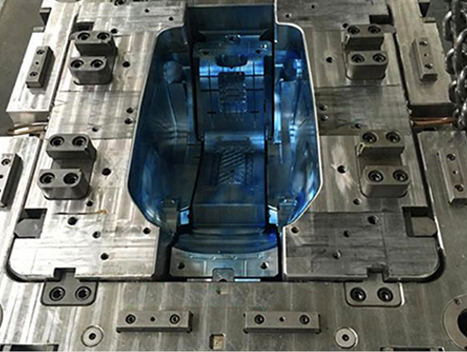

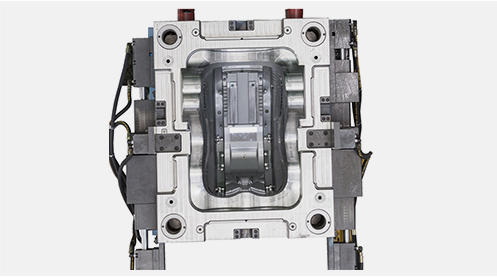

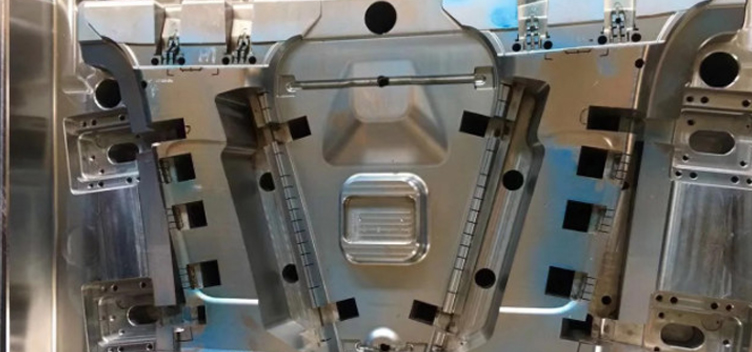

The Medical Test Tube Mold we have made is highly transparent, has no dent, high control precision, no eccentricity, with Excellent cooling system, reduces the molding cycle.

Basic Information for Medical Test Tube Mold

Test Tube MoldSpecification

|

Description |

Medical Test Tube Mold |

|

Plastic material |

PP,PS, PET,PE |

|

Tube specification |

Φ12.5*75/ Φ12.5*100/Φ13*100 |

|

Cavity No |

12-64 cav. |

|

Mould size |

660*500*478mm(32 cavities) |

|

Mold steel |

S136 |

|

Ejection system |

Needle valve gate |

|

Ejector system |

stripper |

|

Molding cycle (S) |

8-18s |

|

Mold life |

Min 5 million |

Our Advantages of Making Medical Test Tube Mold

Long mold life, is greatly higher than the low-end mold.

More cost-effective. The test tube mold is improved and optimized by the R&D team, with high technical content and good cost control.

Return on investment is higher. The customer's input and output ratio of nucleic acid test tube mold are several times higher than that of low-end mold.

Product quality is stable. S136 steel imported from Sweden is selected to manufacture, and advanced heat treatment and surface treatment technology are adopted to ensure the durability of the mold in the environment of high speed and high-pressure injection. Before mold production, mold flow analysis was used to analyze the forming defects of products, and then the mold structure was adjusted to improve the one-time pass rate of products.

Cavity core with self-locking structure, the same parts in the mold can be interchangeable; Reasonable cooling channel design, strengthen the cooling effect of the mold, effectively shorten the injection cycle.

What Are The Raw Materials Of Commonly Used Injection Molding Medical Products?

The most commonly used materials in the medical industry, polyvinyl chloride (PVC) and polyethylene (PE) accounted for 28% and 24%, respectively, polystyrene (PS) accounted for 18%, polypropylene (PP) accounted for 16%, and engineering plastics accounted for 14%. %. In engineering plastics, PET, SAN, PC, PMMA, PA, POM, and other materials are commonly used. These materials all have the following common characteristics of medical polymer materials:

Good physical and mechanical properties, which can meet the requirements of physiological functions and use environment;

It can withstand the sterilization process without affecting its biological and mechanical properties;

Good molding performance, easy to process into various shapes, and low cost;

The material is medical grade, with less heavy metal content and low content of leaching and leaching substances;

Non-toxic to the body, no pyrogen reaction, no "three causes" (carcinogenic, teratogenic, genetic mutation) effects, does not damage adjacent tissues, does not interfere with the body's immune mechanism, and does not cause material surface calcification;

When the material is in contact with blood, it has good anticoagulant properties, does not cause hemocytopenia after hemolysis, does not cause protein denaturation in blood, and does not destroy the formed components of blood;

When the material is implanted into the body, it has sufficient chemical stability and physiological inertness, and the physical and mechanical properties do not change significantly (excluding degradable materials).

If you need any kinds of plastic injection mold, please contact us, as a professional plastic injection factory, Green Vitality is willing to offer you high quality products.

在线联系供应商

Other supplier products

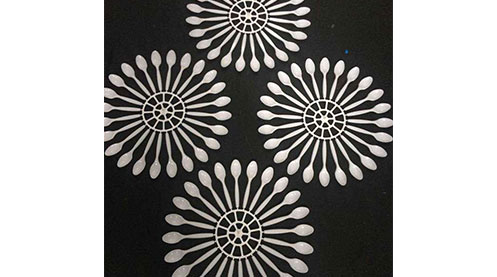

| Auto Part Mold | With the vigorous development of the automotive industry, plastic auto parts mouldis also developing rapidly. 90% of car parts mouldare produced by... | |

| Car Seat Mould for Kids | Child safety mouldy car seatsare seats specially designed to protect children from injury or death in a collision. The main structure of the child ... | |

| Plastic Spoon Mould | lastic spoon mainly used for eating, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental protectionso, w... | |

| Keyboard Mould | Mainly electronic molds we make are electronic housing mold, electronic components mold, electronic dashboard cover mold, computer keyboard mold, c... | |

| Injection Mold & Molding Parts Solution | Green Vitality Industry is a full-service mold manufacturer specializing in plastic injection mold design & engineering support, injection mold... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |