Plastic Injection Molding

What is plastic injection molding? Plastic Injection molding is a molding method that combines injection and molding. The advantages of plastic small scale injection moldingmethod are fast production speed, high efficiency, operation can be automated, variety of colors, shapes can be from simple to complex, size can be from large to small, and sizes of injection moulding supplies are accurate. The plastic injection moulding product is easy to update, and it can be made into complex shapes. Parts, injection molding/injection moulding is suitable for mass production and plastic molding processing fields such as products with complex shapes.

Plastic Injection Molding Basics

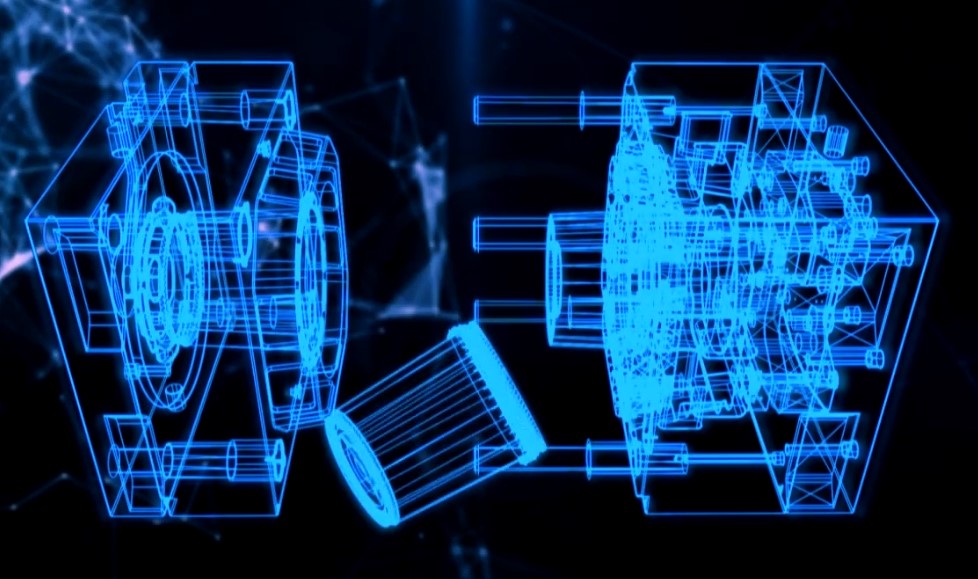

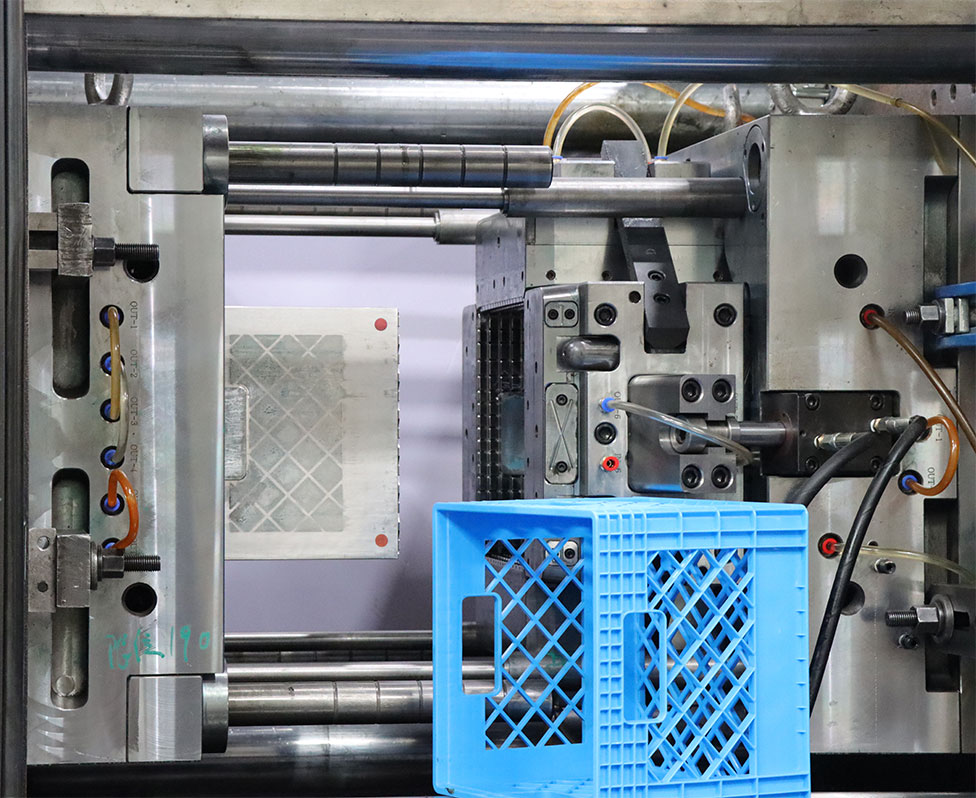

Keyplast plastic injection molding is a molding process that two metal mold halves (called core and cavity) come together and manufacture a formed part by injecting plastic materials into the cavity at a predetermined temperature and pressure, until left to cool and solidified to the shape of the mould.

As a professional injection moulding business in the plastic injection molding field, Keyplast plastic china injection mold factorynot only provides different types of injection mold toolings such as double shot molding, insert injection molding, overmolding injection molding and materials used in injection moulding with competitive injection molding prices, but offers custom injection molding as well.

Plastic Injection Molding Process

Plastic injection moulding chinais the process of melting plastic particles (thermosetting/thermoplastic polymers) and, once malleable enough, injecting them under pressure into a mold cavity, filling and curing to produce the final plastic injection moulding products.

How Does Plastic Injection Molding Work ?

The molding machine heats the plastic to a liquid state. The nozzle of the plastic injection machine then injects the melted plastic into the mold (injection pressure). The cavity of the mold is filled with plastic fluid and then cool to form a solid plastic molded product.

Plastic Injection Molding Technology

01

Cylinder temperature

The temperature that needs to be controlled during the injection plastic moulding process includes the temperature of the barrel, the temperature of the nozzle and the temperature of the mold, etc.

02

Nozzle temperature

The nozzle temperature is usually slightly lower than the maximum temperature of the barrel during the injection molding processs of plastic mold tooling, this is to prevent the "salivation phenomenon" that may occur in the straight-through nozzle of the molten material.

03

Mold temperature

The mold temperature has a great influence on the internal performance and apparent quality of the plastic mould tooling. The temperature of the mold depends on the crystallinity of the plastic, the size and structure of the product, and the performance requirements.

04

Injection pressure

In the current production of plastic moulds for sale, almost all the injection pressure of the injection machine is based on the plunger or the top of the screw to the plastic.

05

Plasticizing pressure (back pressure)

When using a screw injection machine to produce injection molds for sale, the pressure on the top of the screw when the screw rotates and retreats is called plasticizing pressure, also known as back pressure. The size of this pressure can be adjusted by the overflow valve in the hydraulic system.

Advantages Of Plastic Injection Moulding

在线联系供应商

Other supplier products

| Two Shot Molding | Two shot molding, also called double shot moulding, dual shot injection molding,multi shot injection molding or 2k injection moulding is one catego... | |

| Market Status Of China's Mold Manufacturing Industry | In recent years, due to the continuous improvement of China's industrialization, China has become a major mold manufacturing country and a major mo... | |

| Plastic Injection Molding | Plastic Injection Molding What is plastic small scale injection molding? Plastic Injection molding is a molding method that combines injection and... | |

| Types Of Plastic Injection Mold Polishing | Types Of Plastic Injection Mold Polishing Introduction to the plastic injection mold polishing These days, industrial products are developing in ... | |

| Injection Moulding Applications | Since 1980, Keyplast has involved in different industries and markets for 40 years. As a professional custom plastic parts manufacturer, we have ex... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |