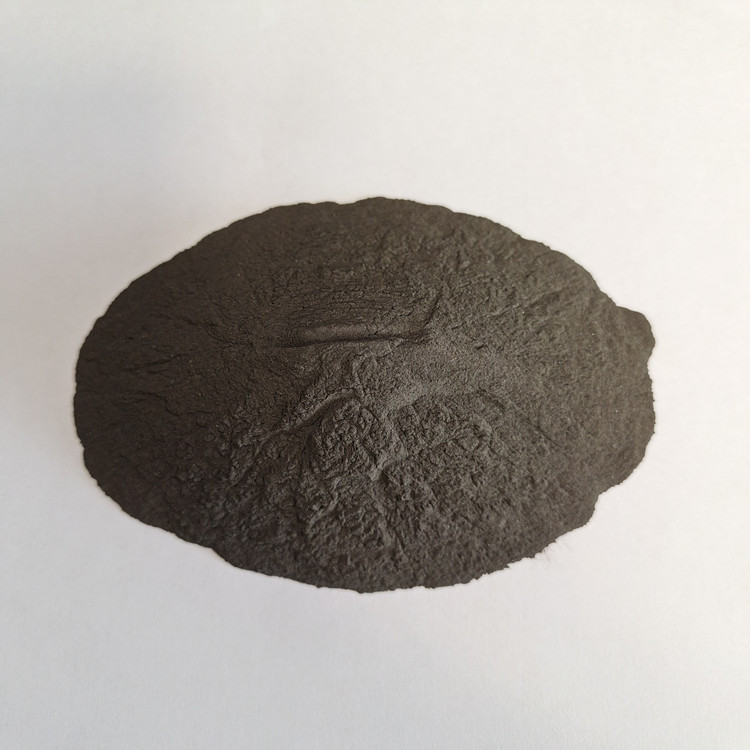

Carbon Raiser/Graphitized Petroleum Coke manufacture

Specifications:CPC/GPC

Shape:lumps/granule

Usage:Steelmaking

Particle size:Acording to your needs

Packaging:ton/ Bags

| Carbon Raiser | F.C% | V.M% | Ash% | S% | Moisture |

| CPC-01 | 98.5min | 0.5max | 0.3max | 0.45max | 0.3max |

| CPC-02 | 98.5min | 0.5max | 0.5max | 0.5max | 0.3max |

| CPC-03 | 98-99min | 0.5max | 1.00-0.3max | 0.5max | 0.3max |

| Both size and packing can be customized as your requests | |||||

Calcined petroleum coke (CPC) uses green petroleum coke as raw material. It is prepared by heating below 1400°C. The carbon content is about 98.5%. High conductivity and low resistance.

Graphite petroleum coke

Graphitized petroleum coke is the best carbon additive for smelting. High carbon, low sulfur, low nitrogen, high graphitization degree. And has a high carbon recovery rate (92% ~ 98%). The effect of increasing carbon content is stable.

| Carbon Raiser | F.C% | V.M% | Ash% | S% | Moisture |

| GPC | 98-99.5min | 0.5max | 0.3max | 0.05-0.03max | 1max |

| Both size and packing can be customized as your requests | |||||

There are many kinds of raw materials forCarbon Raiser , and the production processes are also different, including wood carbon, coal carbon, coke, graphite, etc., among which there are many small types under various classifications. High-quality Carbon Raiser generally refer to graphitized Carbon Raiser. Under high temperature conditions, the arrangement of carbon atoms is in the microscopic shape of graphite, so it is called graphitization

Graphitization can reduce the content of impurities in the Carbon Raiser, increase the carbon content of the Carbon Raiser, and reduce the sulfur content. Carbon Raiser are used in casting, which can greatly increase the amount of scrap steel. There are many kinds of raw materials for Carbon Raiser, and the production process is also different, including wood carbon, coal carbon, coke, graphite, etc., among which various classifications There are many smaller types below. High-quality Carbon Raiser generally refer to graphitized Carbon Raiser. Under high temperature conditions, the arrangement of carbon atoms is in the microscopic shape of graphite, so it is called graphitization.

Graphitization can reduce the content of impurities in the Carbon Raiser, increase the carbon content of the Carbon Raiser, and reduce the sulfur content. The use of Carbon Raiser in casting can greatly increase the amount of scrap steel and reduce the amount of pig iron or do not use pig iron.Calcined Pitch Coke Carbon Raiser price, HS code 38011000

In the feeding method of electric furnace smelting, the Carbon Raiser should be put in together with the charge such as scrap steel, and a small dose can be added on the surface of the molten iron. However, it is necessary to avoid feeding molten iron in large quantities, so as to prevent excessive oxidation and cause insignificant carbon increase effect and insufficient carbon content in castings. The amount of Carbon Raiser added is determined according to the ratio of other raw materials and the carbon content.

For different types of cast iron, choose different types of Carbon Raiser according to your needs. The characteristics of Carbon Raiser itself choose pure carbon-containing graphitized material to reduce excessive impurities in pig iron. The proper selection of Carbon Raiser can reduce the production cost of castings, reduce the amount of pig iron or do not use pig iron.

In the feeding method of electric furnace smelting, the Carbon Raiser should be put in together with the charge such as scrap steel, and a small dose can be added on the surface of the molten iron. However, it is necessary to avoid feeding molten iron in large quantities, so as to prevent excessive oxidation and cause insignificant carbon increase effect and insufficient carbon content in castings. The amount of Carbon Raiser added is determined according to the ratio of other raw materials and the carbon content.

For different types of cast iron, choose different types of Carbon Raiser according to your needs. The characteristics of Carbon Raiser itself choose pure carbon-containing graphitized material to reduce excessive impurities in pig iron. The proper selection of Carbon Raiser can reduce the production cost of castings.

在线联系供应商

Other supplier products

| Silicon carbon ball | Specifications:Si60C15/ Si65C18Shape: ball or blockUsage:SteelmakingParticle size:50mm or CustomizedPackaging:ton/ Bags Advantages of silicon carb... | |

| 碳化硅 | Specifications:FeMn88C0.2/ FeMn82C1.0/FeMn68C7.0 .etcShape: lumps Usage:SteelmakingParticle size:10-70mm or acording to your needsPackaging:ton/ Ba... | |

| Carbon Raiser/Graphitized Petroleum Coke manufacture | Specifications:CPC/GPCShape:lumps/granuleUsage:SteelmakingParticle size:Acording to your needsPackaging:ton/ Bags Carbon Raiser F.C% V.M% ... | |

| FeSi15 powder | Low ferrosilicon15% powder contain a small amount of silicon, It is made by electric furnace smelting after grinding process in the screening techn... | |

| Silicon metal 553/441 Price | Specifications: esi 65/70/72/75 etc.Shape: fesi lumps / powderUsage: SteelmakingParticle size: 10-100mmPackaging: ton/ Bags Chemical Componen... |

Same products

| Impregnated Graphite Electrode | 卖方: Zhongsheng Carbon Technology Co., Ltd | ZSCGraphite electrodeare manufactured with high quality raw materials including petroleum cokes,n... | |

| Graphite Heating Rod | 卖方: Zhongsheng Carbon Technology Co., Ltd | Graphite Heating Rodis Applied for industrial furnaces as structural or heating parts, like gra... | |

| Graphite Electrode Scraps | 卖方: Zhongsheng Carbon Technology Co., Ltd | The graphite scraphas different definitions in different materials. Some materials and literature... | |

| HP Graphite Electrodes | 卖方: Zhongsheng Carbon Technology Co., Ltd | Graphite electrode are manufacturedwith high quality raw materials including petroleum cokes, nee... | |

| UHP Graphite Electrodes | 卖方: Zhongsheng Carbon Technology Co., Ltd | Graphite electrodeare manufactured with high quality raw materials including petroleum cokes, nee... |