Eddy Current Testing for Auto Parts

NDTApplication:

Eddy current hardness testingtechnology has been widely used in the detection of metal components in the automotive The eddy current technology is usually used to detect engine blade cracks, bolts, cracks in the screw holes, multi-layer structure of the aircraft, landing gear, wheels and aluminum skin as the main NDT non destructive testing methods. And subsurface defects, and used to detect defects in the wing joint weld. In the detection, it can effectively suppress the shaking of the probe, and the material is uneven and cause interference signals. Metal magnetic memory testing technology can be used to diagnose the stress concentration of the above components or early damage.

GTET-02 Cylinder Liner Eddy Current Testing Machine

Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02

During the processing of bearing rings, various defects are often generated on the surface or inside, and cracks occupy a large proportion in all defects. The cause of the cracks in the bearing rings

BKNET Series Multi-frequency and Multi-filter Eddy Current Flaw Detector

In the field of parts crack and grinding burn detection, the multi-frequency and multi-filter technology developed by BKNis a great breakthrough in the field of global eddy current technology.

BKNFX Pre-Multi-Frequency Eddy Current Hardness Separator

Stimulating coil makes magnetic induction to the tested material. The induced electromotive force received by the testing coil is related to the shape and size of the material hysteresis loop. When the...

Bolt Eddy Current Sorter BKNFX-11

Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external thread) is required to be fitted with a nut for

Connecting rod hardness eddy current sorting machineLGYDFX-01

The connecting rod hardness sorting instrument has a calibration device, input compensation parameters, automatic/manual temperature

ET-F1 Engine Cylinder Bore Eddy Current Flaw Detector

The eddy current non destructive testingmachine consists of an instrument system, rotating probe system, probe servo system (including probe floating device), detection and positioning system, electrical control system, etc.

Flame Quenching Engine Valve Rod End Eddy Current Hardness Separator QMYDFX-01

GZET-01 Roller Automatic Eddy Current Flaw Testing

The rolling element has a large surface contact stress during operation, so the quality of the rolling element has an important influence on the life and performance of the bearing.

HSXET-02 Piston Pin Eddy Current Tester

The piston pin is a cylindrical pin that is mounted on the skirt of the piston. Its middle part passes through the small hole of the connecting rod and is used to connect the piston and the connecting rod.

Hub Bearing Eddy Current Flaw Detector LGTSET-AB

The hub bearing is one of the key components of the car. Its main function is to carry the weight and provide precise guidance for the rotation of the hub.

Piston Rod Eddy Current Flaw Detector HSGET-04

The two piston rollers rotate in the same direction to drive the upper piston rod to rotate, and then the push rod pushes the piston rod through the probe to complete the detection.

Precision Axis Eddy Current Flaw Detector JMZET-04

The two piston rollers rotate in the same direction to drive the upper piston rod to rotate, and then the push rod pushes the piston rod through the probe to complete the detection....

QTXET-01 Ball Studs Eddy Current Sorting Machine

There are two main types of ball studs: one is a combination of a spherical pin and an integral ball seat, and the other is a combination of a hemispherical ball pin and a spherical member.

QTXFX-01 Ball Studs Eddy Current Hardness Separator

Should have sufficient swing angle to meet the requirements of the wheel up and down; Smaller frictional moments are important factors in ensuring steering flexibility...

Roller Eddy Current Hardness Separator GZYDFX-01

It is suitable for sorting and testing the hardness and material of cylindrical steel parts such as cylindrical rollers, tapered rollers and needle rollers, and realizes zero defect control of the

SCPET-04 Brake Disc Eddy Current Flaw Detector

Brakes currently have disc brakes and drum brakes as well as air brakes. Many older cars are front and rear drums. Many cars are now disc brakes. Because the disc brakes have better heat

Steel Ball Hardness Eddy Current Sorter GQYDFX-01

The eddy current hardness sorter is an instrument for measuring the hardness of a workpiece based on the principle of eddy current testing. Usually used to measure the hardness of steel, sorting the

Tapered Roller Online Eddy Current Flaw Detector YZGZET-01

Tapered roller bearings are separate bearings, and the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into different structural types...

TLET-04 Camshaft Eddy Current Flaw Detector

Surface roughness:>1.6 Detectable crack size: 3mm*0.01mm*0.1mm (length*width*depth) Detectable hole size:¢0.7mm*0.7mm (diameter *depth) Detection rhythm: 5 seconds per beat

TLZET-99 Camshaft Eddy Current Flaw Detector

The camshaft is a component of the piston engine. Its role is to control the opening and closing of the valve.

Valve Tappet Eddy Current Flaw Detector QMTZET-04

Tappet full automatic eddy current testing system is a full automatic crack hardness sorter which integrates light, electricity and machinery.

BKNMAG+CONVEY Automatic Magnetic Pole Detector

This system is suitable for the pole detection of block and strip magnetic materials and can realize the sorting of magnetic pole errors. The equipment is automatically detected, automatically sorted,...

BKNMAG+PLUS Magnetics Magnetic Pole Detector

This system is suitable to be installed on the AOI visual inspection machine to cooperate with the vision sorting machine; to realize the sorting of the wrong magnetics magnetic pole. The system can a...

BKNMAG+GLASS PLATE Automatic Magnetic Pole Detector

This system is suitable for the detection of the magnetic pole of small magnetics and can realize the sorting of the wrong magnetic pole of the magnetics. The whole set of equipment is automatically d...

BKNMAG+GLASS PLATE Automatic Magnetic Pole Detector

Due to the complex geometry of the auto parts, the equipment is required to have a high level of materials and complicated materials, requiring diverse equipment and high precision. In addition, the production of auto parts is a large industrial production, with certain beat monitoring requirements, and only by reducing the testing costs, can we reduce the automobile production and improve the competitiveness in the domestic and foreign markets. With the development of the national economy, the automobile industry has become a pillar industry in China. Therefore, non-destructive testing technology for eddy current flaw detectors for automotive parts is also receiving increasing attention from manufacturers and researchers. At present, the most widely used non-destructive testing method in the detection of automotive parts is the eddy current flaw detector ultrasonic testing method. In the ultrasonic flaw detection of eddy current flaw detectors at home and abroad, the most used type A ultrasonic flaw detector. It adopts A-type ultrasonic display, which has the advantages of simple and cheap equipment, can locate and quantify defects, and is widely used in production inspection.

However, its flaw detection results are not intuitive, no record, difficult to detect, and many human factors. Seriously affect the reliability of detection. Due to the continuous development of computer technology and electronic devices, the digital acquisition and analysis of the ultrasonic signal of the eddy current flaw detector become possible, the waveform can be recorded and preserved, and the ultrasonic detection of the eddy current testing instrument is positive digital signal processing and imaging direction development. Super-generation image technology is a remarkable new technology. The ultrasonic image of the object can provide intuitively and a large amount of information, directly reflecting the acoustic and mechanical properties of the object, and can also evaluate the mechanical properties of the microstructure of the solid material. Suddenly macroscopic discontinuities.

In short, the NDT non-destructive testing method for automotive parts eddy current flaw detector will develop with the advancement of modern high-tech, to the direction of intelligence, automation and imaging, in order to adapt to the rapid development of modern automobile manufacturing industrial parts quality inspection, testing requirements.

As a NDTmachinemanufacturer and supplier, we have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

If you want to know more about application of eddy current testing, please visit our website.

在线联系供应商

Other supplier products

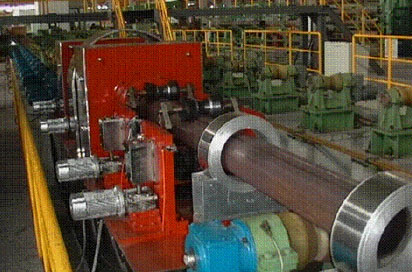

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. A... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. A... | |

| Drill Pipe Magnetic Flux Leakage Detector MFL-308 | Specifications: diameter Φ73 / Φ89 mm, length 9.6m or so Detection speed: 6-20 m / min Acceptance criteria: American Petroleum Institute ... | |

| Steel Bar Testing | The steel bar is rolled by a rolling mill and produce both surface defects and internal defects during the rolling process. The internal defect is ... | |

| MFL101 Tank Floor MFL Scanner | Technical Characteristics of MFL101 Tank Floor MFL Scanner The mfl scannerhas a unique full modular structure, from the main body of the compute... |

Same products

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | 卖方: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | 卖方: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | 卖方: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | 卖方: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |