STEEL PIPE END EXPANDING MACHINE

Pipe expanding machineis a professional equipment for expanding and rounding the end of spiral submerged arc welded steel pipe, mainly used in oil and gas and fluid transmission pipelines to help pipe expanding and rounding. And the pipe end expanding machine has the characteristics of high efficiency, compact structure, high strength and good stability, suitable for the place with high processing accuracy requirements.

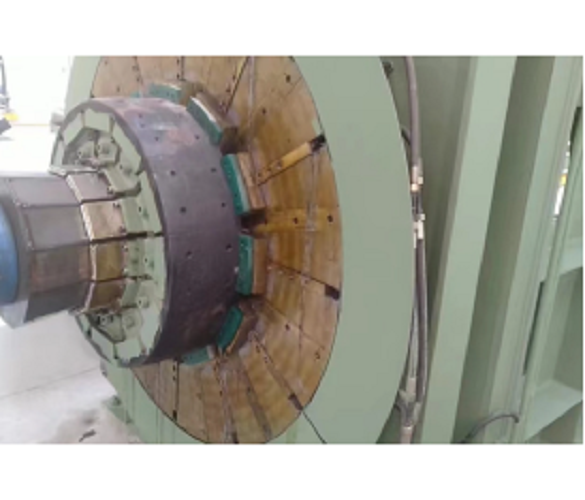

Pipe end expanding machine belongs to the metal welded pipe shaping equipment, it is a cone expansion head, expansion in the steel pipe, to eliminate the forming pressure and welding stress of the steel pipe, and ensure that the diameter of the welded pipe end is consistent. The hydraulic pipe expander machineis composed of a trolley, an expander, a working sleeve, a fixed seat, an oil cylinder, a lubricating station, a bench, a hydraulic station and an electronic control system. The expander is arranged in the trolley, the expander is connected to the oil cylinder by a working sleeve, and the expander is composed of an expansion head, an expansion block, a guide disk, a pull rod, etc. It is a large equipment of steel pipe testing & expanding machine to ensure the shape diameter of straight seam metal welded pipe and eliminate stress through the segmented mechanical extrusion process.

ADVANTAGES OF STEEL PIPE END EXPANDING MACHINE

The use of mechanical expanding machine to expand the steel pipe has the following advantages: regardless of the wall thickness and yield strength can produce a constant inner diameter of the steel pipe; Mechanical expansion can expand steel pipes with thick walls, high yield strength and large diameters, because only one section of steel pipe is expanded at a time; The diameter of the short pipe can be expanded without adjustment within the specified scope; The die of the mechanical expanding head can be adjusted to the steel pipe with a certain range of wall thickness without replacing the expanding die; High efficiency in the production of large diameter steel pipes.

During the expansion period, the steel pipe can be visually observed, if the steel pipe is broken, the expansion can be immediately stopped to prevent the spread of the broken part, and the expansion can be carried out again after removal or repair; The end of the steel pipe is round and has a precise size, and the end of the steel pipe will not be indented; The expanding die can be adjusted to compensate for wear.

STEEL PIPE END EXPANDING MACHINE EQUIPMENT COMPOSITION

The mechanical expanding machine is composed of a rotating roller device, a lifting tapered roller table, a transmission pull rod sleeve support roller, a length measuring roller, a clamping trolley, an expanding head, a pull rod, a pull rod sleeve, a hydraulic cylinder and a frame of the expanding machine, etc. The role of the mechanical expanding machine is to use the expanding head to expand the large-diameter LSAW pipe step by step to obtain the roundness, straightness, and dimensional accuracy required by the standard technology.

Equipment Composition of Mechanical Expanding Machine

The diameter expanding machine belongs to straight seam metal welded pipe shaping equipment. It uses a cone expansion head to expand in the steel pipe to eliminate the forming pressure and welding stress of the steel pipe and ensure that the true diameter of the straight seam welded steel pipe is consistent throughout the length. The equipment consists of trolley, expander, working sleeve, fixed seat, oil cylinder, lubrication station, bench, hydraulic station and electric control system. The expander is set on the trolley, and the expander is connected to the oil cylinder by the working sleeve. The expander is composed of an expansion head, an expansion block, a guide plate, a tie rod and so on. It is a large-scale equipment that ensures the shape and sizing of straight seam metal welded pipes and eliminates stress through the segmented mechanical expansion process.

Hebei Tianxianghao Metallurgical Equipment Manufacturing Co., Ltd. is a comprehensive enterprise specialized in manufacturing spiral welded steel pipe production line, high-frequency welded pipe production line, pipe hydrostatic testing machine, pipe beveling machine. We located in Yanshan, China, "China Pipeline Equipment Manufacturing Base".

在线联系供应商

Other supplier products

| STEEL PIPE DROPPER | This machine is a lifting device used in the steel pipe conveying process, used to lift the steel pipe onto the steel conveying roller after produc... | |

| STEEL PIPE DROPPER | This pipe droppermachine is a lifting device used in the steel pipe conveying process, used to lift the steel pipe onto the steel conveying roller ... | |

| 3PE ANTI-CORROSION STEEL PIPE PRODUCTION LINE | The 3LPEAnti-corrosion Steel Pipe Production Line Chinais a specialized system used for manufacturing steel pipes with a triple-layer coating desig... | |

| Products | SSpipe machineis a manufacturing system that is used to produce different types of steel pipes, such as spiral welded pipes, longitudinal welded pi... | |

| INDUSTRIAL X RAY EQUIPMENT FOR STEEL PIPE INSPECTION | The pipe X ray machine for spiral steel pipes is suitable for non-destructive testing of the quality of spiral steel pipe welds. The industrial xra... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |