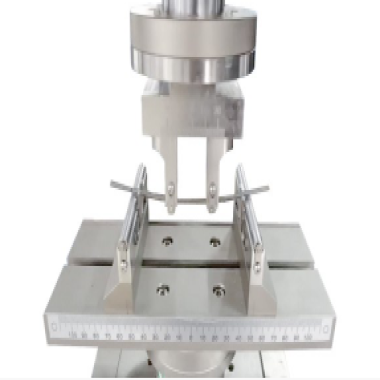

Micro Controll High-temperature Friction Tester

Main Purposes

The microcomputer - controlled high - temperature friction testing machine is a device specifically designed for testing the frictional properties of materials in high - temperature environments. Its main purposes include, but are not limited to, the following aspects:

Material R & D and Evaluation

- Used to evaluate the friction and wear properties of various materials under high - temperature conditions, including metals, non - metals, coatings, rubbers, plastics, ceramics, etc.

- Helps in the research and development of new high - temperature - resistant materials and improves the high - temperature frictional properties of materials.

Lubricant and Oil Product Testing

- Test the frictional properties of lubricants, hydraulic oils, internal combustion engine oils, gear oils, etc. at high temperatures, and evaluate their lubrication effects and anti - wear capabilities. - Provide data support for the R & D, improvement, and quality control of lubricants and oil products.

Durability Testing of Mechanical Components

- Simulate the actual working conditions of mechanical components in high - temperature environments, test their friction and wear properties, and evaluate the durability and reliability of the components. - Contribute to optimizing mechanical designs and improving the service life and performance stability of mechanical components.

Aerospace and Automotive Manufacturing Applications

- Test the frictional properties of aerospace vehicles and automotive components in high - temperature environments to ensure their reliability and safety under extreme conditions. - Provide a basis for material selection, performance optimization, and quality control in the aerospace and automotive manufacturing industries.

Applicable Standards

When conducting tests, the microcomputer - controlled high - temperature friction testing machine usually needs to comply with the following relevant national or international standards: - GB/T series standards: Relevant regulations on friction and wear testing in Chinese national standards, such as GB/T 12583 - 98 *Method for Determination of the Extreme - Pressure Properties of Lubricants (Four - ball Machine Method)*, etc.

Technical parameters:

Maximum test force 100KN

Tester accuracy 0.5 level

Test force measurement range 0.2%-100%FS All the way without gearing

Test force accuracy ±0.5% or less

Test force resolution 1/±300000 of the maximum test force (the whole resolution is unchanged)

Deformation measurement range 0.2%-100%FS

Relative error of the deformation value of the value of ±0.5% or less Within ±0.5%

Distinguishing power of deformation 1/±300000 of the maximum deformation

Dimensions of high and low temperature chamber 300mm*300mm*400mm

Temperature range Room temperature~600℃

Temperature fluctuation ±1℃

Relative error of displacement ±0.5% of the indicated value

Distinguishing power of displacement 0.05μm

Adjustment range of force rate 0.01-5%FS/S

Relative error of force rate ±0.5% of the setting value 0.5% of set value Within ±0.5% of set value

Transformation rate adjustment range 0.02-5%FS/S

Relative error of transformation control rate Within ±0.5% of set value

Transverse beam speed adjustment range 0.01-500mm/min

Relative error of transverse beam speed Within ±1.0% of set value for speed < 0.01mm/min; within ±1.0% of set value for speed ≥ 0.01mm/min. mm/min, within ±0.2% of the set value

Control range of constant force, constant deformation and constant displacement 0.5%-100%FS

Control accuracy of constant force, constant deformation and constant displacement When the set value is <10%FS, it is within ±1% of the set value; when the set value is ≥10%FS, it is within ±0.1% of the set value

Effective tensile space 700mm

Effective test width 600mm

Main machine appearance Dimensions (L×W×H) 800×600×2000 (mm)

Power supply 220V±10%,50Hz

Weight of mainframe about 500kg

在线联系供应商

Other supplier products

| Electric hook core bending resistance testing machine | The electric hook core anti-bending performance tester is used to test the anti-bending performance of the steel hook core. Insert the hook core in... | |

| Helmet Surface Friction Testing Machine | Helmet Surface Friction Testing Machine - Material and Parts of Automotive - standard Standards: ECE R22.05 Applications: The Helmet Surf... | |

| Sponge foam collapsible hardness tester | Purpose: This machine is used to measure the indentation hardness of porous elastic materials. The polyurethane foam sample can be tested accordin... | |

| Pinch Fold Tester | Standards: LP-463KB-28-01 Method C,TSL 5100G Section 4.29 Applications: This pinch fold tester is designed to conduct Chrysler LP-463KB-28-01typ... | |

| Spinal Internal Fixation System Component Testing Machine | Standard YY/T 0119-2014 (China): Specifies mechanical testing protocols for spinal fixation components, including screws, plates, rods, and conn... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |