Standard pacifier safety tester

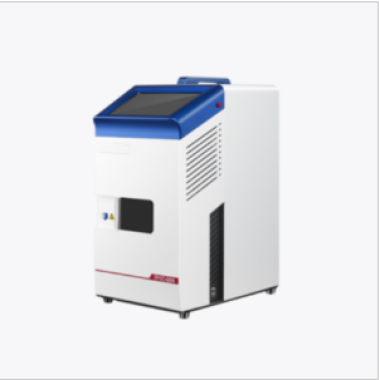

Overview:

In the infant care industry, bottle quality directly impacts infant health. The NPNZ-01 Baby Bottle Mechanical Performance Tester is specifically designed to ensure product safety through precise mechanical testing. Compliant withGB 38995-2020 "Infant Bottles and Nipples", it features customized fixtures and test programs for comprehensive mechanical performance evaluation, including:

- Tensile strength testing

- Needle puncture resistance

- Pressure resistance deformation

- Flexibility testing

- Safety retention force measurement

Beyond baby bottle testing, its advanced technology and modular design enable broad application in:

Applications:

| Industry Sector | Test Capabilities | Key Parameters |

|---|---|---|

| Baby Care | Bottle/nipple mechanical performance | Tensile strength, puncture resistance, deformation tolerance |

| Pharmaceutical Packaging | Seal integrity testing | Closure torque, puncture force, extraction force |

| Medical Devices | Syringe performance | Slip resistance, breakage force, sealability |

| Healthcare Products | Catheter testing | Connection strength, opening torque, pressure resistance |

Technical Advantages:

The NPNZ-01 system demonstrates superior performance through:

- High precision sensors: ±0.5% measurement accuracy

- Multi-functional fixtures: 15+ interchangeable test heads

- Intelligent software: Auto-calibration, data analysis, and compliance reporting

- Safety features: Overload protection, emergency stop, and data encryption

Compliance & Certification:

Certified to international standards including:

- GB 38995-2020 (China)

- ISO 10993 (Biocompatibility)

- ASTM F963 (Toy safety)

- EN 71-1

Why Choose NPNZ-01 ?

Key benefits for manufacturers:

- Quality assurance: 100% compliance with national/international standards

- Efficiency: 50% faster testing cycles compared to traditional methods

- Cost savings: Reduced material waste through precise defect detection

- Market competitiveness: Certification-ready reports for global market access

在线联系供应商

Other supplier products

| Mask Breathing resistance testing machine EN149-2009 section 7.15 EN 13274-3 | Standards: EN149-2009 section 7.15. 8.3.4. EN 13274-3. GB 19083. GB 2626. NIOSH 42 CFR Part 84. JIS/T 8151 Mask Breathing resistance testing mach... | |

| Safety shoe impact testing machine | According to the criteria: Bs-953,1870,EN-344,ANSI-Z41,CSA-Z195 ISO K88782 Technical parameters: Weight of drop hammer: (EN) 20±0.2kg,(... | |

| Textile Thermal Insulation Property Tester | Standard GB/T 41560-2022 (China): Specifies thermal resistance testing protocols for protective clothing and industrial fabrics. BS 6526:... | |

| 20L Spherical Explosion Tester | The 20L Spherical Explosion Tester is a state-of-the-art laboratory instrument designed for the precise evaluation of the explosion characteristics... | |

| Microscale Continuously Closed Cup Flash Point Analyzer/ Micro Closed Cup Flash Point Tester/ ASTM D3828 Flash Point Tester | Reference Standards: SH/T 0768, SN/T 3077.1, DL/T 1354, ASTM D6450 SN/T 3077.2, ASTM D7094 GB/T 261, GB/T 21615, ASTM D93 GB/T 5208, GB/T 21790, A... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |