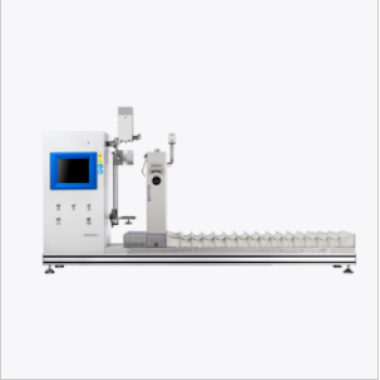

Micro Rapid Closed Cup Flash Point Tester(Pensky Martens)

Automatic Flash Point Tester designed for accurate and repeatable determination of the flash point of petroleum products using the Pensky-Martens closed cup method, fully compliant with ASTM D93.

The flash point of a material is the lowest temperature at which it emits enough vapor to ignite in air in the presence of an ignition source. It is a critical parameter for determining the flammability and safety classification of fuels, oils, solvents, and other volatile substances.

Applications

Petroleum & Petrochemical Industry – Testing fuels, base oils, lubricants

Paints & Coatings – Verifying solvent flash points

Pharmaceuticals & Chemicals – Assessing flammability characteristics

Transport & Safety Compliance – Ensuring materials meet regulatory flash point requirements

Environmental & Quality Labs – Standardized material classification

Standards

SN/T 3077.1-2012: Chemicals—Determination of flash point—Part 1: Closed-cup equilibrium method

SN/T 3077.2-2012: Chemicals—Determination of flash point—Part 2: Closed-cup rapid equilibrium method

SH/T 0768-2005: Determination of total contaminants in middle distillate fuel oils—High-temperature filtration method

DL/T 1354-2014: Preparation method of working standard oil for analysis of dissolved gas components in transformer oil

ASTM D93: Pensker-Martins closed-cup flash point determination

ASTM D6450: Small closed-cup flash point determination method

ASTM D3828: Small closed-cup device method for determining the flash point of liquids

ASTM D7094: Improved continuous closed-cup flash point determination method

ASTM D7236: Improved Abel closed-cup flash point determination method

ASTM D56: Tiger closed-cup flash point determination method

ISO 2719: Petroleum products—Determination of flash point—Pensker- Martins Closed Cup Method

ISO 13736: Petroleum Products - Determination of Flash Point - Abel Closed Cup Method

ISO 1516: Petroleum Products - Determination of Flash Point - Tiger Closed Cup Method

ISO 1523: Petroleum Products - Determination of Flash Point - Small Closed Cup Method

IP 34: Determination of Flash Point - Abel Closed Cup Tester Method

IP 304: Determination of Flash Point - Small Closed Cup Method

IP 170: Determination of Flash Point - Pensker-Martins Closed Cup Tester Method

DIN EN 22719: Petroleum Products - Determination of Flash Point - Pensker-Martins Closed Cup Method

JIS K2265: Petroleum Products - Determination of Flash Point

NF M 07-019: Petroleum Products - Determination of Flash Point - Pensker-Martins Closed Cup Method

Features

1. It adopts the advanced continuous closed - cup flash - point test method, which is more accurate and efficient.

2. It requires a small sample amount, resulting in low test costs and minimal pollution.

3. With continuous closed - cup operation, there is no open flame, ensuring high safety.

4. It has a built - in refrigeration module, offering a wide flash - point test range and a fast cooling rate.

5. Standard test methods are preset and can be associated with other closed - cup methods.

6. It features fully automated detection and automatically corrects the flash - point based on atmospheric pressure.

7. It displays temperature and pressure curves in real - time, making the test process more intuitive.

8. The test results include a temperature - pressure rise curve, providing more information about flash combustion.

9. Key components are from well - known international brands, ensuring long - term stable operation.

10. It supports user - level management, enabling the management and control of accounts at different levels.

11. The USB interface is plug - and - play. An optional thermal printer is available for convenient data management.

12. It is equipped with a 7 - inch color touch screen that supports Chinese input, making the operation intuitive and simple.

Technical Parameters

|

Operating Environment |

(5~40)℃, <85%RH |

|

Temperature Range |

(0~260)℃ |

|

Rising Rate |

(-30~260)℃ (with low-temperature module) |

|

Temperature Detection Accuracy |

(0~420)℃ (with high-temperature module) |

|

Pressure Detection Range |

(-30~420)℃ (with low-temperature and high-temperature modules) |

|

Sample Volume |

(2.5±0.3)℃/min, (5.5±0.5)℃/min, |

|

Ignition Method |

(0.5~12)℃/min Customized |

|

Stirring Speed |

±0.1℃ |

|

Storage Space |

(0~200)kPa |

|

Interface |

1mL or 2mL |

|

Power |

High-pressure electronic ignition |

|

Power |

(50~300)rpm software can be set |

|

Dimensions |

5000 test results |

|

Weight |

RS232*1. RJ45*1. USB*2 |

Accessoriess

1. Binsky-Martin Closed Cup Kit (includes a dedicated cup body and sealing cap, suitable for closed cup testing requirements)

2. Micro-sample pipette (matches the instrument's micro-sample volume injection requirements)

3. Spare ignition needle/igniter assembly (a spare part to ensure stable ignition function)

4. Sealing ring for closed cup (a consumable sealing component for closed cup testing)

5. Spare temperature sensor probe (a core spare part for temperature detection)

6. Standard flash point sample for calibration (a known flash point standard oil compatible with ASTM D93, used for instrument calibration)

7. Dedicated cleaning tools (such as brushes and wiping cloths, for cleaning and maintenance of components such as the cup body)

Test Procedures

Procedure A: For fuels and liquids with flash points between 40°C and 360°C

Procedure B: For materials with potential surface films or those prone to forming skin

Procedure C: For biodiesel blends and other specified fuel mixtures

在线联系供应商

Other supplier products

| ASTM G154 UV Accelerated Aging Chamber丨UV Accelerated Aging Chamber | Features and Benefits 1.TheUV accelerated aging chamberuses fluorescent ultraviolet lamps to simulate the ultraviolet part of sunlight: the UVA3... | |

| Spray Aerosol Ignition Distance Tester | Product Description Conforms to UN Recommendations on the Transportation of Dangerous Goods - Manual of Tests and Criteria 31.4 Ignition Distance ... | |

| Micro-hole Detection Instrument | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in aluminum foil materials. The following is a detail... | |

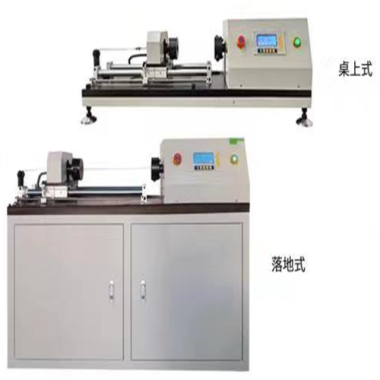

| Wire Torsion Tester | Applicable standards: GB/T 239.1-2012 "Metal materials wire Part I unidirectional torsion test method" GB/T 239.2-2012 "Metal materials wire Part... | |

| Rubber Low Temperature Brittleness Tester | The Rubber Low Temperature Brittleness Tester determines the temperature at which rubber and plastic samples become brittle under impact conditions... |

Same products

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | 卖方: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | 卖方: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | 卖方: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | 卖方: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |