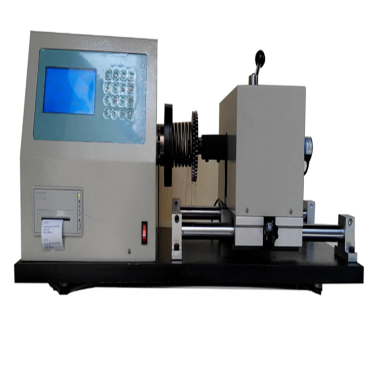

Spring torsion tester

The Spring Torsion Tester is designed to precisely measure torsional properties, including torque and angle, for a wide range of torsion springs and components. It provides accurate, reliable data essential for quality control, design optimization, and research and development. The instrument supports testing according to recognized national and international standards, ensuring compliance and consistency in industrial, scientific, and educational applications.

Application

(1) Measuring torsion angle and torque of large torsion springs.

(2) Testing torsional stiffness and critical torsional properties of spring components.

(3) Torsion testing of mechanical parts and assembled components with appropriate fixtures.

(4) Quality control in manufacturing industries.

(5) Verification of torsional performance in mining and heavy machinery equipment.

(6) Material testing for industrial and scientific research.

(7) Testing for technical supervision and commodity inspection agencies.

(8) Educational and laboratory applications in universities and research institutes.

(9) Product design and R&D for optimizing torsional components.

Standards

(1) JB/T 9370-1999 – Torsion testing machine standard and material test method.

(2) JJG 269-2006 – National metrological verification regulation for torsion testing machines.

(3) ISO standards for torsion testing of springs and materials.

(4) JIS standards for torsion measurement of springs.

(5) ASTM standards for torsion testing of metallic and non-metallic springs.

(6) DIN standards for torsional property testing.

Features

(1) Accurate Measurement: High-precision measurement of torque and torsion angle.

(2) Determines Torsional Properties: Essential for assessing torsional stiffness and material performance.

(3) Versatile: Capable of testing a wide range of torsion springs and components.

(4) Quality Control: Ensures compliance with specifications and reliable product performance.

(5) Supports Design and R&D: Provides critical data for optimizing spring and component designs.

(6) Standard Compliance: Facilitates testing in accordance with recognized international and national standards.

(7) PLC Control System: Ensures stable operation and easy parameter adjustment.

Parameters

| Parameter | Specification |

|---|---|

| Test force (N·m) | 10, 20, 50, 100, 200 |

| Minimum torque readout (N·m) | 0.001, 0.01, 0.1 |

| Minimum angle readout | 0.1° |

| Relative error of torque indication | ≤ ±1% |

| Torque zero error | ≤ ±0.1% |

| Effective testing space | 160 mm |

| Fixture centerline coaxiality | ≤ φ1 mm |

| Control system | PLC |

| Power supply | AC 220V, 50Hz |

Accessories

(1) Main testing machine

(2) Torque fixtures for different spring sizes

(3) Angle measurement clamps

(4) Control panel with PLC interface

(5) Power cable

(6) User manual

Test Procedures

(1) Secure the spring or component in the appropriate torsion fixture.

(2) Set the desired test parameters, including torque range and angular measurement resolution.

(3) Activate the PLC control system and begin the torsion test.

(4) Monitor torque and angle readings throughout the test for accuracy.

(5) After completion, stop the machine and carefully remove the test sample.

(6) Record the measured data for evaluation and quality assessment.

(7) Repeat the procedure for additional samples or different torque ranges as needed.

Maintenance Information

(1) Regularly inspect fixtures, clamps, and moving components for wear or damage.

(2) Lubricate rotating and sliding parts according to manufacturer recommendations.

(3) Clean the testing area and components after each test to remove debris.

(4) Periodically check electrical connections and PLC system for proper operation.

(5) Store the instrument in a clean, dry, and vibration-free environment when not in use.

(6) Follow operational safety guidelines to prevent injury during testing.

在线联系供应商

Other supplier products

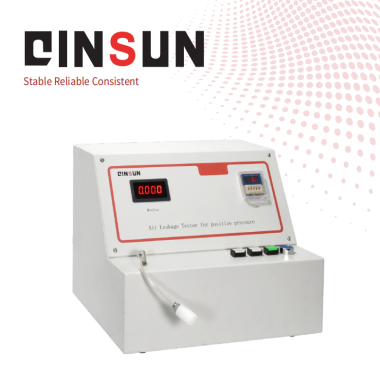

| Infusion Apparatus Leakage Positive Pressure Tester | The M102 Infusion Apparatus Leakage Positive Pressure Tester is designed to evaluate the airtightness and sealing performance of medical injection ... | |

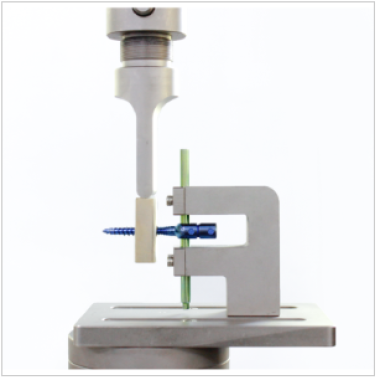

| Bone Plates Static Four - point Bending Tester | Standard YY/T 0342-2022: Chinese standard specifying methods for determining bending strength and equivalent bending stiffness of straight and pre... | |

| Conveyor Belt Drum Friction Test chamber | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction testing machine has extensive application value in mu... | |

| Oxidizing liquid time pressure tester | Conforms to UN Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria 11.6.1 Test 1(c)(i): Time/Pressure Test, 12.6.1 T... | |

| Helmet Wearing Height Testing Machine | Main Purposes Measure the wearing height of helmets to ensure the accuracy and safety of helmet - wearing positions. Standard EN 397 GB 2812 Ce... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |