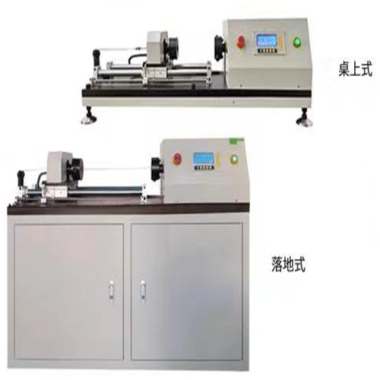

Torsion Testing Tester

The Universal Torsion Testing Machine is a precision instrument designed to measure torque and evaluate the mechanical properties of materials and components under torsional loads. It is capable of testing a wide range of specimens, including springs, wires, tubes, bars, and chains. The machine supports both unidirectional and bidirectional torsion, making it suitable for diverse applications in quality control, research, and production environments.

Application

(1) Measuring torsional strength and ductility of wires, bars, tubes, springs, and other components.

(2) Evaluating torsional fatigue and performance under repeated twisting cycles.

(3) Quality control of metallic materials in manufacturing and production lines.

(4) Research and development of new materials requiring torsional property assessment.

(5) Testing left-hand and right-hand torsion for engineering components.

(6) Laboratory testing for educational and scientific research purposes.

Standards

(1) GB/T 239.1-2012 – Metal Materials Wire Part I: Unidirectional Torsion Test Method.

(2) GB/T 239.2-2012 – Metal Materials Wire Part II: Bidirectional Torsion Test Method.

(3) ISO 7800:2003 – Test Method for Unidirectional Torsion of Metal Wires.

(4) ISO 9649:1990 – Test Method for Bidirectional Torsion of Metal Wires.

(5) ASTM, JIS, and DIN standards related to torsion testing of metallic materials.

Features

(1) Evaluates torsional ductility and maximum torsional strength.

(2) Supports both unidirectional and bidirectional torsion tests.

(3) Reveals material defects and inconsistencies under torsional stress.

(4) Compliant with multiple national and international standards.

(5) Provides controlled and repeatable testing parameters, including twisting speed and sample length.

(6) Suitable for a wide variety of materials, including wires, bars, tubes, springs, and chains.

(7) Versatile testing capabilities for torsion, breakage, and fatigue analysis.

Parameters

| Parameter | Specification |

|---|---|

| Clamping wire diameter range | 3.0–5.0 mm |

| Distance between fixtures | 500 mm |

| Twisting speed | 30–60 r/min |

| Power supply | AC 220V, 50Hz |

| Noise level | <70 dB(A) |

Accessories

(1) Main torsion testing machine

(2) Sample clamps for different diameters

(3) Adjustable fixture supports

(4) Power cable and user manual

Test Procedures

(1) Secure the specimen between the two clamps.

(2) Set the torsion mode: unidirectional or bidirectional.

(3) Adjust the twisting speed and number of rotations as required.

(4) Start the test; for unidirectional torsion, the sample rotates 360° in one direction until the specified cycles or failure.

(5) For bidirectional torsion, the sample rotates 360° in one direction, then reverses for the same number of cycles until failure.

(6) Record torsion angle, torque, and failure data for analysis.

Maintenance Information

(1) Inspect clamps, fixtures, and moving parts regularly for wear or misalignment.

(2) Keep the machine clean and free from dust and debris.

(3) Check electrical connections and power supply stability.

(4) Lubricate rotating and moving components periodically as per manufacturer guidelines.

(5) Ensure calibration is maintained for accurate torque and angle measurements.

(6) Handle specimens and fixtures carefully to prevent damage to the machine or samples.

在线联系供应商

Other supplier products

| Vacuum Blood Collection Tube Suction Volume Tester | In the medical field, particularly in processes involving blood sample collection, the accuracy of the suction volume of Vacuum Blood Collection Tu... | |

| Flame retardant paper and board burning tester | Technical parameters: 1. Ambient temperature :-10℃——30℃ 2. Relative humidity :{<}85% 3. Power supply voltage and power :220V 10% ... | |

| STD Lithium battery explosion test chamber,Testing Machine | Introduction Lithium battery combustion and explosion experiment chamber is mainly used for thermal runaway combustion and even explosion experime... | |

| Femoral Stem Fatigue Performance Testing Machine | Standard YY/T 0809.4 (China): Specifies fatigue testing protocols for femoral stems in partial/total hip arthroplasty. ISO 7206-4 (International)... | |

| Wet leakage current test system of photovoltaic module | The Wet Leakage Current Test System is designed for high-precision evaluation of insulation resistance and leakage current in photovoltaic modules ... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |