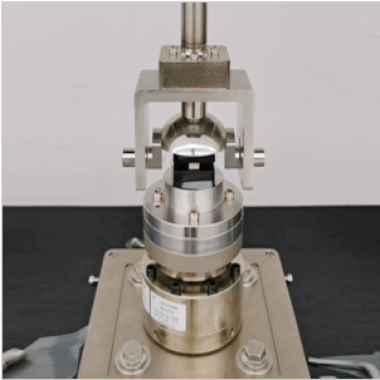

Environmental Stress Cracking Resistance Tester

This instrument is a testing device recommended according to standard requirements. It is a specialized device designed specifically for environmental stress cracking tests of polyethylene plastics. This testing device retains the technical requirements of the original prototype while incorporating structural innovations. It features a sophisticated design and advanced technology.

Applications

1. Plastic and Rubber Material Research and Development: Evaluating the stress crack resistance of new plastic and rubber materials under different environmental conditions, and optimizing material formulations and structures.

2. Product Quality Testing: Conducting quality testing on raw materials, semi-finished products, and finished products to ensure that products meet relevant standards and customer requirements.

3. Component Reliability Testing: Testing components (such as casings and brackets) in electronic and electrical products to identify potential problems in advance and optimize design and manufacturing processes.

4. Packaging Material Evaluation: Evaluating the performance changes of packaging materials under different temperatures, humidity levels, and storage times, providing a basis for selecting suitable packaging materials.

Standards

ASTM D1693: Exclusively designed for bending beam and constant load tests on polyethylene and other thermoplastics.

ISO 22088-3: Configurable for notched specimen testing in aggressive media.

Features

Modular Bath System:

46-position carousel with quick-release glass vessels (250mL capacity).

Dual-circuit heating for rapid temperature equilibration.

Stress Loading System:

Manual or motorized bending fixtures with 0–50N load range.

Laser-aligned specimen grips for consistent strain distribution.

Chemical Management:

Integrated solvent level sensors with low-volume alerts.

Vented enclosure for fume extraction (compatible with external HVA systems).

Data Integrity:

100Hz sampling rate captures crack initiation events.

Wireless data export via Wi-Fi/Bluetooth to LIMS platforms.

Safety Suite:

Leak-proof magnetic drive stirrers.

Emergency solvent dump system with CO₂ fire suppression.

Technical Parameters

| Specification | Details |

|---|---|

| Temperature Range | -10°C to 100°C (water/glycol bath) |

| Temperature Accuracy | ±0.2°C (±0.1°C with calibration kit) |

| Sample Capacity | 460 specimens (46 vessels × 10 samples) |

| Stress Load Range | 0–50N (0.1N resolution) |

| Power Supply | 220V/50Hz (110V/60Hz available) |

| Bath Volume | 60L (expandable to 120L) |

| Dimensions (W×D×H) | 1.200mm × 800mm × 1.850mm |

| Weight | 280 kg (net) |

Accessoriess

Sample Preparation Kit:

ASTM D1693-compliant milling cutters and polishing films.

Prefabricated specimen jigs for 2.75mm bending beams.

Solvent Management:

Explosion-proof storage cabinet for flammable liquids.

Recirculating chiller for sub-ambient testing (-10°C).

Advanced Analytics:

CrackVision™ Software: AI-assisted image analysis for crack length measurement.

LabCloud Pro: Remote monitoring for 100+ concurrent users.

Calibration Bundle:

NIST-traceable temperature/force calibration kit with certificate.

Extended Warranty:

5-year comprehensive coverage for bath and controls.

Test Procedures

1. Set appropriate test parameters

Based on specific requirements, determine appropriate test parameters such as temperature, humidity, stress, or strain to ensure the accuracy and repeatability of the test results.

2. Select suitable test specimens

Select suitable specimen shapes and sizes based on the material characteristics, and ensure that the specimen preparation process meets standard requirements.

3. Data analysis and interpretation

Perform systematic analysis and interpretation of the test results, including indicators such as cracking time, cracking distance, and crack propagation rate, to provide a scientific basis for subsequent applications and decision-making.

4. Safe operation

During operation, pay attention to safety precautions, ensuring that the test platform is stable and avoiding excessive stress or strain that could cause damage to equipment or personnel.

在线联系供应商

Other supplier products

| Wire Torsion and Winding Tester | Product Introduction Metal wire twisting and winding machine is widely used in aerospace, metal material processing, tire manufacturing and other ... | |

| UVA 340 Fluorescent Lamp for UV Aging Chamber | Related Test Equipment -UVAgingChamber Control system: Precise regulation, monitoring of lighting, temperature and humidity, spray and other para... | |

| Falling Sand Abrasion Tester | Standards GB811-2022. GB24429 GB/T 38305 GJB1564A GA/T44. GA293 GA294 GA295 GA296 ASTMD968 ASTMD333 ASTMD1395 ASTMD2205 Main applicati... | |

| Pinhole Tester | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in aluminum foil materials. The following is a detail... | |

| Compression Fatigue Tester | Standard YY/T 0959-2014 (China): Specifies compression fatigue testing protocols for intervertebral fusion devices, including load ratios, frequen... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |