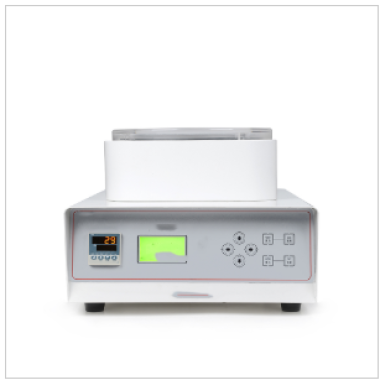

Film Heat Shrinkage Tester

The film heat shrinkage rate tester is a device specifically designed to measure the shrinkage performance of film materials under heating conditions.

Applications

The film heat shrinkage rate tester is mainly used to test the heat shrinkage performance and dimensional stability of various film materials, heat - shrinkable tubes, pharmaceutical PVC sheets, backplanes, etc. in liquid media at multiple temperatures. By precisely measuring the dimensional changes of the film before and after heating and calculating its heat shrinkage rate, the heat shrinkage performance of the material can be evaluated. This performance is directly related to the quality and reliability of products. In the packaging industry, such as in the fields of food, beverages, cosmetics, etc., film materials are widely used for product packaging. The quality of their heat shrinkage performance directly affects the packaging effect and product safety. Through the testing of the film heat shrinkage rate tester, problems that may occur during the heat shrinkage process of materials, such as uneven shrinkage and failure to meet the shrinkage rate standard, can be promptly identified and resolved, thus ensuring the quality of packaging materials.

Standards

ASTM D2732: Standard Test Method for Unrestrained Linear Thermal Shrinkage of Plastic Film and Sheeting

ISO 14616:1997: Plastics — Heat shrinkable films of polyethylene, ethylene copolymers and their mixtures — Determination of shrinkage stress and contraction stress

DIN 53369: Testing of plastic films; determination of the shrinking stress

GB/T 13519-2016:Polyethylene heat-shrinkable film for packaging applications

Features

Digital P.I.D. temperature control technology ensures the preset temperature to be reached rapidly without any fluctuation

The instrument is heated through fluid medium, which could provide the stable test environment

Automatic timer function to efficiently guarantee the accuracy of test data

The instrument is controlled by micro-computer with LCD, PVC operation panel, and menu interface

Standard clamp wire mesh support could make the test done smoothly

Technical Parameters

| Items | Specifications |

| Specimen Size | ≤140 mm x 140 mm |

| Temperature Range | Room temperature ~ 200°C |

| Accuracy | ±0.2°C |

| Power Supply | AC 100-240V 50/60Hz (can be changed to local requirement) |

| Instrument Dimension | 440 mm (W) x 370 mm (D) x 310 mm (H) |

| Net Weight | 24 kg |

Accessoriess

Standard Configurations: Instrument, Micro Printer, 1 Set of Clamp Wire Meshes

Optional Parts: Clamp Wire Mesh and Clamp Wire Mesh Support

Test Procedures

1. Equipment Preparation

Check that the liquid heating medium (e.g., silicone oil) is sufficient. Connect the power supply, turn on the instrument, preheat, and calibrate the temperature control system to ensure the temperature stabilizes within the required test range.

2. Sample Preparation

Cut film samples (e.g., 100x100mm) according to standards such as ASTM D2732. Measure and record the initial length and width dimensions of the sample using calipers.

3. Parameter Settings

Select the compliant standard through the instrument interface and set the test temperature (multiple temperatures are available), holding time, and other test conditions.

4. Test Start

Place the sample flat in the liquid heating medium without constraint, start the test program, and maintain the set temperature and duration to complete the heat shrinkage process.

5. Post-processing and Measurement

Remove the sample and cool it to room temperature. Measure its length and width dimensions again and record the data after shrinkage.

6. Data Calculation

Calculate the shrinkage rate using the formula (Heat Shrinkage Rate = (Initial Size - Shrinkage Size) / Initial Size x 100%6), export the data, and generate a test report.

在线联系供应商

Other supplier products

| Reciprocating Friction and Wear Evaluation Apparatus | Applicable Standards ASTM Standards: Formulated by the American Society for Testing and Materials (ASTM), standards such as ASTM D6079 are used to... | |

| Schopper Abrasion Tester | Standards DIN 53863. Part 2: Abrasion test methods for textile fabrics (rotary abrasion test). GME Standard 60345 & GMW Standard 3283: Indust... | |

| Safety Helmet Lateral Rigidity Tester | The Safety Helmet Lateral Rigidity Tester is a precision instrument designed to evaluate the lateral deformation resistance of helmets under contro... | |

| Diaper Anti-Side Leakage Performance Tester | The Diaper Anti-Side Leakage Performance Tester is designed to accurately measure the liquid loss of nonwoven materials and evaluate the anti-side ... | |

| Camera test light box | Standard ISO 12233: Compliant with SFR (Spatial Frequency Response) testing for lens resolution. IEC 62679: Photometric requirements for video ca... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |