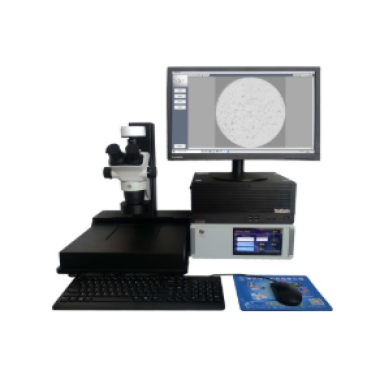

Aluminum Tube Internal Coating Continuity Tester

The Aluminum Tube Internal Coating Continuity Tester is an important device specifically designed for testing the continuity of the internal coating of aluminum tubes.

Applications

The continuity tester for the inner coating of aluminum tubes has extensive application value in multiple fields, and its main uses include: - Quality Inspection: During the production process of aluminum tubes, this tester can be used for the quality inspection of raw materials to ensure that the produced aluminum tubes meet relevant standards and requirements. Through testing, aluminum tubes with coating continuity defects can be promptly identified and removed, preventing unqualified products from entering the market.

- Product R & D: In the product research and development stage, the continuity tester for the inner coating of aluminum tubes can provide important reference information for R & D personnel. By testing aluminum tubes produced under different formulations and processes, R & D personnel can evaluate the continuity and quality of the coating, thereby optimizing the formulation and process to improve product performance and competitiveness.

- Quality Control: During the use of aluminum tubes, this tester can provide an important detection means for quality control departments. Through regular or irregular testing, the continuity and quality changes of the inner coating of aluminum tubes can be monitored, and potential quality problems can be identified and resolved in a timely manner, ensuring product stability and reliability.

Standards

The design and manufacture of the continuity tester for the inner coating of aluminum tubes usually comply with a series of national and international standards to ensure the accuracy and reliability of test results. Among them, common standards include YBB00162002 - 2015 Aluminum Pharmaceutical Soft Tubes, etc. These standards specify in detail the test methods, specimen preparation, test conditions, etc. for the continuity of the inner coating of aluminum tubes, providing a unified standard for the use of the tester.

Features

1. High Specialization: Specifically designed for continuous testing of the inner coating of aluminum tubes, compatible with common aluminum tube specifications of 8-45mm diameter and 35-250mm length, covering most industry application scenarios.

2. High Testing Accuracy: Current measurement accuracy reaches ±0.1mA, accurately identifying minute coating damage and ensuring reliable test results.

3. Flexible Adaptability: The test voltage is adjustable (e.g., DC 5V±0.5V), matching the testing needs of different coating materials and thicknesses.

4. Portable and Easy to Deploy: Compact and lightweight, it can be flexibly deployed in various scenarios such as production sites and laboratories.

5. Multi-Scenario Coverage: Supports full-process applications including raw material quality inspection, new product R&D assistance, and in-use product quality control, contributing to quality management.

Technical Parameters

| Technical Parameter | Specification |

|---|---|

| Testing Range | Applicable to aluminum tubes with a diameter between 8 and 45mm and a tube length between 35 and 250mm (covers most common aluminum tube specifications, ensuring wide applicability). |

| Testing Accuracy | Usually high; e.g., current measurement accuracy can reach ±0.1mA. High-precision measurements support quality control and product R&D. |

| Testing Voltage | Usually adjustable within a certain range, such as DC 5V±0.5V. Adjusting voltage meets testing requirements of different coating materials and thicknesses. |

| Input Voltage and Power Supply | Input voltage: AC 220V 50Hz (standard voltage in most regions); equipped with a stable power supply system to ensure voltage stability and data accuracy. |

| Appearance Dimensions and Weight | Usually compact and portable (varies by model/brand), enabling use in different production sites and laboratories. |

| Working Environment | Working temperature: 23℃±2℃; relative humidity: not exceeding 80% (without condensation). Ensures normal operation and test result accuracy. |

Accessoriess

Multi-size aluminum tube clamps: Adaptable to aluminum tubes with diameters of 8-45mm and lengths of 35-250mm, ensuring stable sample clamping.

Standard calibration aluminum tubes: Aluminum tube samples with known coating conditions, used for periodic accuracy calibration of the equipment.

Internal coating electrode probe: The detection component that contacts the inner coating of the aluminum tube, ensuring stable transmission of electrical signals.

Data transmission cable: Connects the equipment to a computer, enabling the export and storage of test data.

Probe cleaning brush: Cleans the surface of the electrode probe to prevent coating residue from affecting detection accuracy.

Test Procedures

1. Equipment Preparation

Connect to AC 220V 50Hz power supply. Confirm the working environment (23℃±2℃, humidity ≤80%, non-condensing). After powering on and preheating, calibrate the equipment using a standard calibration aluminum tube.

2. Sample Preparation

Select the aluminum tube to be tested and clean its inner surface (remove impurities). Confirm that the dimensions are within the equipment's testing range.

3. Parameter Setting

Set the test voltage (e.g., DC 5V±0.5V) through the equipment interface, matching the coating material and thickness.

4. Sample Clamping

Fix the aluminum tube in the corresponding specification clamp, ensuring full contact between the electrode probe and the inner coating.

5. Start Testing

Run the testing program. The equipment automatically detects the electrical continuity of the coating and records the data.

6. Result Determination

Determine whether there are defects such as discontinuities or breaks in the coating based on the current data.

7. Post-processing

Remove the sample, clean the electrode probe, export the data, and generate a test report.

在线联系供应商

Other supplier products

| Carbon Black Content Tester | Standard GB 13021-1991: Determination of carbon black content in polyethylene compounds. GB/T 2951.41-2008: Test method for carbon black and ash ... | |

| Cleanliness Analyzing System | Production: The cleanliness analysis system fully complies with the requirements of standards such as VDA19.1 - 2015. ISO16232. ISO4406. ISO4407. ... | |

| Film impact Tester (Gardner) | The Film Impact Tester (Gardner) is designed to evaluate the impact resistance of coatings and paint films. It determines the degree of damage such... | |

| Reciprocating Friction and Wear Evaluation Apparatus | Applicable Standards ASTM Standards: Formulated by the American Society for Testing and Materials (ASTM), standards such as ASTM D6079 are used to... | |

| Waterproof socks testing machine | The Waterproof Socks Testing Machine is designed to evaluate the water resistance and waterproof performance of socks, shoes, and shoe linings made... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |