Glass Bottle Internal Pressure Resistance Tester

The internal pressure resistance tester for glass bottles is a device specifically used to test the internal pressure - resistance performance of glass bottles.

Applications

The internal pressure resistance tester for glass bottles is mainly used to evaluate the ability of glass bottles to withstand pressure under different pressure conditions. Through testing, we can determine whether glass bottles can withstand a certain internal pressure without breaking or deforming during the processes of filling, transportation, and use. This device is widely applied in industries such as beer brewing, pharmaceutical production, and food packaging, and is of great significance for ensuring product quality and consumer safety. In the beer - brewing field, the internal pressure resistance tester for glass bottles is used to inspect the internal pressure - resistance ability of beer bottles and other alcohol - beverage packaging bottles, ensuring that they will not break due to pressure changes during filling, transportation, and use. In the pharmaceutical production process, this device is used to test the internal pressure resistance of pharmaceutical packaging bottles such as antibiotic vials and infusion bottles, safeguarding the stability and safety of drugs during storage and transportation. In addition, in the food - packaging field, various beverage bottles such as carbonated beverage bottles and juice bottles also need to undergo internal pressure - resistance testing using this device.

Standards

The design and manufacture of the internal pressure resistance tester for glass bottles comply with a series of national and international standards to ensure the accuracy and reliability of test results. Among the more common standards are GB/T 4546 - 2008 Test Method for Internal Pressure Resistance of Glass Containers and ISO 7458:2004 Test Method for Internal Pressure Resistance of Glass Containers. These standards specify in detail the test methods for the internal pressure resistance of glass bottles, specimen preparation, test conditions, etc., providing a unified standard for the use of the tester.

Features

• Large color LCD display showing test results, including each measurement and statistical value;

• Touchscreen control, clear and intuitive, easy to operate;

• High-speed processing chip, significantly improving operating speed;

• Adjustable test space, suitable for a wide range of products;

• Capable of constant pressure holding tests, pressurized but not held pressure tests, and burst tests;

• Equipped with a micro printer for quick printing of each measurement result, statistical values, and average values;

• The instrument can store multiple sets of data, with 10 measurements per set;

• Equipped with testing software for unlimited storage and printing;

• No complex hydraulic system, reducing leakage rate and facilitating maintenance;

• The system program has an ISP online upgrade function, providing personalized services.

Technical Parameters

| Technical Parameter | Specification |

|---|---|

| Testing Pressure Range | Usually it can reach 0 - 6MPa or higher (specific range depends on equipment model and testing requirements); covers internal pressure-resistance testing needs of most glass bottles. |

| Display Accuracy | Generally 0.001MPa or higher; enables precise display of pressure changes during the testing process. |

| Pressurizing Medium | Usually water (ensures no additional pressure impact on glass bottles; also convenient for controlling and monitoring pressure changes). |

| Testing Speed | Relatively fast; testing time per bottle ranges from a few seconds to a dozen seconds (depends on equipment model, testing pressure, and specimen specifications); helps improve testing efficiency and productivity. |

| Overall Error | Usually less than 0.5%FS (full-scale error); ensures the accuracy and reliability of test results. |

| Working Environment | Needs to be used in a certain environment: temperature range of 5 - 40℃ (varies by equipment model), relative humidity not exceeding a certain value; helps maintain equipment stability and extend its service life. |

| Safety Performance | Equipped with safety features (e.g., leak-protection control circuits) to ensure operator safety; also has automatic fault detection and common fault prompting functions, facilitating prompt problem identification and resolution. |

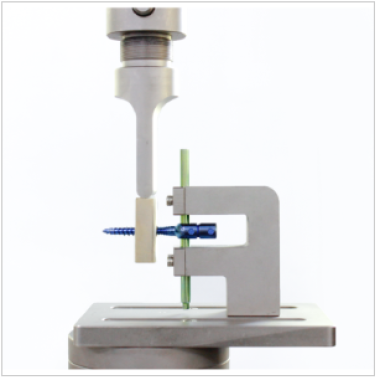

Accessoriess

Standard configuration: Glass bottle internal pressure testing machine main unit, micro printer, fixtures

Optional accessories: Testing software, communication cable

Test Procedures

Method A: Constant Internal Pressure Test

Method A tests the pressure resistance of a glass container by applying a constant internal pressure over a predetermined time. Its core requirements include:

Test Conditions: Tap water is used as the test medium. The sample must be filled with water at room temperature, within ±5°C of room temperature, to avoid additional pressure interference.

Equipment Requirements: The testing equipment must be capable of clamping the bottle mouth and suspending the sample, and equipped with an elastic sealing ring to ensure the sealing of the pressurized medium. The pressurization device must initially pressurize at a rate of 1.0 MPa/s ± 0.2 MPa/s and maintain a constant pressure.

Test Procedure:

Passability Test: Increase the internal pressure to the predetermined value, maintain it for 60 seconds ± 2 seconds, and observe whether the sample remains intact.

Incremental Pressure Test: Based on the passability test, gradually increase the pressure in increments of 0.1 MPa or 0.2 MPa until the sample breakage rate reaches 50% or 100%.

Method B: Incremental Internal Pressure Test

Method B determines the ultimate pressure resistance value by increasing the internal pressure at a constant rate until the sample ruptures. The standard specifies clear requirements for pressurization rate and test environment to ensure the accuracy and repeatability of test results.

Sampling and Precautions

The standard emphasizes that test samples must be glass containers that have not undergone other mechanical or thermal property tests to avoid affecting the internal pressure resistance test results. The sampling quantity should comply with regulations to ensure the representativeness and statistical significance of the test.

在线联系供应商

Other supplier products

| Bending Tester STD- FB2 - S | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rigid Plastics) SAE J2748 (Automotive Composite Flex... | |

| Aluminum Tube Internal Coating Continuity Tester | The Aluminum Tube Internal Coating Continuity Tester is an important device specifically designed for testing the continuity of the internal coatin... | |

| Prefilled Syringe Plunger Force Tester | The Prefilled Syringe Plunger Force Tester is widely used in the medical device industry, mainly for testing the push - force performance of prefil... | |

| Rapid screening Calorimeter | The rapid - screening calorimeter is a professional calorimetric instrument for the quick assessment of reaction thermal hazards. It supports multi... | |

| Bone Plates Static Four - point Bending Tester | Standard YY/T 0342-2022: Chinese standard specifying methods for determining bending strength and equivalent bending stiffness of straight and pre... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |