Bubble Leak Tester

The Bubble Leak Tester utilizes a positive pressure testing principle and is suitable for the quantitative measurement of sealing strength, heat seal quality, burst pressure, and leakage performance of various sealed packages; it can also be used for the quantitative measurement of the sealing performance of various plastic tamper-evident caps, inflatable packaging, ointment tubes, and medical packaging. Simultaneously, it can perform analysis and testing of various bottle body sealing properties, compressive strength, and burst resistance.

Applications

Medical Device Packaging Inspection:The Gross Leak Tester can be used for the sealing performance testing of various medical device packages, such as trays and combined packages, ensuring that the packages will not leak and cause product contamination during transportation and storage. The instrument can also be used to detect key indicators such as the pressure - resistance of the package, heat - sealing quality, and the bursting pressure of the entire package. Bottle Cap Sealing Performance Testing: It is suitable for the sealing performance testing of various plastic anti - theft bottle caps, ensuring that the bottle caps can effectively prevent liquid leakage after being sealed. Bottle Body Sealing and Compression Resistance Testing: It can be used for the testing of the sealing, compression resistance, and durability of various bottle bodies, providing quality assurance for bottle body design and production. Soft Tube Testing: It is suitable for the sealing performance testing of soft tube packages such as various toiletries, medicinal ointments, and food packaging.

Other Applications: It can also be used for the sealing performance testing of aerosol valves and the pressure - resistance testing of blister packages.

Standards

YY/T 0681.5 - 2010:Test methods for sterile medical device package - Part 5: Detecting gross leaks in medical packaging by internal pressurization (bubble test)

Features

• Embedded high-speed microcomputer chip control and a simple and efficient human-machine interface provide users with a comfortable and smooth operating experience.

• 7-inch high-definition color LCD screen displays test data and curves in real time.

• Supports expansion suppression and non-suppression testing.

• Overvoltage safety protection, power-off memory, and other safety features ensure system stability during testing.

• English and Chinese interfaces can be switched freely.

• Equipped with a standard RS232 communication port for convenient external connection and data transmission between the system and a computer.

• Energy-saving and environmentally friendly design, aesthetically pleasing appearance, and ultra-low power consumption power supply meet national energy-saving and environmental protection requirements.

Technical Parameters

| Parameter | Specification |

|---|---|

| Testing Range | Suitable for the gross leak testing under internal pressure of various packages, and the testing pressure range can be customized according to requirements. |

| Testing Principle | Based on the positive-pressure testing principle, a certain pressure is applied to the inside of the package, and it is determined whether there is a gross leak by observing whether bubbles are generated on the outside. |

| Automated Control | Equipped with a PLC industrial control program, which can accurately control the pressure and time, and automatically complete the experiment after setting the test pressure and time. |

| Ease of Operation | With a touch-screen operation interface, it is highly user-friendly and simple to operate. |

| Testing Accuracy | The testing error is usually within ±1%, ensuring the accuracy of test results. |

| Constant Pressure Time | Can be set through the touch-screen, with a range of 1 - 9999 seconds. |

| Air Source Interface | Usually equipped with a Φ6mm polyurethane tube and an 8mm interface for easy connection to the air source. |

| External Dimensions | May vary depending on the model but are usually compact; e.g., some models: 420mm(L)×290mm(W)×280mm(H) |

Accessoriess

StandardAccessories:Usually includes the main unit, a puncture device, a test container, etc.

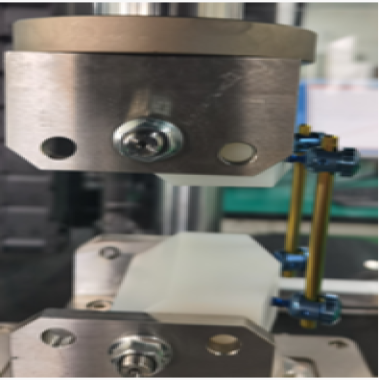

Optional Accessories:Non-standard devices such as a standard test rack, a three-side testing fixture, a constraint plate testing fixture, and an anti-theft bottle cap removal fixture (selected as needed).

Test Procedures

When selecting a gross leak tester, attention should be paid to whether it supports the full process of YY/T 0681.5-2010. covers a pressure range of 0~5kPa or higher, and has adaptability to various fixtures. Routine maintenance includes regularly calibrating the sensors, cleaning the water tank, and checking the seals to ensure long-term stable operation.

在线联系供应商

Other supplier products

| Catheter Balloon Inflation Diameter Tester | The Catheter Balloon Inflation Diameter Tester is a precision device widely used in the medical field, specifically designed to measure and test th... | |

| Spinal Pedicle Screw-Rod System Compressive Fatigue Testing Machine | Standard YY/T 0857-2011 (China): Specifies compression fatigue testing protocols for spinal pedicle screw-rod systems, including load ratios, freq... | |

| Reciprocating Friction and Wear Testing Machine | Applicable Standards ASTM Standards: Formulated by the American Society for Testing and Materials (ASTM), standards such as ASTM D6079 are used to... | |

| 5kn 10kn 20kn 30kn 50kn 100kn Universal Material Tensile Tester | Applicable Industries Fast Delivery Parts Of Universal Testing Machine,Tensile Compression Testing Machine,Universal Testing Equipment can test va... | |

| 20L Spherical Explosion Tester | Product Description: 20L Spherical Explosion Tester is characterized by accurate test data and ease of use. Its through the compressed air will be... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |