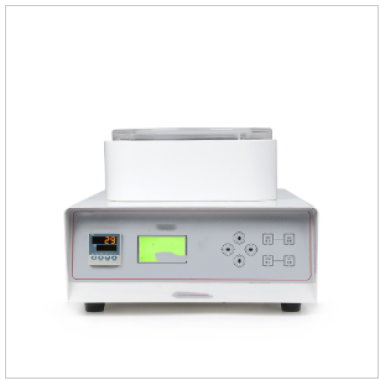

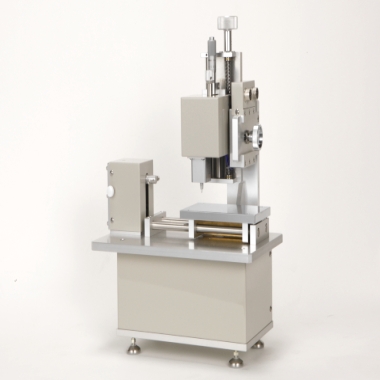

Catheter Hydraulic Leakage Tester

The Catheter Hydraulic Leakage Tester is a testing instrument specifically developed and manufactured for leak detection and quality assessment of various products such as plastic composite bags, hoses, packaging bags, boxes, and pipelines. It utilizes the most advanced dual testing principles of positive and negative pressure methods, collecting data in real-time through high-precision pressure sensors, thereby effectively ensuring the accuracy and reliability of the test results. In addition, the instrument offers multiple independent test modes for users to choose from, meeting diverse testing needs.

Applications

The catheter hydrostatic pressure resistance and leakage tester is a device specifically designed to evaluate the sealing performance of catheters in a hydraulic environment. Its main uses include: Ensuring Catheter Safety: Through testing, it ensures that catheters have good sealing performance under various usage conditions, preventing liquid leakage and thus safeguarding the safety of patients. Improving Product Quality: It provides data support for medical device manufacturers, helping them to improve the design and manufacturing processes of catheters, and enhancing the quality and reliability of products. Promoting Technological Advancement: The application of the tester promotes technological progress and development in the medical field, and provides a powerful testing tool for the research and development of new - type catheters.

Standards

GB/T 15812.1: Disposable sterile catheters - Part 1: General requirements

Features

1. Large-Sized LCD Touchscreen Display: The instrument is equipped with a large-sized LCD touchscreen display, allowing users to intuitively and conveniently view real-time displays of test curves. In addition, the display screen features multiple shortcut buttons for easy test operation.

2. Dual Positive and Negative Pressure Testing Modes: The instrument utilizes both positive and negative pressure testing modes, comprehensively covering various types of leakage problems. The positive pressure method detects leaks or ruptures by filling the sample with a certain pressure of gas; the negative pressure method detects leaks by vacuuming the sample or sealed container.

3. High-Precision Pressure Sensor: The instrument uses a high-precision pressure sensor, capable of accurately capturing subtle changes in the sample under different pressure conditions, thus ensuring the accuracy and reliability of test results.

4. Diverse Testing Modes: In addition to the two basic testing modes mentioned above, the instrument also provides several independent testing modes, such as burst strength testing, gross leak testing, bottle cap seal testing, etc., to meet the testing needs of users in different scenarios.

5. Intelligent Operation: The instrument adopts an intelligent operation method; users can complete the testing process by simply pressing the corresponding buttons. The instrument also features various intelligent operation modes such as automatic pressure maintenance, automatic bursting, and rapid leak detection, which users can freely select according to their actual needs.

6. Automatic Test Report Printing: To facilitate users in recording and analyzing test results, the instrument has a built-in miniature printer that can automatically print detailed test reports.

7. Automatic Vacuum Maintenance and Back-Flushing Discharge Function: The instrument features automatic vacuum maintenance and automatic back-flushing discharge after testing, making the entire testing process more automated and efficient.

8. Automatic Constant Pressure Gas Supply Function: The instrument has an automatic constant pressure gas supply function, ensuring fully automatic testing under set vacuum conditions, further improving testing efficiency and accuracy.

9. GMP Permission Management Function: The instrument complies with relevant GMP (Good Manufacturing Practice) regulations and has strict permission management functions, ensuring the security and confidentiality of test data.

Technical Parameters

| Parameter | Specification |

|---|---|

| Test Flow | Usually 30L/min, with an error ≤ ±5%; ensures stable and accurate flow during testing |

| Pressure Range | Generally 0 - 500KPa, with a resolution of 0.01KPa and an error ≤ ±1%; covers the pressure range most catheters withstand in actual use (ensures test comprehensiveness) |

| Measurement System Holding Time | Usually 1 minute (configurable); maintains a stable measurement environment during testing (improves test accuracy) |

| Test Duration | Generally 1 second - 99.9 minutes, with an error ≤ ±1 second; allows flexible setting of test time according to actual needs (ensures test adequacy and effectiveness) |

| Applicable Catheter Types | Applicable to various medical device products: infusion sets, blood transfusion sets, infusion needles, filters, pipelines, catheters, quick-connect fittings, etc. (meets testing needs of different products) |

Accessoriess

Main unit, hydraulic tank, miniature printer

Test Procedures

1. Pre-test preparation

Check the equipment power supply and hydraulic system sealing, and prepare the test tubing and adapter fittings;

2. Sample installation

Connect the tubing to the equipment's hydraulic circuit using a special connector, ensuring a sealed connection;

3. Parameter setting

Select the corresponding standard (e.g., GB/T 15812.1) via the touchscreen, and set parameters such as test flow rate, pressure range, and pressure holding time;

4. Start testing

The equipment automatically fills with fluid and pressurizes, maintaining the set parameters and monitoring for leaks;

5. Process monitoring

Observe pressure changes to confirm whether there are any leakage abnormalities;

6. Completion

After the equipment depressurizes, remove the tubing, record the results, and clean the pipeline.

在线联系供应商

Other supplier products

| Fiber Blend Ratio meter | Product Introduction: It is used to measure the resistance value with a certain density under a certain geometry, and then converts it into the sp... | |

| Film Heat Shrinkage Tester | The film heat shrinkage rate tester is a device specifically designed to measure the shrinkage performance of film materials under heating conditio... | |

| Sweating Thermal Manikin丨Sweating Thermal Manikin tester | Standards compliant ISO 15831:2004(E) Clothing-Physiological effects -Measurement of ASTM F 1291-04Standard Test Method for Measuring the Thermal... | |

| UVA 340 Fluorescent Lamp for UV Aging Chamber | Related Test Equipment -UVAgingChamber Control system: Precise regulation, monitoring of lighting, temperature and humidity, spray and other para... | |

| Resistance Tester for Molten Metal Droplet (Splash) Impact Performance | Performance and Standards: This resistance tester for molten metal droplet (splash) impact performance is developed in accordance with testing sta... |

Same products

| Gas Oxidizing Property Tester | 卖方: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | 卖方: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | 卖方: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | 卖方: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |