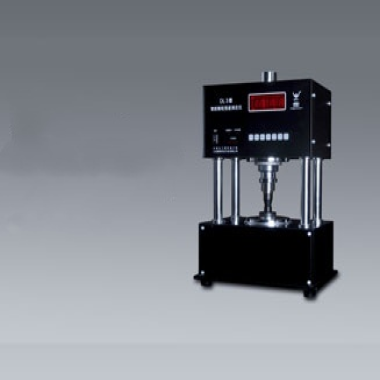

Particle Strength Tester

The Particle Strength Tester is a high-precision instrument designed to measure the mechanical strength of individual particles, granules, and catalyst carriers. It provides versatile testing capabilities—including compression, tension, shear, and indentation—to evaluate particle durability and resistance under controlled conditions. Equipped with intelligent automation, environmental control options, and advanced data acquisition, it is suitable for laboratories, quality control, and research & development in chemical, pharmaceutical, and material science industries.

Application

(1) Testing single-pellet pressure resistance of catalysts and catalyst carriers

(2) Measuring radial crush strength of extruded catalyst and granular particles

(3) Evaluating mechanical durability of pharmaceutical granules, food pellets, and ceramic particles

(4) Quality control of particle materials in chemical, pharmaceutical, and materials manufacturing

(5) Research and development for improving particle formulations and process optimization

(6) Non-destructive internal defect inspection via ultrasonic imaging

Standards

(1) ASTM D4179 — Standard Test Method for Single-Pellet Pressure Resistance of Catalysts and Catalyst Carriers

(2) ASTM D6175 — Standard Test Method for Radial Crush Strength of Extruded Catalyst and Catalyst Carrier Particles

(3) ISO 9773 — Methods for Testing Catalysts: Radial Crush Strength

(4) ISO 13320 — Particle size analysis reference (applicable for particle testing)

(5) ISO 16105 — Determination of mechanical properties of catalysts and adsorbents

(6) USP <616> — Pharmaceutical granule strength assessment (for pharmaceutical applications)

Features

(1) Unrivaled Precision: Sub-micron displacement resolution (0.01 μm) and sub-Newton force detection (0.001 N) for fragile particles

(2) Universal Applicability: Tests particles 0.1–50 mm, including spherical, cylindrical, and irregular shapes

(3) Multi-Mode Testing: Supports compression, tension, shear, and indentation on one platform

(4) Intelligent Automation: AI-driven load application with auto-centering fixture to prevent sample damage

(5) User-Friendly Workflow: 10.1” HD touchscreen with gesture control and one-click testing for ASTM/ISO protocols

(6) Data Integrity & Analytics: Blockchain-secured data storage, cloud connectivity, and AI-driven failure prediction

(7) Environmental Control: Optional temperature (-40°C to 200°C) and humidity (10%–95% RH) chamber compatibility

(8) Non-Destructive Testing Option: Ultrasonic imaging module for visualizing internal cracks without sample destruction

(9) Dynamic Force Profiling: Programmable force ramps with sinusoidal, triangular, or custom waveforms

(10) Safety Features: Laser-based emergency stop system with safety curtain

Parameters

| Parameter | Specification |

|---|---|

| Force Range | 0.001 N – 5,000 N (500 kgf) |

| Force Accuracy | ±0.1% of reading (1–5,000 N) |

| Displacement Resolution | 0.01 μm |

| Testing Speed | 0.001–1,000 mm/min (adjustable) |

| Return Speed | Up to 2,000 mm/min |

| Connectivity | USB 3.1, Ethernet, Wi-Fi 6, Bluetooth 5.0 |

| Power Consumption | 600 W (max), 50 W (idle) |

| Dimensions | 550 mm (W) × 480 mm (D) × 720 mm (H) |

| Weight | 75 kg (net) / 90 kg (gross) |

Accessories

(1) Testing Fixture Kit: Compression platens (2/5/10 mm), tensile grips (0.5–50 mm), shear blade set (V-notch & flat)

(2) Software Suite: ParticleAnalyst Pro license, 6-month AI-driven failure prediction module access

(3) Calibration & Safety: NIST-traceable weights (1–500 g), emergency stop pendant with magnetic dock

(4) Portability & Storage: Shockproof carrying case with foam inserts, dust cover, anti-vibration pads

(5) Documentation: Quick-start guide (printed & digital), compliance certificates for ASTM/ISO standards

Test Procedures

Select the appropriate testing mode (compression, tension, shear, or indentation).

Mount the particle using the auto-centering fixture or relevant grip/fixture.

Set test parameters: force range, displacement, speed, and number of cycles if applicable.

If required, activate environmental chamber for temperature and humidity control.

Start the test; AI-controlled system automatically adjusts load to prevent sample damage.

Monitor real-time data via the touchscreen interface.

Save results to blockchain-secured storage and/or cloud platform.

For non-destructive testing, activate ultrasonic imaging module to inspect internal structure.

Maintenance Information

(1) Clean fixtures, grips, and platen surfaces after each test to prevent contamination.

(2) Periodically calibrate force sensors and displacement encoders using NIST-traceable weights.

(3) Inspect electrical connections and safety systems (laser curtain, emergency stop) for proper function.

(4) Maintain environmental chamber (if installed) by checking humidity and temperature sensors.

(5) Keep the instrument in a clean, dry, and vibration-free environment to ensure long-term accuracy.

(6) Update software and AI modules regularly to ensure compatibility with new ASTM/ISO standards.

在线联系供应商

Other supplier products

| Reciprocating Friction and Wear Evaluation Apparatus | Applicable Standards ASTM Standards: Formulated by the American Society for Testing and Materials (ASTM), standards such as ASTM D6079 are used to... | |

| Particle Strength Tester | Standard ASTM D4179: Standard Test Method for Single-Pellet Pressure Resistance of Catalysts and Catalyst Carriers ASTM D6175: Standard Test Me... | |

| Contact heating and cooling test device | The sensation of coldness or warmth when skin touches a fabric is referred to as the "coldness and warmth feeling." The feeling of coldness or warm... | |

| Liquid Sustained Combustion Tester | Product Introduction This product complies with "Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria" 32.5.2 Test L... | |

| Flip Phone Durability Tester | Product Introduction: Mobile clamshell testing machine is a special equipment for mobile clamshell fatigue test. Its structure design is reason... |

Same products

| Falling Sand Abrasion Test machine | 卖方: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | 卖方: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | 卖方: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | 卖方: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |