High temperature vacum friction & wear tester

The working principle of a high-temperature vacuum friction and wear testing machine is to simulate the friction and wear behavior of materials under actual working conditions by controlling and changing parameters such as load, rotation speed, and time. The testing machine has multi-parameter control capabilities through flexible setting of parameters such as load, motion mode, temperature, and medium, thereby effectively reproducing the coupling effect of mechanics and the environment.

Application

High temperature vacuum friction and wear testing machine is mainly used to study the friction and wear characteristics of materials in high temperature and vacuum environment. Its exquisite design and comprehensive functions can simulate a variety of practical conditions and provide reliable experimental data for researchers. Specifically, the main uses of the testing machine include:

Materials science research: By simulating the friction and wear process under high temperature vacuum environment, we can deeply explore the friction and wear mechanism of materials, and provide experimental support for theoretical research and application development of materials science.

Aerospace applications: When spacecraft operate in high temperature and vacuum environments, the friction and wear properties of their components are critical. The testing machine can be used to evaluate the high temperature vacuum friction and wear resistance of aerospace materials, and provide a basis for the selection and design of components.

Automotive industry applications: Components such as automotive engines work at high temperatures and in specific atmospheres, and their friction and wear performance directly affects the performance and life of the vehicle. The testing machine can be used to evaluate the wear resistance of auto parts in high temperature vacuum environment, and provide experimental data for improving and optimizing auto parts.

Other industrial applications: In metallurgy, chemical industry, energy and other industrial fields, there are also friction and wear problems in high temperature and vacuum environment. The testing machine can be used to evaluate the high-temperature vacuum friction and wear resistance of materials used in these fields, providing strong support for industrial production and quality control.

Standards:

When conducting high-temperature vacuum friction and wear tests, it is usually necessary to follow certain standards and specifications. Here are some common applicable standards:

ASTM Standards: Relevant standards developed by the American Society for Materials and Testing (ASTM) may contain specific methods and requirements for high-temperature vacuum friction and wear tests. These standards specify the loading method, test temperature, vacuum degree, data recording and other parameters and requirements during the test process.

1SO standard: The International Organization for Standardization (1SO) may also have developed standards related to high-temperature vacuum friction and wear tests. These standards first ensure the accuracy and comparability of test results, and provide a uniform basis for international scientific research cooperation and industrial exchanges.

Other industry standards or enterprise standards: In addition to the general standards mentioned above, different industries or enterprises may also develop specific testing standards. These standards may have specific requirements for specific material types, test conditions or treatment of test results.

It is important to note that different standards and specifications may have different requirements for different types of materials and test environments. Therefore, when conducting high-temperature vacuum friction and wear tests, it should be ensured that the selected standards are consistent with the test purpose and requirements.

Feature

High-Temperature Environment Simulation: Simulates actual working conditions for testing by controlling and changing parameters such as load, rotation speed, and time.

Multi-Parameter Control: Simulates the friction and wear behavior of materials under actual working conditions by flexibly setting parameters such as load, motion mode, temperature, and medium.

Real-Time Monitoring: The equipment can monitor indicators such as friction force, wear amount, and temperature in real time and output key data.

Multiple Friction Pair Forms: Supports multiple friction pair forms (such as ball-disc, ring-block) and motion modes (rotation, reciprocating).

Parameters:

|

Parameters |

Unit |

min |

max |

note |

|

|

Pin/Ball Diameter |

mm |

3 |

12 |

Round or square pins |

|

|

Wear track diameter |

mm |

15 |

70 |

Disk diameter 100 mm |

|

|

Rotational speed of the disk |

rpm |

1 |

2000 |

0.1rpm Minimum Count |

|

|

Positive load |

N |

0 |

60 |

50 mN Minimum Count |

|

|

friction |

N |

0 |

20 |

5mN Minimum Count |

|

|

temperature |

℃ |

indoor temperature |

800 |

1°C Minimum Count |

|

|

Wear test range |

um |

0 |

2000 |

0.1μm Minimum Count |

|

|

disk vibration |

Stroke Vibration |

degrees |

0 |

0 |

1 degree minimum count |

|

angular frequency |

Hz |

0.1 |

5 |

||

|

Preset Timer |

Hr/Min/ ec |

99/59/59 |

|||

|

Battery |

V/kVA/Ph/Hz |

230/10/1/50 |

|||

Accessoriess

Vacuum system related components

Core components for friction and wear testing

Temperature control module components

Drive and transmission components

Data acquisition and control systems, etc.

Test Procedures

Before operating a friction and wear testing machine, users should familiarize themselves with the basic structure and functions of the equipment. The testing machine typically consists of a main unit, loading device, friction pairs, measurement system, and control system. Before conducting the experiment, the equipment must be inspected and debugged, including confirming that the power connection is normal, all components are undamaged, and the lubrication system is in good condition. Ensuring the equipment is in optimal working condition is fundamental for accurate testing.

Sample preparation is also crucial before the experiment begins. The shape, size, and surface treatment of the sample should meet standard requirements, and it must be cleaned before testing to remove surface contaminants and ensure the validity of the experimental results. The sample must be securely installed to prevent displacement during the test.

Setting test parameters is an important step in friction and wear testing. These include load, speed, temperature, and test time, all of which should be adjusted according to the specific test standards and material properties. Reasonable parameter settings can simulate actual working conditions, thereby obtaining more representative test data.

During the test, real-time monitoring of data changes is essential. Users should regularly check parameters such as the coefficient of friction and wear, and record the data for subsequent analysis. After the test, the equipment should be cleaned and maintained promptly to ensure its long-term stability and reliability. Data analysis and report writing are essential components of friction and wear testing. Based on the test results, users should use statistical methods to analyze the data, generate an experimental report, and evaluate the material properties. A proper interpretation of the test results helps in making informed decisions regarding material selection and application.

在线联系供应商

Other supplier products

| Deval abrasion testing machine | The Deval Abrasion Testing Machine is designed to measure the wear resistance of stones and aggregates under dry or wet conditions. It provides rel... | |

| Carpet Static Load Tester | Instrument Description When furniture is moved, imprints are often left at the position of its feet. These imprints will disappear only when the c... | |

| Salt Spray Testing Machine | Meet the standard: GB/T2423.17 Product Introduction: This type of salt spray test chamber is one of the artificial climate environmental “... | |

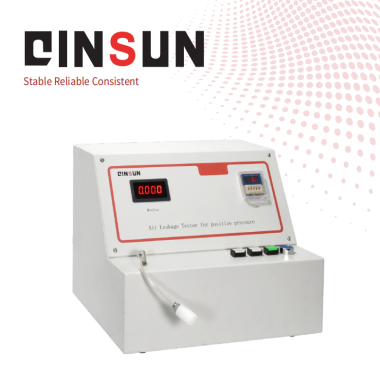

| Infusion Apparatus Leakage Positive Pressure Tester | The M102 Infusion Apparatus Leakage Positive Pressure Tester is designed to evaluate the airtightness and sealing performance of medical injection ... | |

| Elastic Tape Fatigue Tester | Standards: SATRA TM103 Application: Elastic Tape Fatigue Testing Machineis used to determine its repeatedly extend performance under maximum ext... |

Same products

| Falling Sand Abrasion Test machine | 卖方: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | 卖方: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | 卖方: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | 卖方: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |