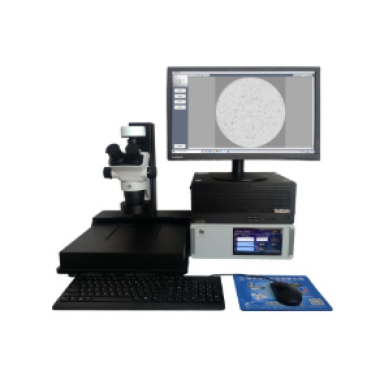

Model Coin-cell Swelling System

The Model Coin-Cell Swelling System is designed for in-situ measurement of thickness and volume changes of coin-type lithium-ion cells during charge and discharge processes. The system adopts high-precision non-contact laser displacement sensing to capture micron-level swelling behavior under controlled temperature and pressure conditions. It provides reliable and repeatable data for material screening, structural optimization, and safety evaluation of coin-cell batteries.

Application

(1) In-situ swelling and thickness change measurement of coin-type lithium-ion cells during cycling.

(2) Expansion behavior evaluation of standard coin-cell formats including 2032, 2025, and 2016.

(3) Screening and comparison of electrode materials such as graphite, silicon-based anodes, and solid-state electrolytes.

(4) Mechanical stability and fatigue analysis of electrode stacks under pressure cycling.

(5) Thermal–mechanical coupling analysis under high-temperature and low-temperature environments.

(6) Safety and reliability assessment during fast charge, overcharge, and abuse testing.

(7) R&D validation and quality consistency evaluation for laboratory-scale battery development.

Standards

(1) ASTM E83 – Standard Test Method for Verification of Linear Displacement Measuring Systems.

(2) ISO 12417-1 – Mechanical Testing of Metals – Dilation Test (reference method).

(3) IEC 62660-2 – Secondary Lithium-Ion Cells – Reliability and Abuse Testing.

(4) DIN 51221 – Testing of Adhesives – Determination of Tensile Shear Strength (reference for deformation testing).

(5) CE Certification – Conformité Européenne.

Features

(1) Micron-level non-contact laser displacement measurement with high repeatability.

(2) High-resolution detection of subtle thickness and volume changes in coin cells.

(3) Multi-environment testing capability with integrated temperature chamber.

(4) Dynamic pressure loading for electrode stack fatigue and structural response analysis.

(5) Eight-channel parallel testing to improve screening efficiency and data consistency.

(6) Laser-guided positioning system for precise coin-cell alignment.

(7) Automatic thermal drift compensation during long-term cycling tests.

(8) Dual redundant safety protection with emergency stop function.

(9) Glovebox-compatible design for oxygen- and moisture-sensitive chemistries.

Parameters

| Parameter | Specification |

|---|---|

| Displacement Range | ±500 μm (linear), ±0.5° (angular) |

| Linear Measurement Accuracy | ±0.05 μm |

| Angular Measurement Accuracy | ±0.005° |

| Displacement Resolution | 0.1 μm |

| Temperature Range | -20°C to 150°C |

| Temperature Ramp Rate | ≤ 2°C/min |

| Pressure Range | 0–10 bar |

| Test Channels | 8 channels |

| Data Acquisition Rate | 10,000 points/s/channel |

| Power Supply | AC 100–240 V, 50/60 Hz |

| Dimensions (W×D×H) | 400 × 350 × 600 mm |

| Weight | 65 kg (net) / 80 kg (gross) |

Accessories

(1) Non-magnetic coin-cell holders for 2032, 2025, and 2016 formats.

(2) Laser displacement sensor modules.

(3) Temperature-controlled environmental chamber.

(4) Pressure loading and control unit.

(5) Data acquisition and analysis software.

(6) NIST-traceable displacement calibration standards (100 μm, 500 μm).

(7) Gas purification cartridge for inert atmosphere operation.

(8) Humidity sensor with data logging function.

Test Procedures

(1) Install the coin cell into the designated non-magnetic holder.

(2) Align the coin cell using the laser-guided positioning system.

(3) Set temperature, pressure, and cycling parameters according to test requirements.

(4) Initiate the charge/discharge process and start in-situ displacement monitoring.

(5) Record real-time thickness and swelling data throughout the test cycle.

(6) Export test data for further analysis, comparison, and reporting.

Maintenance Information

(1) Periodically calibrate the laser displacement sensors using certified standards.

(2) Inspect coin-cell holders and pressure components for wear or deformation.

(3) Clean optical and sensing components to maintain measurement accuracy.

(4) Verify temperature and pressure control performance at regular intervals.

(5) Maintain software updates and perform routine data backups according to laboratory procedures.

在线联系供应商

Other supplier products

| Safety Helmets Acceleration Impact & Penetration Tester | The Safety Helmets Acceleration Impact & Penetration Tester is a dual-mode testing instrument designed to evaluate helmet performance under bot... | |

| Cleanliness Analysis System | Production: The cleanliness analysis system fully complies with the requirements of standards such as VDA19.1 - 2015. ISO16232. ISO4406. ISO4407. ... | |

| Catheter Vacuum Leak Tester | The Catheter Vacuum Leak Tester is a professional device used to detect leaks in medical catheter systems under vacuum conditions. Its primary purp... | |

| American European bending tester | Test Purpose: To determine if metal wires in children's products bend or break under stress, creating sharp edges or points that pose choking or i... | |

| ASTM F963 Nail Bed Flammable Tester | G963 Nail Bed Flammable Tester, It is suitable for the burning performance test of cloth toys and filling materials. Perform the flammability of th... |

Same products

| Falling Sand Abrasion Test machine | 卖方: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | 卖方: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | 卖方: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | 卖方: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |