Photovoltaic module outdoor exposure test system

The Photovoltaic Module Outdoor Exposure Test System is designed to simulate real-world environmental conditions for accelerated aging and performance evaluation of PV modules. It combines precise temperature, humidity, and solar irradiance control with advanced data acquisition and AI-based diagnostics, enabling rapid assessment of long-term durability, degradation modes, and energy harvesting efficiency.

Application

(1) Accelerated aging and performance testing of photovoltaic (PV) modules

(2) Qualification and type approval for PV modules under IEC 61215 and IEC 61730 standards

(3) Outdoor exposure simulation for desert, tropical, polar, and marine conditions

(4) R&D of solar module materials and encapsulation technologies

(5) Assessment of PID (Potential Induced Degradation), delamination, and hotspot formation

Standards

(1) IEC 61215 – Terrestrial Photovoltaic (PV) Modules: Design Qualification and Type Approval

(2) IEC 61730 – Photovoltaic (PV) Module Safety Qualification

(3) UL 61730 – Safety Standard for Photovoltaic Modules

(4) ISO 9060 – Solar Energy: Classification of Pyranometers

(5) CE Certification – Conformité Européenne

(6) Optional: IEC 60904 series for solar simulator calibration

(7) Optional: UL 1699B – Arc-Fault Detection

Features

Real-World Accelerated Aging: Achieves 10–15 year equivalence within 6 months using IEC-compliant damp heat and UV exposure.

Spectral Matching: AM1.5G filtered solar simulation ensures standardized irradiance.

Multi-Environment Testing: -40°C to +85°C chamber range with ±1°C stability and 95% RH for tropical/marine simulation.

Energy Harvesting Capability: Grid-tied system with MPPT tracking offsets up to 70% of power consumption.

Smart Data Acquisition: 16-channel logging of I-V curves, EL imaging, and thermal mapping.

AI-Powered Diagnostics: Machine learning predicts module degradation, including delamination and hotspots.

Safety Features: UL 1699B-compliant arc-fault detection and dual redundant emergency shutoff circuits.

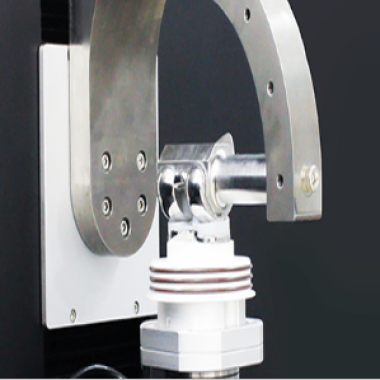

Product Flexibility: Dual-axis tracker (±60° tilt, ±180° azimuth) for precise solar alignment, modular design expandable from 5 kW to 50 kW.

Parameters

| Parameter | Specification |

|---|---|

| Solar Irradiance | 300–1,200 W/m² (AM1.5G filtered) |

| Temperature Range | -40°C to +85°C (operational) |

| Temperature Deviation | ≤ ±1°C (steady state) |

| Humidity Range | 10%–95% RH (non-condensing) |

| Chamber Volume | 2 m × 3 m × 2.5 m (expandable) |

| Power Supply | 380V/415V, 3-phase, 50/60Hz |

| Dimensions (W×D×H) | 2,500 mm × 3,500 mm × 3,000 mm |

| Weight | 1,200 kg (net) / 1,800 kg (gross) |

Accessories

(1) IEC 60904-4 compliant reference cells (4 pcs)

(2) Type T thermocouples with ceramic insulation (10 pcs)

(3) Software Suite: SolarTest Pro license (Windows/Linux), 1-year cloud-based PV simulation access

(4) Calibration & Safety: NIST-traceable irradiance meter, arc-flash protective gear (Class 2, 3 pairs)

(5) Maintenance Kit: Spare fuses, surge protectors, chamber cleaning solution (non-corrosive)

(6) Documentation: Multilingual quick-start guide (printed + digital), compliance certificates for IEC/UL/ISO standards

Test Procedures

Install PV modules on the dual-axis tracker and connect reference cells and thermocouples.

Configure test parameters via the 10” sunlight-readable HMI or select preloaded IEC/UL test sequences.

Set solar irradiance, temperature, humidity, and cycle duration as required.

Initiate the test sequence; the system automatically performs environmental cycling and data acquisition.

Monitor real-time measurements of I-V curves, thermal mapping, and EL imaging through HMI or remote access.

Upon completion, return chamber to ambient conditions before sample removal.

Export data reports via the software interface for analysis and documentation.

Maintenance Information

Clean solar simulator lamps, chamber surfaces, and tracker mechanisms regularly to ensure accurate irradiation.

Replace thermocouples, reference cells, and fuses as recommended by the manufacturer.

Perform annual calibration of irradiance meters and data acquisition channels.

Verify arc-fault detection circuits and emergency shutoff functionality before each test cycle.

Maintain chamber and tracker in a dry, ventilated environment when not in operation.

在线联系供应商

Other supplier products

| UV Test Chamber | Features and Benefits 1. STD UV-SI-260 is widely used in UV aging test, which can realize the comprehensive test of UV, temperature, humidity and ... | |

| Socks wear tester | Product Introduction: Socks wear tester is a special equipment, mainly used to test the wear resistance of socks material. It evaluates the comfor... | |

| Reciprocating Friction and Wear Testing Machine | Applicable Standards ASTM Standards: Formulated by the American Society for Testing and Materials (ASTM), standards such as ASTM D6079 are used to... | |

| Standard pacifier safety tester | Overview In the infant care industry, bottle quality directly impacts infant health. The NPNZ-01 Baby Bottle Mechanical Performance Tester is spec... | |

| Knee Joint Prostheses Wear Tester | Standard ISO 14243-1:2014: Specifies wear testing parameters for total knee prostheses, including axial loading, flexion/extension kinematics, and... |

Same products

| Falling Sand Abrasion Test machine | 卖方: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | 卖方: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | 卖方: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | 卖方: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |