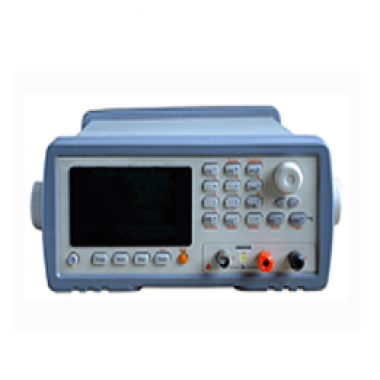

Photovoltaic module insulation resistance tester

The Photovoltaic Module Insulation Resistance Tester is a precision instrument designed for simultaneous measurement of insulation resistance and leakage current in PV modules. It ensures compliance with IEC 61215 and UL 61730 standards, providing reliable and non-destructive testing for residential, commercial, and utility-scale photovoltaic modules. The tester integrates advanced AI-powered diagnostics and auto-ranging functionality for efficient and accurate evaluation of module insulation integrity.

Application

The tester is suitable for:

Quality control in photovoltaic module production lines.

Research and development of module insulation materials.

Periodic inspection of installed PV modules for insulation degradation.

Testing for potential PID (Potential Induced Degradation) risks.

Standards

IEC 61215: Terrestrial Photovoltaic (PV) Modules – Design Qualification and Type Approval

UL 61730: Safety Standard for Photovoltaic Modules

ISO 17025: General Requirements for the Competence of Testing and Calibration Laboratories

CE Certification (Conformité Européenne)

Features

Dual-Parameter Testing: Simultaneously measures insulation resistance and leakage current, eliminating the need for separate instruments.

High Reliability: AI-assisted diagnostics automatically flag insulation breakdown patterns and predict PID risks.

User-Friendly Operation: Laser-guided probe placement ensures precise contact on textured module surfaces.

Non-Destructive Testing: Preserves sample integrity during measurement.

Environmental Compensation: Dynamic calibration corrects for temperature and humidity drift.

Safety Assurance: Dual redundant emergency circuits and E-stop ensure safe operation.

Integration Capability: Can interface with MES/ERP systems and cloud-based analytics for smart data management.

Parameters

| Parameter | Specification |

|---|---|

| Insulation Resistance | 100 kΩ – 10 TΩ (10⁵ Ω – 10¹³ Ω) |

| Leakage Current | 10 nA – 20 mA (auto-ranging) |

| Test Voltage | 1.0 – 1,000 VDC (0.1 V steps <100 V, 1 V steps ≥100 V) |

| Voltage Accuracy | ±1% (at 1,000 VDC) |

| Measurement Speed | 55 / 25 / 3 readings/second (high / medium / full) |

| Max Charging Current | 30 mA ±5 mA |

| Power Supply | 100–240V AC, 50/60Hz (universal adapter) |

| Dimensions (W×D×H) | 300mm × 250mm × 150mm |

| Weight (Net/Gross) | 5 kg / 7 kg |

Accessories

Testing Kit: 4x insulated test probes (10 kV rated), 10x alligator clip leads (red/black)

Software Suite: License key for InsulationAI Pro (Windows/macOS), 1-year free cloud-based analytics

Calibration & Safety: NIST-traceable resistance standards (1 GΩ, 10 GΩ), explosion-proof gloves (Class 00, 3 pairs)

Maintenance Kit: Spare fuses, probe tips, cleaning solution for optical components

Documentation: Multilingual quick-start guide (printed + digital), IEC/UL/ISO compliance certificates

Test Procedures

Install the PV module on the test fixture and connect the insulated probes.

Set the desired test voltage or allow auto-ranging to select optimal voltage.

Initiate the measurement sequence via the touchscreen HMI.

Monitor real-time readings of insulation resistance and leakage current.

Review AI-powered diagnostics for potential insulation defects or PID risks.

Record and export test results to local or cloud storage.

Maintenance Information

Inspect and clean probes and leads after each testing session.

Calibrate resistance standards periodically following NIST guidelines.

Check and replace fuses and probe tips as needed.

Ensure environmental conditions (temperature/humidity) are stable during long-term operation.

Store the tester in a dry, dust-free environment when not in use.

在线联系供应商

Other supplier products

| Big Combustion Chamber, DIN 54837,DIN 50055 | Products: With the rapid development of high-speed rail, rail rolling stock materials and components used in combustion performance testing requir... | |

| Gas Hazardous Characteristics Tester | Product Introduction This tester is used to test the flammable concentration range of gases in air. It is suitable for the vast majority of pure f... | |

| Corrosion Test Apparatus IEC 60754 Part 1 & 2,Corrosion Test Chamber | Description: This tester is used to test the acidity of the gas that released during combustion from cable or optical cable components material; T... | |

| Scrub Abrasion Test device | T107 Scrubbing Tester, It is suitable for various abrasion and wet scrubbing tests, which is commonly used in scrubbing resistance tests for interi... | |

| UL94 Horizontal/ Vertical Flame Test Machine,IEC 60695,UL 94 Flammability Chamber | This machine is designed according to plastic Materials flammability test; It is used to test flammability, burning rate, flame spread, burning fla... |

Same products

| Falling Sand Abrasion Test machine | 卖方: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | 卖方: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | 卖方: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | 卖方: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |