Powder Characterization

Powder characterizationincludes flow measurements, morphology, particle size distribution, density and chemical composition. Bettersize PowderPro Series instruments are mainly used for the analysis of the powder physical properties by testing items such as angle of repose and fall ,angle of spatula (flat plate angle) ,bulk and tapped density, dispersibility, voidage and cohesion ,angle of difference , compressibility , uniformity, flowability Index ,floodability Index ,sieve size, angle of slide,etc.

What are bulk density, tapped density and compressibility, flowability index?

Bulk density: fill the powder sample into a measuring cup, flatten the top, the ratio of the powder mass to the volume of the cup is defined as bulk density. It indicates the mass of the powder that can be added into the vessel per volume under the normal conditions.

Tapped density: fill the powder sample into a measuring cup; vibrate the cup at certain amplitude and frequency to remove air from the powders. After reaching the required vibration time, flatten the sample. The ratio of the powder mass to the volume of the cup is defined as tapped density. Tapped density indicates the mass of powders filled into the vessel per volume after excluding air from the powders. The data of bulk density and tapped density are often used for the design of vessels, bags, and tanks for powder storage.

Compressibility: it is the ratio of the difference between tapped density and bulk density to tap density. It shows the degree of volume reduction from bulk to tap state.

Flowability Index is a set of numerical values obtained by the weighted summation of angle of repose, Compressibility, angle of spatula, uniformity, and cohesion. It is used to comprehensively evaluate the flowability of the powder. The Flowability Index is mainly used to describe the powder flowability under gravity.

What are angle of repose, angle of fall, angle of difference, and flat plate angle (angle of spatula)?

Angle of repose: Under the static balance, the angle between the slope of a powder pile and the horizontal plane is angle of repose. It is measured when the powders fall to a surface via gravity and form a cone. It indicates the flowability of the powders. The smaller the angle of repose is, the better the flowability of the powders.

Angle of fall: After measuring the angle of repose, apply an external force to the powder pile to collapse it. The angle between the slope of the collapsed pile and the horizontal plane is defined as angle of fall.

Angle of difference: It means the difference between the angle of repose and the angle of collapse. The larger the angle of difference is, the better flowability of the powders.

Flat plate angle: immerse a plane in the powder pile; pull up the plane vertically, one angle is formed between the slope of the powders on the plane and the plane. Apply an external force to obtain another angle. The average of these two angles is flat plate angle. The smaller the flat plate angle is, the better the flowability of the powders. The flat plate angle is usually larger than the angle of repose.

How to measure flowability of metal powders?

According to GB1482 and ISO4490, the flowability of metal powders is usually measured with a Hall flow meter.

The measurement process is:

• Weigh 50g + 0.1g sample;

• Plug the hole in the funnel with the finger;

• Pour the sample into the funnel;

• Quickly remove the finger from the small hole and starting the stopwatch at the same time (precision 0.2S);

• Wait until the powder sample runs out, and stops the timing immediately;

• Evaluate the fluidity of the metal powder through the time of the 50g powder passing through the hole.

The standard funnel of Holl flowmeter needs to be calibrated by standard sample with the flow speed of 40 + 0.5s/50g.if you need particle measurement, please contact us.

We provide the best service and technical support for your using the particle size instrument.

Bettersize has a support team that continually provides improved hardware, software of particle size analyser

and ease of use updates of particle size instrumentto its large customer base. For assistance in any of these aspects contact our global support team or our local distributors.

在线联系供应商

Other supplier products

| Laser Diffraction | Particle size measurement using static light scattering (Particle size determination by laser diffraction) The particle size distribution as a par... | |

| HFlow 1 Metal Powder Flowability Tester | Bulk Density Tester BeDensi B1 bulk density testingequipment adopts natural deposition method. BeDensi B1bulk density instrument’s manufactur... | |

| Powder Characterization | Powder characterizationincludes flow measurements, morphology, particle size distribution, density and chemical composition. Bettersize PowderPro S... | |

| HFlow 1 Metal Powder Flowability Tester | BeVision D2 is a microscopic image particle size and shape analysis system. The dry dispersion aims at coarser and even millimeter range powder mat... | |

| Bettersizer 2600 | Bettersizer 2600 Laser Particle Size Instrument(Dry & Wet Dispersions) The Bettersizer 2600 utilizes this laser diffraction technology. The... |

Same products

| Leather Bursting strength testing machine | 卖方: G238BB ElecStandard International Group (HK) Limitedtronic Crockmeter | TRANSLATE with x English Arabic Hebrew Polish Bulgarian Hindi ... | |

| Ureaplasma Urealyticum Fluorescent Polymerase Chain Reaction Diagnostic Kit | 卖方: Daan Gene Co., Ltd. | Ureaplasma urealyticum is a type of bacteria that can cause infection of the urinary tract and va... | |

| Pathology Test | 卖方: Daan Gene Co., Ltd. | What Is Pathology Diagnosis? Pathology is focusing on the nature, cause, origin, and development... | |

| Low Power SPD | 卖方: Shanghai Chenzhu Instrument Co., Ltd. | The low voltage surge protection deviceis designed to prevent transient surge conditions. T range... | |

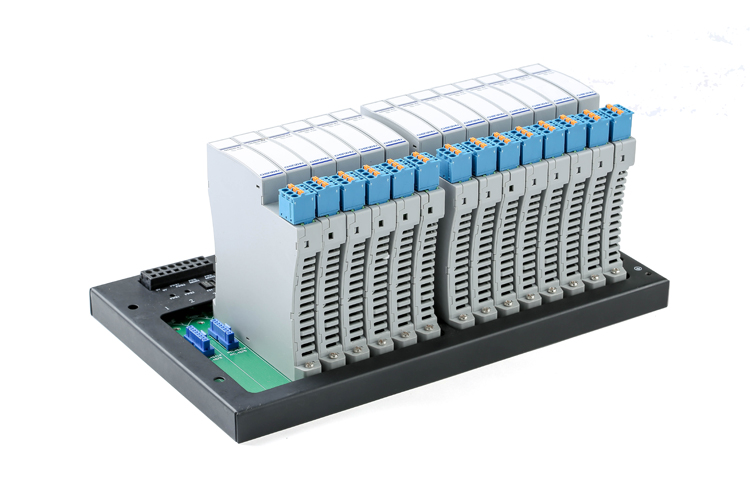

| Intrinsic Isolated Barrier | 卖方: Shanghai Chenzhu Instrument Co., Ltd. | Isolated barrier uses intrinsically safe explosion-proof and functional safety technologies and a... |