During Production Inspection

During Production InspectionSFA=Simple Factory AuditEFA=Extensive Factory AuditSA=Social AuditLT=Lab TestingPPI=Pre-production InspectionIPI=Initial Production InspectionDPI=During Production InspectionDSS=Defect Sorting ServicePM=Production MonitoringPSI=Pre-shipment InspectionCLS=Container Loading SupervisionWhat is the During Production Inspection? The During Production Inspection (DPI) will take place during production between 20% and 80% of the manufacturing process. We check packed and ready to go products. What do we check during a During Production Inspection? Product appearance (AQL), workmanship quality, size measurements, weight check, functionality assortment, accessories, labeling & logos, packaging, packing and other tests and special requirements, depending on the product and the export market. The During Production Inspection(DPI) will also cover the raw materials, unfinished products and the planning of production. Our team of inspectors chooses a specific quantity of completed products, according to AQL tables - and inspects them according to your specifications, requirements and according to our protocols and expertise. After completing the During Production Inspection, a fully detailed inspection report with pictures and comments is sent to you. Then you are able to Accept or Reject your shipment online. The added value of a During Production Inspection? We will intervene in the middle of the production process, we check if the quality of your products reaches your standards and we make a statement of your production schedule. We inspect the actual production volume to avoid any delays in your final shipment. At this stage, you can still modify the production protocol and still be on time with your order in case of problems.Highlights of this quality control inspection service·Assure that the mass production quality is the same as the golden sample:·Implement the necessary corrective actions before having too many defects·Be aware of the percentage of defects of finished products·The exact statement of the production planning:·Avoid unnecessary costs and delaysWhy should I book this During Production Inspection? Because you might want to check if the production is running smoothly, especially if no FAI were performed during the first processes of the production. Because of you should keep pressure on your vendor's shoulders and because trust is good, but control is better.

Other supplier products

|

|

|

Factory Evaluation,Website: Audit Programs |

|

|

|

During Production InspectionSFA=Simple Factory AuditEFA=Extensive Factory AuditSA=Social AuditLT=Lab TestingPPI=Pre-production InspectionIPI=Initia... |

|

|

|

Initial Production InspectionSFA=Simple Factory AuditEFA=Extensive Factory AuditSA=Social AuditLT=Lab TestingPPI=Pre-production InspectionIPI=Initi... |

|

|

|

Other Services,Website: Inspection |

|

|

|

Pre-Production InspectionSFA=Simple Factory AuditEFA=Extensive Factory AuditSA=Social AuditLT=Lab TestingPPI=Pre-production InspectionIPI=Initial P... |

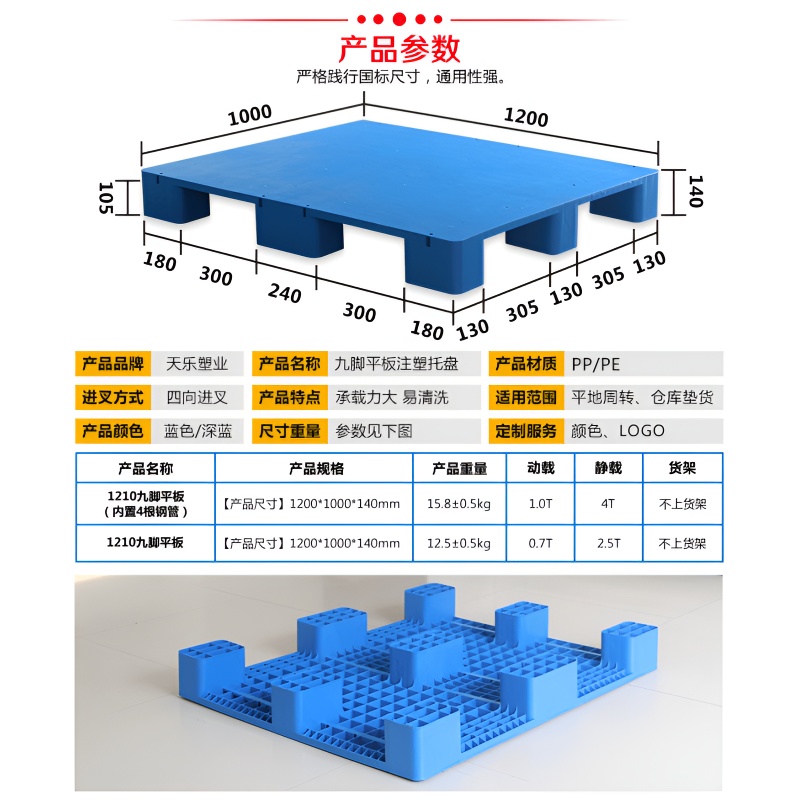

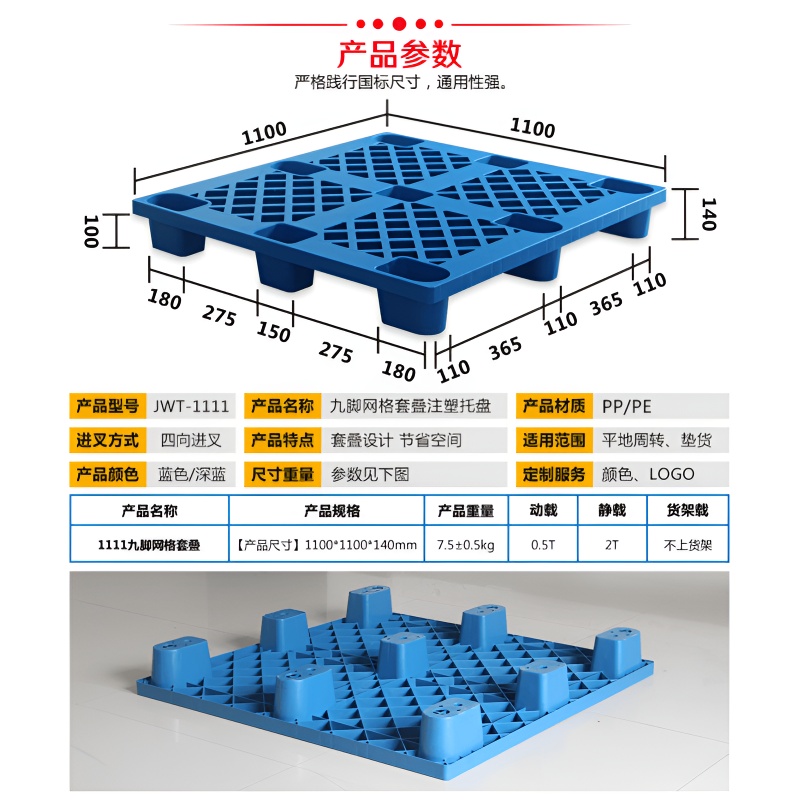

供应产品

Same products