HH810 air jet loom

HH810 air jet loom

Air jet loom weavingis especially popular with customers producing plain fabrics and high density fabrics. HH810 is designed with the concept of providing superior airjet weaving performance with economical price for our customer. It is the most ideal air jet weaving machine for customers to develop top-grade weaving fabric, improve fabric quality, reduce environment pollution, reduce labor cost and increase economic efficiency.

SALIENT FEATURES

High speed—New weft insertion, new frame structure and high speed CPU ensure the maximum running speed of 1200RPM.

Low energy consumption—New weft insertion and energy saving design of main & auxiliary nozzle realize less air consumption.

Low vibration—Using 3D design and computer analysis to optimize the frame structure including the cross rail connections, and to realize light-weight design and optimum balance of the beating motion. These improvements ensure lower vibration and high stability during high speed operation.

Flexibility and wide applicability—A wide range of standard configuration and a variety of optional parts have enabled the loom to weave fabrics that are mostly woven by rapier looms, including wide home furnishings fabric, tyre cord fabric, electronic glass fabric, fabric of different yarn types and counts, airbags, seersucker and folding edge fabrics.

Easy operation & new Electronics—Relatively lower machine, inhead type temple are both beneficial for the operation; The loom is also equipped with Internet communication technologies, multi-functional control panel with advanced high speed CPU.

|

DOUBLE BACK ROLLERS Double back rollers detect and maintain the correct warp tension regardless of the beam diameter size. |

NEGATIVEEASING Negative easing is provided for weaving lightweight fabrics like filament and glass fiber. |

|

POSITIVE EASING Positive easing is ideal for a wide range of fabrics, particularly heavy and high density fabrics. It also offers consistent synchronized movement during high speed operation. |

DOUBLE BEAM(UPPER & LOWER) Independent servomotors for the upper and lower beams are provided for weaving fabrics with different types of warp yarn. |

|

ELECTRONIC TAKE-UP Weft density settings can be entered from the function panel(single pick density type). This system can also change weft density during loom operation(multiple pick density type) |

ELECTRONIC TAKE-UP Weft density settings can be entered from the function panel(single pick density type). This system can also change weft density during loom operation(multiple pick density type) |

|

NEGATIVE CAM SHEDDING, MAXIMUM 8 SHAFTS We have successfully developed a high-performance solenoid valve with a smaller size and quicker response, which eliminates waste in air consumption and can support short-pitch sub nozzles. The 65mm short-pitch nozzles ensure the successful weft insertion even at low pressure. |

|

|

CRANK SHEDDING, MAXIMUM 4 SHAFTS It is ideal for high quality plain structure fabric. |

DOBBY SHEDDING, MAXIMUM 16 SHAFTS It can weave plain, twill, satin and high value-added jacquard fabrics. |

|

POSITIVE CAM SHEDDING, MAXIMUM 8 SHAFTS It is suitable for weaving plain, twill and satin fabrics, especially good for high-density fabric and wide fabric. |

JACQUARD SHEDDING Suitable for all kinds of jacquard fabrics. |

TECHNICAL PARAMETERS

| Item | Specification | Optionalconfiguration | |

| Reedspace | Norminalwidth(cm) | 150,170,190,210,230,250,280,340,360 | |

| Effectivereedwidth | 0~60cmreductionfromnorminalwidth(150~250cm) | ||

| 0~80cmreductionfromnorminalwidth(above280m) | |||

| Yarnrange | Staplefiber:Ne100~Ne2.5Fliament:56dtex~1350dtex | ||

| Weftfillingselection | 1-coloror2-colorsmixing,4colors,6colors | ||

| Drive | rush-startermotordirectdrive | Independentvariablefrequency | |

| Push-buttonoperationwithbothhands | |||

| Powerrating | 2.7KW,3.0KW,3.7KW,6.5KW | ||

| Weftinsertion |

Mainandsub-nozzlecombinedsystem,profilereed,auxiliarymainnozzle |

Stratchnozzle,WBSweftinsertionbreak,

FICweftinsertionfuzzycontrol,mainnozzlegripper |

|

| Newsolenoidvalvewithbuilt-inmanifolds | |||

| Independentsub-nozzletimingcontrolbycolor | |||

| AJCautocontrol,firstpickcontrol | |||

| Shedding | Crankplainsheddingwith4shafts | ||

| Positivecamsheddingwithmaximum8shafts | |||

| Negativecamsheddingwithmaximum8shafts | |||

| Dobbyshedding(electronic,positive,underneathtype)withmaximum16shafts | |||

| Electronicjacquardshedding | |||

| Letoff | Electroniclet-off(ELO),withkickbackfunction | ||

| Doublebeam | |||

| Negativeeasing | |||

| Positiveeasing | |||

| Beamdiameter | 800mm,914mm,1000mm | ||

| Takeup | Electronictakeup(ETU) | Automaticdensitychangefunction(8densities) | |

| Maximumon-loomclothrollerdiameter | 600mm(cam,dobby,electronicjacquardshedding)520(crankshedding) | ||

| Pickdensity | 5.9~118.1picks/cm | ||

| Wovenlengthcounter | Displayonscreen(meter/yarn),withpresetcounterfunction | ||

| Templecylinder | Top-mountedtype(inclinedclothpassagetowardloomfront) | Lowmountedtype | |

| Beating | Cranktypebeating,multiplesleybeatingmechanism | ||

| 4links(reedwidthbelow230cm) | |||

| 6links(reedwidthabove250cm) | |||

| Intermediaterocking-shaftsupporter,rockingbalancer | |||

| Measuring&storage | brushlessDCmotorweftaccumulator | Balloonbreaker | |

| Weftfillingstand | Floormountedfor4packages(2colors),

floormountedfor8packages(4colors) |

Floormountedfor10packages(6colors) | |

| Selvage | Planetarygearmotion | mechanicaltuck-indevice(left&right,middle)aircontroltuck-indevice(left&right,middle) | |

| Wasteremove | Catchcordtype(3-rolltype),catchcordtype(geartype) | ||

| Weftcutting | Mechanicalcutter | Electroniccutter | |

| Lubrication | Oilbathsystemformaindrivingparts,centralizedlubrication(manualgreasing) | Automaticgreasing | |

| Stopmotion | Weftyarnbreakage | Reflectiveweftfeeler | |

| oneheadsystem,twoheadsystem | |||

| Warpyarnbreakage | Electrical6-rowcontactbarsystem | Rotarysensor | |

| Others | Stopmotionforselvageandcatchcordyarn | ||

| Stopreasonindication | indicationbymessageonscreen | ||

| 4colormulti-functionindicationlamps | |||

| Automation | Datasetting,automaticcontrol,monitoring,self-diagnosisfunction | ||

| Pickingfinding | Automaticpickfinder | ||

| Slowinchingbyinverter(forward,reverse) | |||

| Others | Networkapplication | ||

| Special | Selvagejacquard |

在线联系供应商

Other supplier products

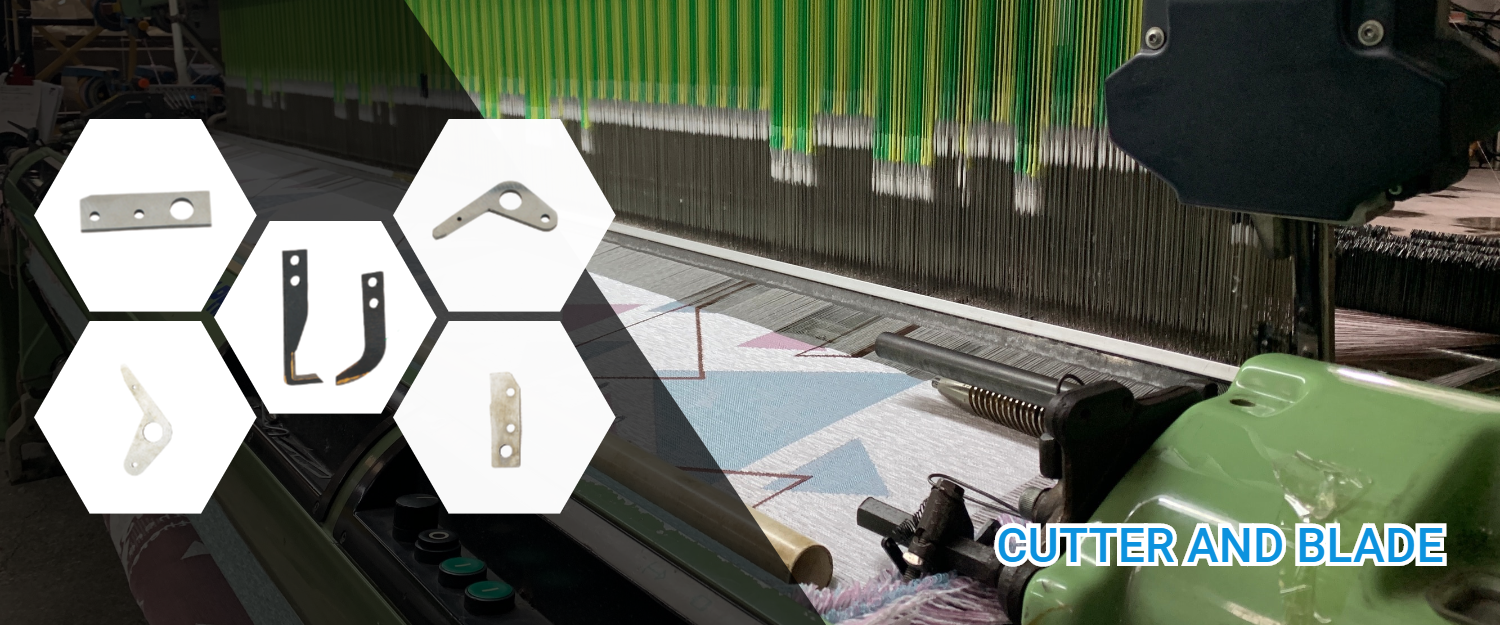

| Cutter & Blade | Sino Textile Machinery is consisted by a group of manufacturers of textile machinery and spare parts. We specialized in textile weaving machinery, ... | |

| GA738-II Towel Loom | GA738-II Towel Loom GA738-II underneath type dobby towelloom machinehas been released to the market for a long time and received good feedba... | |

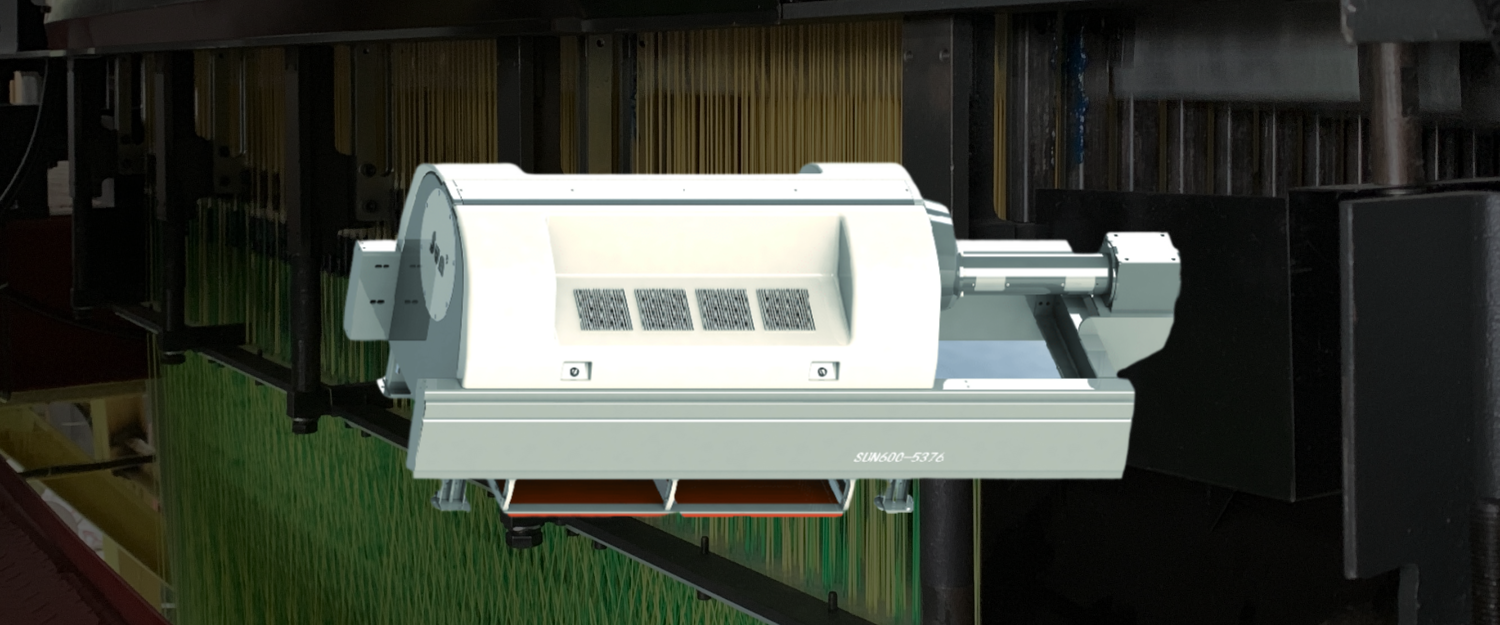

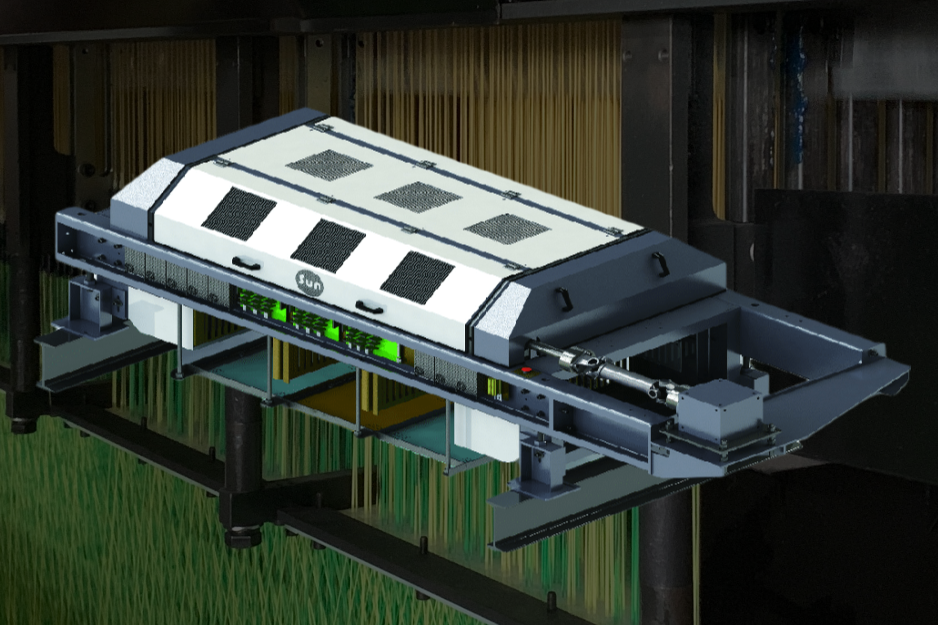

| Sun600 Jacquard Machine | SUN600 series high speed jacquard machineis suitable for high speed rapier loom, water jet loom and air jet loom. It is ideal for weaving label, t... | |

| Weaving Machinery | Types of Weaving Machines by Sinotextile Weaving machines play the most important role in textile machinery as they are used to weave different kin... | |

| DF31 Rapier Loom | DF31 Rapier Loom DF31 high speed rapier loom is designed according Europeanlarge weaving loomand can realize all the functions of its counte... |

Same products

| RFAW20 High-Speed Assembly Winding Machine | 卖方: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | RFAW20 High-Speed Assembly Cone Winding Machine This product is a new assembly winder machine wi... | |

| RF310 Filament Fiber Two-For-One Twister | 卖方: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | RF310 Filament Fiber Two-For-One Twister Since the launch of the first set two for one twisterin... | |

| Through-Hot Air Bonding Non-woven Fabrics Production Line | 卖方: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | Through-Hot Air Bonding Non-woven Fabrics Production Line The Through-hot air through nonwoven f... | |

| Spun-Laced Non-woven Fabrics Production Line | 卖方: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | Spun-Laced Spunbond Non Woven Fabric Machine The spunlace linefrom RIFA is a cutting-edge system... | |

| Needle Punched Non-woven Fabrics Production Line | 卖方: ZHEJIANG RIFA TEXTILE MACHINERY CO., LTD | Needle Punched Non Woven Needle Punching Machine The Needle Punched Non-woven Fabrics Production... |