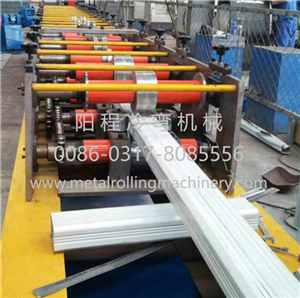

Downspout Roll Forming Machine Taking with Elbow Machine

We also can design the machine strictly according to above profile drawing.

SURFACE TREATMENT

1). mainly consists of decoiler, roll forming system, cutting system, hydraulic system, control system, and product receiving table.

2). is the complementary equipment for downspout forming machine. It can make curve for downspout to meet the requirement of practical engineering projects.

3). Work Flow:

decoiler --- coil sheet guiding and feeding device --- roll forming system---cutting system--- product receiving table---elbow machine

4). Main Technical Specification

Suitable raw material: 0.3-0.6mm colored steel sheet

Main motor power: 4kw+4w for roll forming; 3kw for cutting

Forming speed: 4-10m/min

Roller station: 23 steps

Roller material: Cr12 steel with vacuum heat treatment, hardness reaches 58HRC-60HRC

Active shaft material: 45#steel with high frequency surface treatment and grinding process

Material of cutting die: Cr12MOV

Shaft diameter: Ф60mm

Stand wall plate thickness: 22mm

Cutting system: fly sawing, automatic cut to any length you need

Control system: Taiwan Delta PLC computer control system

Dimension of the machine: About 16000mm*1500mm*1400mm

5)

TECHNOLOGY

3t manual decoiler→guiding platform→main roll forming machine→cutting system→2m output table→elbow machine, two 4kw electric-motors, 3kw electric motor for cutting, PLC control system

SALES TERMS

1). Machine Price: Please contact us, we will try to give you good discount for starting our cooperation

2). Payment term: 30%TT should be paid as advance deposit, 70%TT before shipment

Or 100% LC at sight

3). Package: naked with simple plastic film and loaded in one 20-feet container

4). Delivery time: 50 working days after receipt of the deposit

5). Guarantee: 12 months. If any part of machine breaks, we will supply it for free.

6). After sales service

This producing line is maintained free of charge for 12 months. When the machine is used in China, we will install and debug the machine for free; if it is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians traveling abroad, and pay 100USDdayperson.

在线联系供应商

Other supplier products

| Metal Stud&Track Roll Forming Machine | Roll forming machine Cold forming machine Roll former SURFACE TREATMENT 1) Processing material: steel strip 2) Material thickness: 0.8-1.0mm ... | |

| Downspout Roll Forming Machine Taking with Elbow Machine | We also can design the machine strictly according to above profile drawing. SURFACE TREATMENT 1). mainly consists of decoiler, roll forming syste... | |

| YC Changeable Metal Profile Roll Forming Machine | YC We also can design the as per your required profile drawings SURFACE TREATMENT 1) Processing material: steel sheet,galvanized sheet or col... | |

| 65-Ton Clamp Punching Machine with Auto Feeding Device | 65-Ton Punching Machine We can also design the according to your required profile. SURFACE TREATMENT (1) Processing material: steel trip (2) Mater... | |

| Door Panel Forming Machine | SURFACE TREATMENT 1) Processing material: aluminium/zinc/galvanized steel/colored steel coil 2) Material thickness: 0.3-0.7mm 3) Effective width:... |

Same products

| 微型攻丝钻头迷你机用螺钉钻头丝锥套装公制螺纹螺钉螺塞钻头小型攻丝钻头工具 | 卖方: 徐州途智工具有限公司 | • 10种不同尺寸:M1、M1.2、M1.4、M1.6、M1.7、M1.8、M2、M2.5、M3、M3.5(粗线),用于点燃不同的灯丝。 • 标准公制螺纹设计,清晰整洁,无耙... | |

| 1/8“3/16”1/4“5/16”3/8“1/2”高速钢高速钢四槽直柄铣刀 | 卖方: 徐州途智工具有限公司 | •产品名称:立铣刀;材料:高速钢 •全面的尺寸范围——包括8种流行尺寸:1/16英寸、5/32英寸、1/8英寸、3/16英寸、1/4英寸、5/16英寸... | |

| TCMT32.51 TCMT16T304 10件套tcmt-32.51硬质合金刀片外部车削刀片钢制零件和不锈钢STFCR车削刀架切削刀具 | 卖方: 徐州途智工具有限公司 | • 型号:TCMT16T304/TCMT32.51 • 特点:适用于各种钢、不锈钢和铸铁工件的精加工和半精加工,如45#钢、弹簧钢、H13钢、42Cr钢。即使在非常肮脏的环境... | |

| FD-6TH Self Drilling Screws Making Machine Stainless Steel Screw Machine Price Manual Thread Rolling Machine Price | 卖方: 深圳飞道尔实业有限公司 | ||

| 钨钼钽原材料及加工件 | 卖方: 宝鸡晟译有色金属有限公司 |