Die casting

The Die Castng involvs 3 key elements: die casting machine, the mold and the alloy materials, the die casting could be described as the process of combining pressure, speed and time to achieve a ideal casted meatal part. The pressure applied during the casting process is the different feature from other casting method. Typically the melted metal was filled into the mold with high pressure and speed, and solidification under pressure as well to forming the casted part. Usually the pressure applying during the casting process is over dozens Mpa, with meatal pouring speed of 16~80 m/s, the liquid metal only takes 0.01~0.02 second to fully fill the die cavity.

Description of Die Casting

Die casting is a casting method in which a liquid or semi-solid metal or alloy, or liquid metal or alloy containing an enhanced phase, which is filled into the cavity of a die casting mold at a high rate under high pressure, and the metal or alloy is solidified under pressure to form a casting. The pressure commonly used in die casting is 4~500MPa, and the die cast metal filling speed is 0.5-120m/s. Therefore, high pressure and high speed is the fundamental difference between die casting method and other casting methods and is also an important feature.

The principle of die casting is mainly the principle of pressure injection molding of the metal fluid. The die casting conditions are usually set by adjusting the speed and pressure on the die casting machine, as well as the switching position of the speed, and the rest is selected in the die casting mold line.

Features of Die Casting

Die casting is a casting method in which molten alloy liquid is poured into a press chamber, filling the die casting mold cavity of a steel mold at high speed and causing the alloy liquid to solidify under pressure to form a die casting mold.

The main feature of die casting that distinguishes it from other casting methods is high pressure and high speed.

①The die cast metal fluid is filled into the die casting mold cavity under pressure and crystallized and solidified under higher pressure, commonly 15-100MPa.

②The die cast metal liquid fills the die casting mold cavity with high speed, usually at 10-50m/s. Some can also exceed 80m/s, (the linear speed of the cavity through the internal gate-internal gate speed), so the filling time of the die cast metal liquid is very short, about 0.01-0.2 seconds (depending on the size of the casting and difference) within. The die casting mold cavity can be filled within 0.01-0.2 seconds (depending on the size of the casting).

Advantages of Die Casting

The die casting process has several obvious advantages such as high production efficiency, low operation skills requiring, high accuracy, and tolerance class for the finished product. As a result, a portion of raw material is saved and further machining process is not required either. Also, the die casting is able to produce detailed parts, which is a perfect option for the big amount of pieces production. So generally speaking, the die casting is considered to be efficient, economic, a broad range of shape capable, long life, versatile applied casting process. Especially for the aluminum and alloy die cast metal parts, it has been widely applied.

Application of Die Casting

Due to the advantages of die casting, it is widely used, mainly in the mass production of non-ferrous alloy castings.

In the die casting production, accounting for the largest proportion is aluminum alloy die casting, which is 30% to 50%; followed by zinc alloy die casting; copper alloy die casting accounted for 1% to 2%. Application of die casting most is the automobile, tractor manufacturing, followed by instrument manufacturing and electronic instrument industry, and then agricultural machinery, defense industry, computer, medical equipment, and other manufacturing industries.

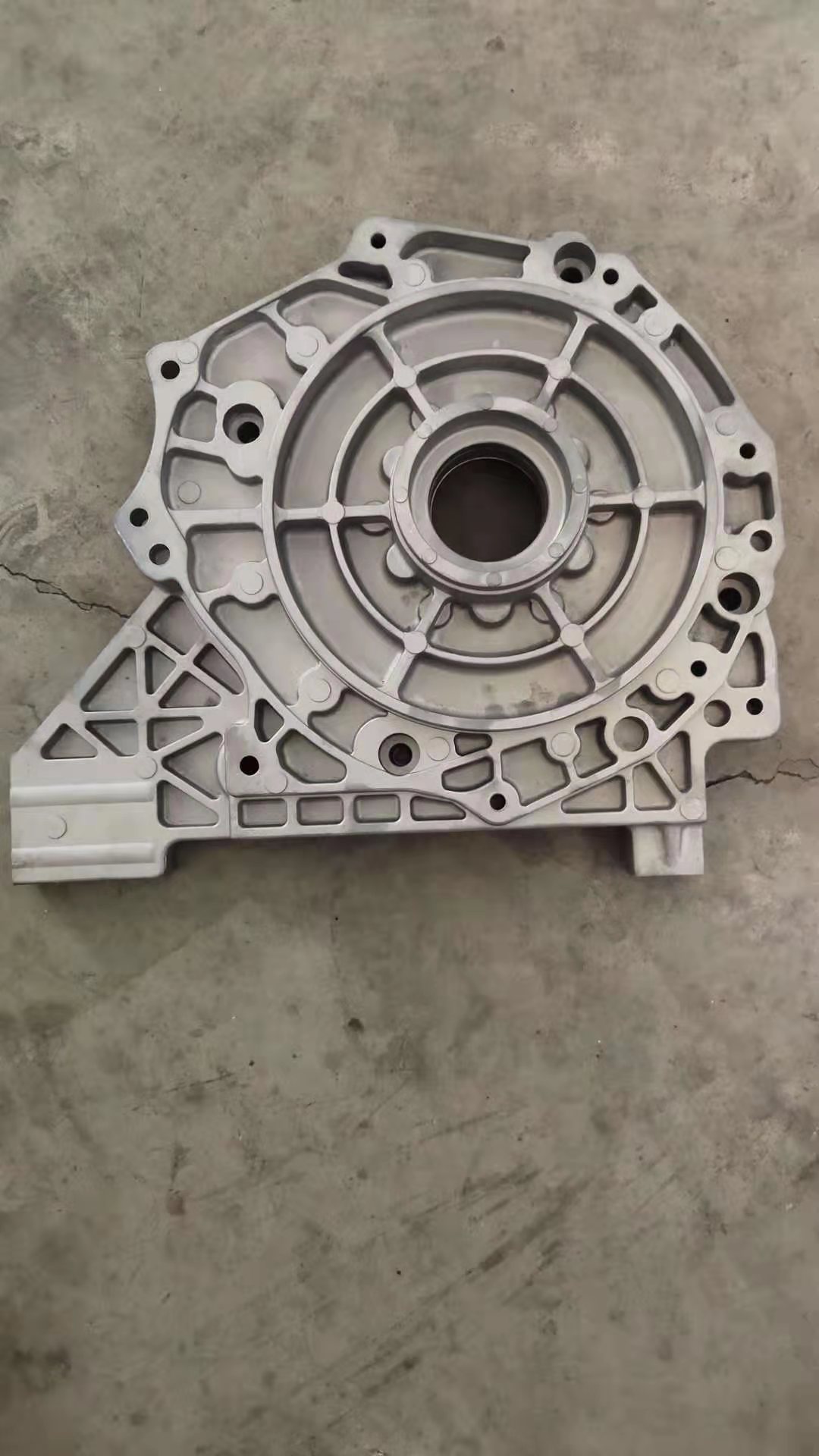

The parts produced by die casting mold are engine cylinder block, cylinder head, transmission case, engine cover, instrumentation and camera shell and bracket, pipe fittings, gears, etc.

In recent years, high technology has been applied to the field of the die casting mold. Such as the use of a three-stage injection mechanism to control the pressure, injection speed, and gas in the mold. The development of special die casting processes (such as vacuum die casting, directional pressure casting, oxygen die casting, etc.) and the application of computer control technology, effectively remove the pores, improve the density of the casting, while developing new die casting mold materials and heat treatment of new technology to extend the service life, so that the ferrous die casting metal has made some progress.

Why die casting is used?

Rayforce Manufacture is a private metal casting factory, we provide cold chamber die casting process pdf, aluminium casting defects and remedies pdf,high precision die castingand etc. Want to buy die castingor know what is die casting in manufacturing process, types of gravity die casting? Please contact us.

在线联系供应商

Other supplier products

| Green Sand Casting | Sand casting means the main material consisting of the mold is sand, and the melted metal fills the casting cavity only by its gravity. Generally, ... | |

| Investment Casting | Direct investment casting, also called the lost-wax casting process, is actually an ancient metal investment casting technologywith a history of ov... | |

| Aluminum Casting | Aluminum is a lightweight metal with silvery-white color. Because of its chemical features, aluminum never exists in the metallic form in nature. B... | |

| Metal Casting | Casting process usually refers to the metal casting process, is one of heating processing technologies handled by humans can be found recorded as e... | |

| Resin Sand Casting | Resin sand castingis a kind of floor molding process, by mixing the resin with quartz sand and solidification agent, to create the very hard and so... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |