Vacuum Die Casting

The vacuum pressure casting, as this name indicates, is casting method which the major processes including the melting, pouring, solidifying are performed inside the vacuum chamber. The vacuum is able to minimum the gas content of the product, and prevent further oxidation happening to the metal. This is a quite expansive technic, manufacturing the special alloy steel and oxidate-like titanium casting part can use this method to achieve a very high specification requirements.

Vacuum Die Casting Process

The vacuum die castingis further modified technic to the vacuum casting. It is vacuum assisted high pressure die castingmethod but the main process performs after a certain degree of vacuum building up. The degree of vacuum is about to be 50~80 kPa. In practice, there're 2 major kind of method for the vacuum die casting:

Vacuum Die Casting VS Traditional Casting

Compared with traditional casting, the same thing is: both are made by pouring molten or semi-molten metal into the mold, and then the required part is obtained by cooling and solidifying the metal.

Differences from traditional casting.

Advantages of Vacuum Die Casting

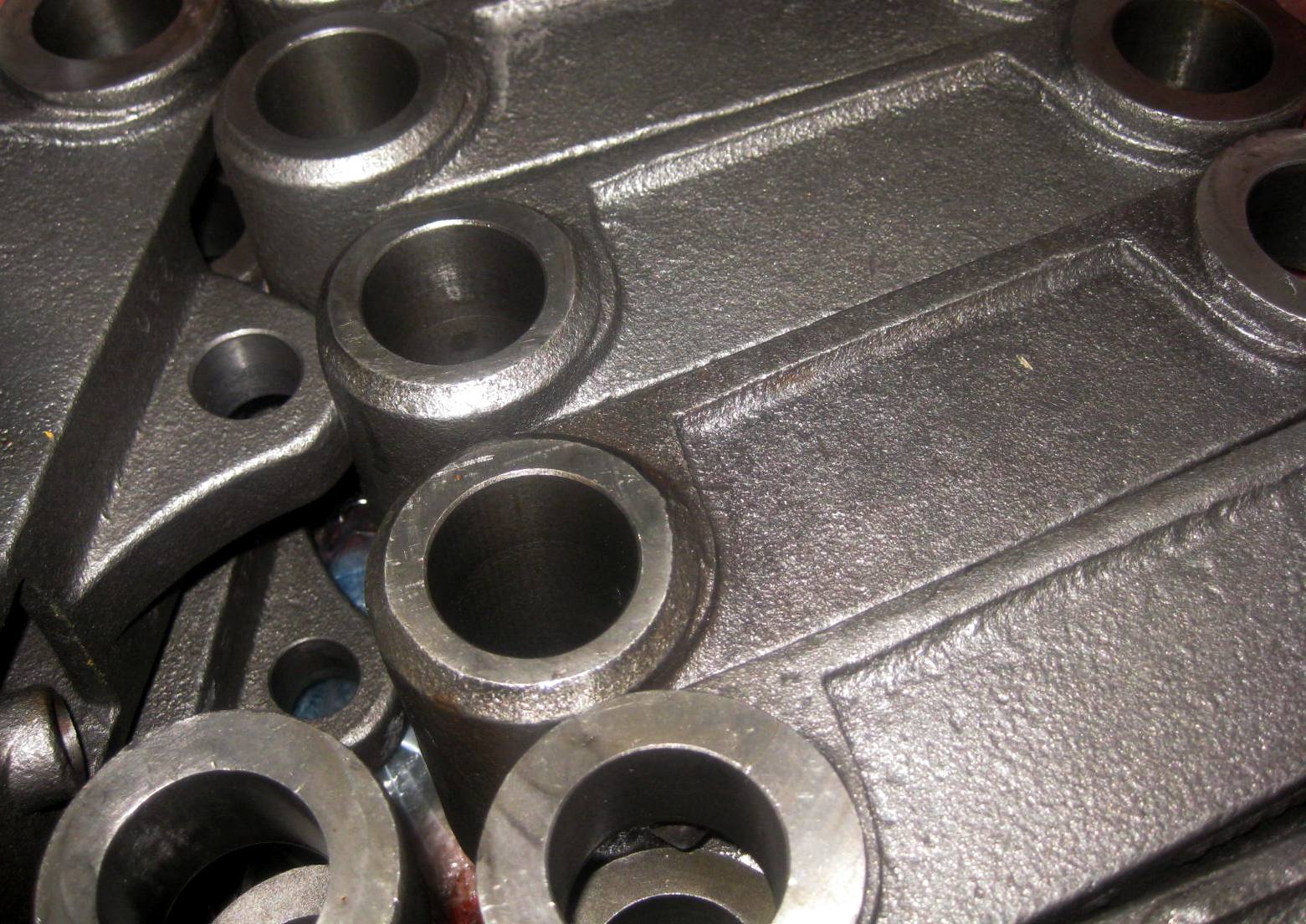

Vacuum molding is a physical molding method, which combines vacuum technology with sand casting, relying on plastic film to seal the cavity surface and the back of the sand mold, with the help of vacuum pump pumping to generate negative pressure, resulting in the pressure difference inside and outside the sand mold so that the mold sand is tightly formed, after placing the sand core, closing the mold, casting, waiting for the casting to solidify, lifting the negative pressure or stop pumping, the mold sand will then collapse and get the casting. According to the current field of application, it can be mainly divided into vacuum sealed mold making (V method) and solid vacuum casting (FV method). The advantages are:

(1) Moderate vacuum, high die cavity tightness and high casting quality.

(2) Vacuum casting with computer simulation of mold flow analysis, can predict the generation of casting defects, for the design of the mold making scheme, can significantly save time and improve production efficiency.

As one of the most professional casting suppliers, we provide metal casting china, cast iron and ductile iron, custom stainless steel castingand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Resin Sand Casting | Resin sand castingis a kind of floor molding process, by mixing the resin with quartz sand and solidification agent, to create the very hard and so... | |

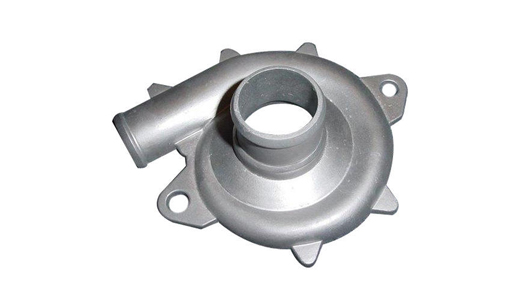

| Low Pressure Die Casting | The low pressure casting machineis to let the melted metal flow into the casting mold under a certain degree of pressure, and solidify the casting ... | |

| Green Sand Casting | Sand casting means the main material consisting of the mold is sand, and the melted metal fills the casting cavity only by its gravity. Generally, ... | |

| Ductile Iron Casting | Ductile ironis a type of graphite-rich casting iron, but it has not a long history that it was discovered in 1943. Ductile iron actually is not ... | |

| Art & Home Sculptures | Sculpture Moulding and Casting Rayforce's metal casting artcan be applied to Home accents, casting crafts, home sculpture, umbrella base, table ... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |