Application

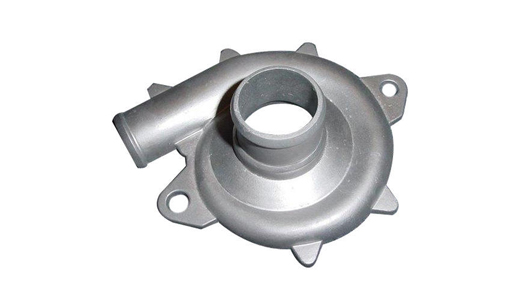

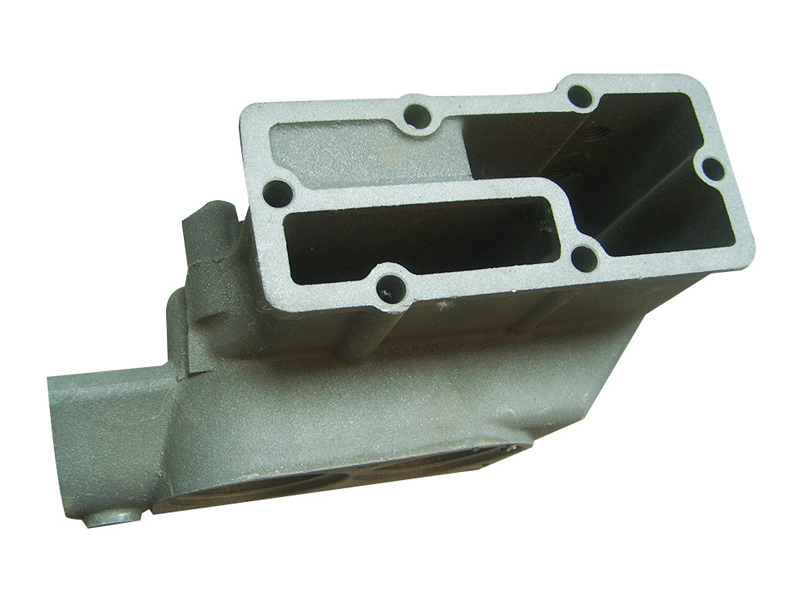

Metal casting applications

Marine

Rayforce's metal casting can be applied to anchor, stern frames, anchor winch part, container corner castings, propeller boss, etc.

Nuclear & Power Plant

Rayforce's metal nuclear castings can be applied to heat exchange machines, boilers, economizer parts, chemical engineering casting parts, water treatment parts, etc.

Almost all industrial sectors need to use cast steel parts, in ships and vehicles, construction machinery, engineering machinery, power station equipment, mining machinery and gold equipment, aviation, and aerospace equipment, oil wells, chemical equipment, and other industries. As for the application of cast steel parts in various industrial sectors, the situation may vary greatly due to the specific conditions of each country.

The variety of cast steel parts is too numerous to mention.

Power Station Equipment

Power station equipment is a high-tech product. Its main parts are under high load for a long time in continuous operation, thermal and nuclear power station equipment. Many parts also need to withstand high temperature and high-pressure steam corrosion, and thus the reliability of the parts have very strict requirements. Nuclear castings parts can meet these requirements to the maximum extent, widely used in power station equipment.

Mining Equipment

In order to ensure operational safety, some key parts of the mining equipment are stainless steel precision casting parts, such as the stranded cable wheel (sky wheel) and the main parts of the mine car, etc.. As for the processing of ore crusher and ball mill, due to the operation of the parts by a large impact load, jaw plate, hammerhead and liner plate, and other parts resistant to impact wear are high manganese cast steel parts, the frame is mostly carbon steel or low alloy cast steel parts.

Forging and Metallurgical Equipment

Forging machinery seat, cross, crossbeam, frame and gold equipment rolling mill frame, bearing seat and other important parts are traditionally cast steel parts. In addition, a considerable part of the roll of the rolling mill is also nuclear castings parts.

High-pressure Vessel Equipment

The core parts of the blowout preventer for oil and gas wellhead containment are low-alloy steel or martensitic stainless steel castings, such as the shell and top cover. Since these parts are subjected to pressures of up to 140 MPa, it is important to ensure the surface quality and internal quality of the castings when casting these nuclear castings parts.

Rayforce Manufacture is a private foundry manufacturer, we provide metal casting china, vacuum die casting, die casting automotive parts, die casting automotiveand etc. Want to know more about metal casting industryand casting application? Please contact us.

在线联系供应商

Other supplier products

| Lost Wax Investment Casting | The lost-wax casting process can differ depending on the application and the requirement, but it generally consists the following steps: Molde-maki... | |

| Low Pressure Die Casting | The low pressure casting machineis to let the melted metal flow into the casting mold under a certain degree of pressure, and solidify the casting ... | |

| Agriculture & Vehicle | Die Casting in Automotive Industry Rayforce's metal casting truckcan be applied to plough, tractor part, soil cultivation, planting, harvesting,... | |

| Compressors & Gears | Rayforce's metal die casting gearscan be applied to Turbo blowers, air control components, piston compressors, casting gears, etc. Application o... | |

| Sand Casting | Sand casting is the most commonly applied method for casting the metal part. It suits most of the raw materials, ferroalloy, and non-ferroalloy bot... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |