Aluminum Die Casting

what is aluminum die casting

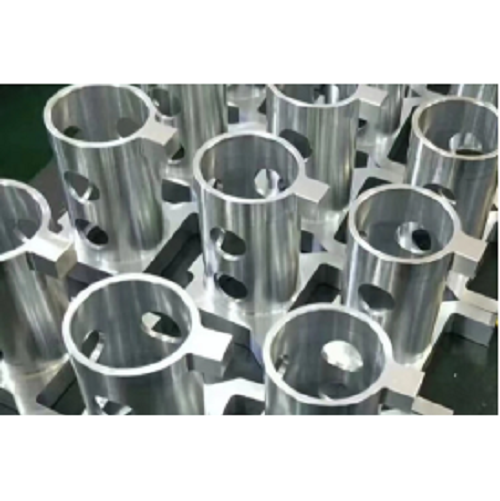

Falcon, as a aluminum die castings manufacturers, excels in aluminum die casting services, offering a comprehensive solution for precise and efficient production. Our state-of-the-art facilities utilize advanced technology to transform raw aluminum into intricate, high-quality components. With a commitment to excellence, Falcon's experienced team ensures optimal results in every casting project. Whether for automotive, aerospace, or consumer electronics, our aluminum low pressure die castingservices deliver components with superior strength, durability, and dimensional accuracy. From prototyping to mass production, Falcon,the aluminum die casting supplier, combines precision and innovation to meet diverse industry demands, providing a reliable and cost-effective solution for clients seeking top-tier automotive aluminum die castingservices.

The aluminum die casting process

Mold Preparation: The first step in aluminum die casting chinais preparing the mold, also known as the die. The mold consists of two halves, the cavity and the core, which are precisely machined to create the desired shape of the final part. The mold is then coated with a release agent to facilitate part ejection.

Molten Aluminum Injection: Once the mold is prepared, it is clamped together, and molten aluminum is injected into the cavity under high pressure. The aluminum is typically melted in a furnace and then transferred to a specialized die casting machine. The injection process ensures that the molten aluminum fills the entire cavity and takes the shape of the mold.

Solidification: After the molten aluminum is injected into the mold, it rapidly cools and solidifies. The cooling time depends on the size and complexity of the part. Cooling channels within the mold help to expedite the solidification process. Once the aluminum has solidified, it forms the shape of the desired part.

Part Ejection: Once the aluminum has solidified, the mold is opened, and the part is ejected from the mold. Ejection pins or ejector plates are used to push the part out of the mold. The part is then separated from any excess material, such as runners or gates, which are recycled for future use.

Trimming and Finishing: After the part is ejected, it may undergo additional trimming and finishing processes to remove any excess material, such as flash or burrs, and to achieve the desired final shape and surface finish. Trimming can be done manually or using automated equipment.

Surface Treatment: Depending on the application and requirements, the aluminum part may undergo various surface treatments, such as polishing, powder coating, anodizing, or painting. These treatments enhance the appearance, corrosion resistance, and functionality of the part.

For more information about custom precision machining, please feel free to contact us!

在线联系供应商

Other supplier products

| Aluminium Milling Service | Aluminium Milling Service Falcon offers a premier custom aluminum millingservice, utilizing state-of-the-art CNC technology for precision and effi... | |

| Aluminium CNC Machining | Falcon excels in aluminum cnc machining parts, providing a top-tier solution for precise and efficient production of aluminum components. Leveragin... | |

| Aluminum Machining | Experience excellence in CNC 7075 aluminum machiningwith Falcon MFG. Our specialized services bring precision to the forefront, crafting intricate ... | |

| Automotive Machining | Precision Automotive machiningis a crucial facet of vehicle manufacturing, involving precision processes to refine various components. Falcon autom... | |

| Aluminum Die Casting | what is aluminum die casting Falcon, as a aluminum die castings manufacturers, excels in aluminum die casting services, offering a comprehensive s... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |