Ultrasonic Spray Coating System

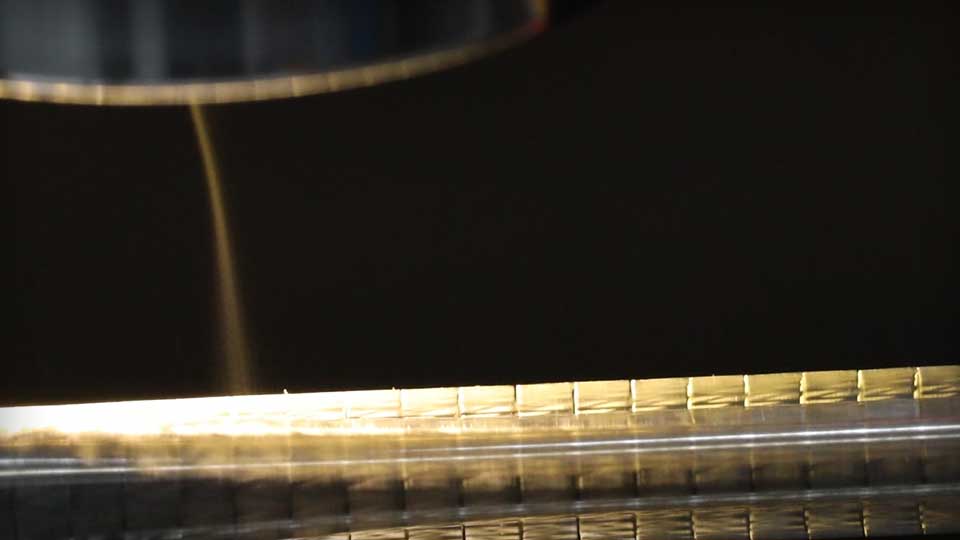

High performance ultrasonic spray coating system which includes ultrasonic spray nozzles, ultrasonic generator, liquid delivery system, automatic motion system, heating system, exhaust system, etc. is an equipment for ultrasonic spray deposition of homogenous, durable, repeatable thin film coatings. Compared with vapor deposition and sputter depostion, ultrasonic coating can significantly reduce the intial investment on the facility cost. Compared with conventional spray coating using air nozzles, non-clogging ultrasonic nozzle high performance technology dramatically decreases the comsuption of raw materials as well as the maintenance cost.

Ultrasonic Spray Coating System Benefits

Up to 80% reduction in raw material consumption with reduced overspray and splashing.

Uniform atomized droplets deposit homogeneous coating layers.

Precise spray patterns are easily shaped for a variety of applications.

Highly controllable flow rate provides greater repeatability.

Non-clogging ultrasonic spray nozzle reduces maintenance cost and downtime.

Ultra-low flow rate capabilities, intermittent or continuous.

Ultrasonic vibrations continuously disperse the particles to avoid suspensions agglomerating.

Capable of coating with very small minimum liquid volume. Optimal for R&D scale.

High corrosive resistance.

How Ultrasonic Spray Coating Systems Work

It is a unique spray coating process using ultrasonic atomization technology. The raw material to be coated is firstly prepared into solution or suspension. The solution or suspension is uniformly atomized into fine droplets in micron scale through an ultrasonic atomizer called ultrasonic spray nozzle. Droplets deposit onto the surface of the substrate by carrier gas in a controllable flow rate, so as to form a coating layer. The ultrasonic spray deposition amount can be precisely controlled by controlling of the flow rate of the solution or suspension using liquid feeding system, which results in the coating thickness is highly controllable.

The typical coating thickness of ultrasonic spray coating machine technique is from tens of nanometers to tens of microns. The liquid feeding system is usually a precision metering pump such as syringe pump, micro gear pump, etc. The ultrasonic spray nozzle which is the core of ultrasonic coating systemis fixed on an automatic motion system such as XYZ 3-axis robot arm or 6-axis robot arm to realize a scanning onto the 2-dimension or 3-dimension substrate, consequently a uniform thin film layer is coated on the substrate surface. Alternatively, one fixed nozzle array consisting of some ultrasonic nozzles spraying onto moving substrates is another typical type of ultrasonic spray coating system for volume production or the application of large area coating process.

Siansonic ultrasonic coating systems such as the benchtop coating system have already been used for various of applications in different industries such as implantable medical devices, fuel cells, solar cells, semiconductors, microfluidic chips, glass, etc. which are demonstrated in the video as below.

How Do Ultrasonic Spray Coating System Work?

An ultrasonic spray coating system, also known as a high performance ultrasonic coating machine, uses high-frequency vibrations to atomize liquid into tiny droplets that are then propelled onto a surface to create a uniform coating. The system typically consists of a liquid reservoir, an ultrasonic transducer, and a spray nozzle. The liquid is pumped into the reservoir, where the ultrasonic transducer vibrates at a frequency that creates pressure waves that break up the liquid into tiny droplets. The droplets are then propelled out of the nozzle by a gas, such as air or nitrogen, and onto the target surface. The ultrasonic coating system offers high precision and uniformity in coating thickness, making it suitable for a range of applications in industries such as electronics, medical devices, and automotive.

在线联系供应商

Other supplier products

| PZT Piezoelectric Ceramic Transducer For Sale | PZT piezoelectric ceramics from Siansonic ceramic transducer manufacturer, can be made in various shapes and sizes from 1mm to 200mm. We also provi... | |

| Ultrasonic Spray Pyrolysis Nozzle | The ultrasonic spray pyrolysis nozzle is a specific ultrasonic spray nozzle for ultrasonic spray pyrolysis to prepare ultra-fine powder. It has sel... | |

| Siansonic Nano Aerosol Generator For Disinfection | NX series nano aerosol generator is an ultra-fine atomization device specially used for ultrasonic atomization disinfection. Using high-frequency u... | |

| Ultrasonic Spray Nozzles | Ultrasonic nozzles, also known as ultrasonic spray nozzle or ultrasonic spray gun, is an ultrasonic atomization device based on the principle of La... | |

| Ultrasonic Spray Pyrolysis | R&D-scale Ultrasonic Spray PyrolysisSystem Spray pyrolysissystem for fine powder preparation in R&D scale Ultrasonic atomization techno... |

Same products

| mud pump | 卖方: 819146 | Mud pump (Mud Pump) is also a popular concept of a broad pump. Different regions and habits will ... | |

| Ultrasonic Spray Coating System | 卖方: Siansonic Technology Ltd | High performance ultrasonic spray coating system which includes ultrasonic spray nozzles, ultraso... | |

| Siansonic Benchtop Ultrasonic Coating System | 卖方: Siansonic Technology Ltd | Benchtop ultrasonic spray coatingsystem is able to equip with almost all of series of Siansonic m... | |

| Siansonic Batch Type Megasonic Plate | 卖方: Siansonic Technology Ltd | Megasonic transducer cleaning uses higher frequency ultrasonic energy in mega hertz scale to boos... | |

| Siansonic Balloon Catheter Coating System | 卖方: Siansonic Technology Ltd | The balloon catheter coating system is an ultrasonic coating systemspecially used for depoisting ... |