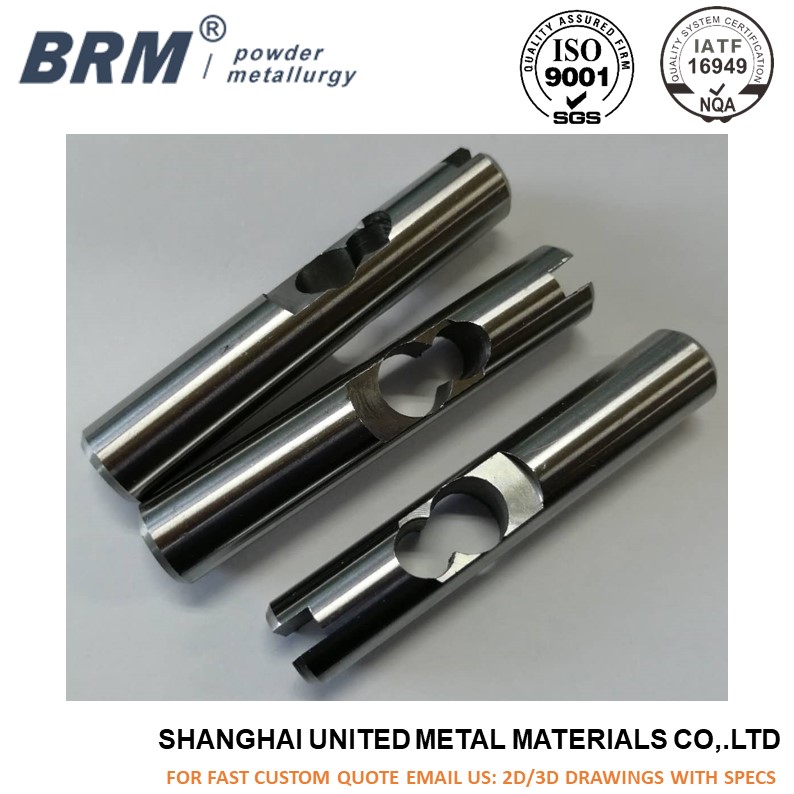

MIM4140 steel selector button with blackening surface treatment

Product Specifications /Features :

Feedstock– Injection molding – De-binding – Sintering –Finished parts

MIM is a advanced metalforming technology for the following requirement:

1. small part with complex shapes

2. high density

3. precision tolerance

4. high performance of tensile strength, elongation, hardness

5. low cost : minimal secondary machining cost

Advantage:

1. First Article Inspection report

2. Only qualified parts would be packed & shipped

3. Inspection reports are kept for one year at least

4. Cost improvement review is done every year

Why Choose BRM

1. Over 20 years experience of metal injection molding

2. Certification of IATF16949, ISO9001, SGS, RoHS etc.

3. 5000m² factory area with Daily output over 2000000pcs

4.One-stop serive of Designing, Manufacturing and Finishing

5. Tooling 25 days, Sampling15 days.

BRM metal injection molding specializes in Powder Metallurgy for all industries with more than 20 years. We have helped thousand of our customers with one-stop service from Designing, Manufacturing &Finishing by use of different metalworking process like

Metal injection molding

PM (press sintered)

Precision casting

CNC &Machining

Certification IAFT16949, SGS, RoHS, ISO9001, ISO14001 and ISO18001. Also inspection report before delivery will be forwarded to control the quality.

Applicable materials we can do include stainless steel, low alloy steel, tool steel, tungsten alloy, soft magnetic alloy and so on. Our mim products can apply in many fileds especially Military, Automotive, 3C consumer electronics, Medical, Tools and Machinery.

在线联系供应商

Other supplier products

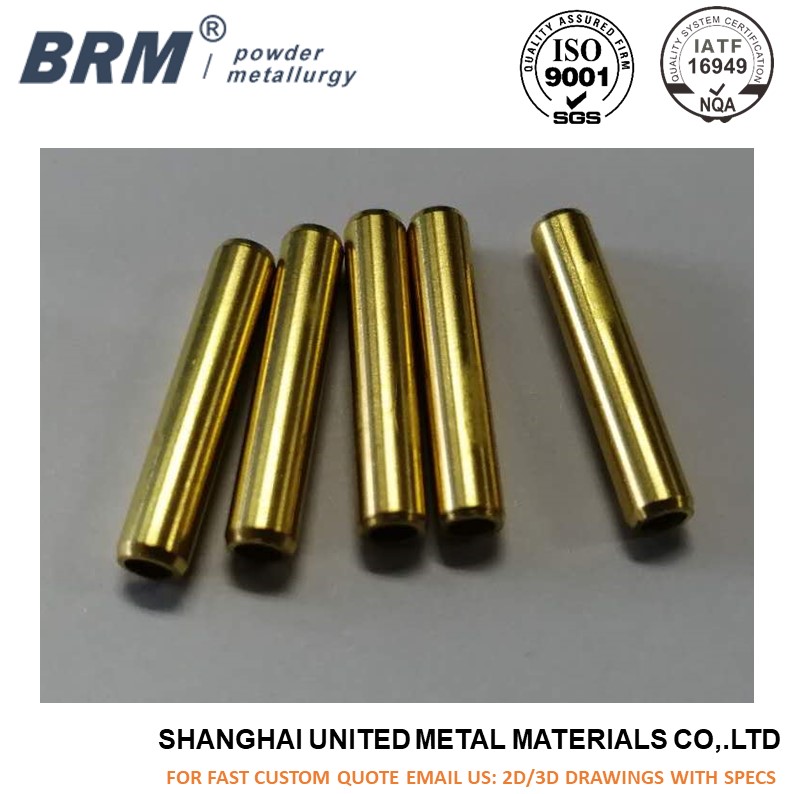

| Machining automotive brass tube factory direct supply | Product Specifications /Features : Feedstock– Injection molding – De-binding – Sintering –Finished parts MIM is a advanced... | |

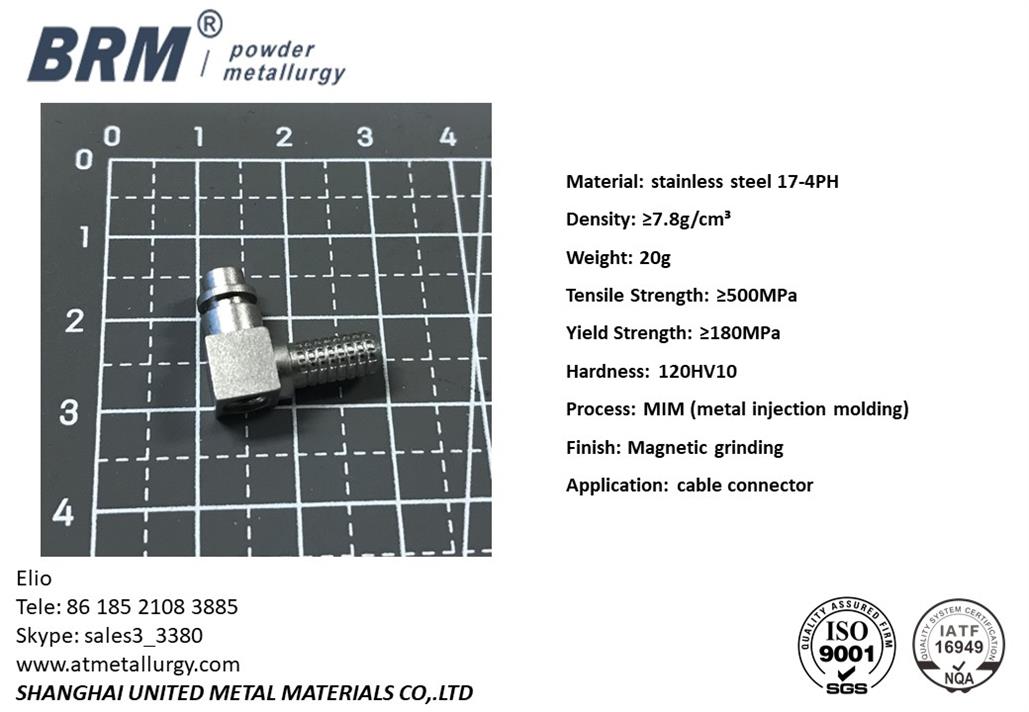

| MIM Stainless Steel Metal 17-4ph AISI 630 cable connector | Why Choose BRM 1. Over 20 years experience of metal injection molding 2. Certification of IATF16949, ISO9001, SGS, RoHS etc. 3. 5000m² factor... | |

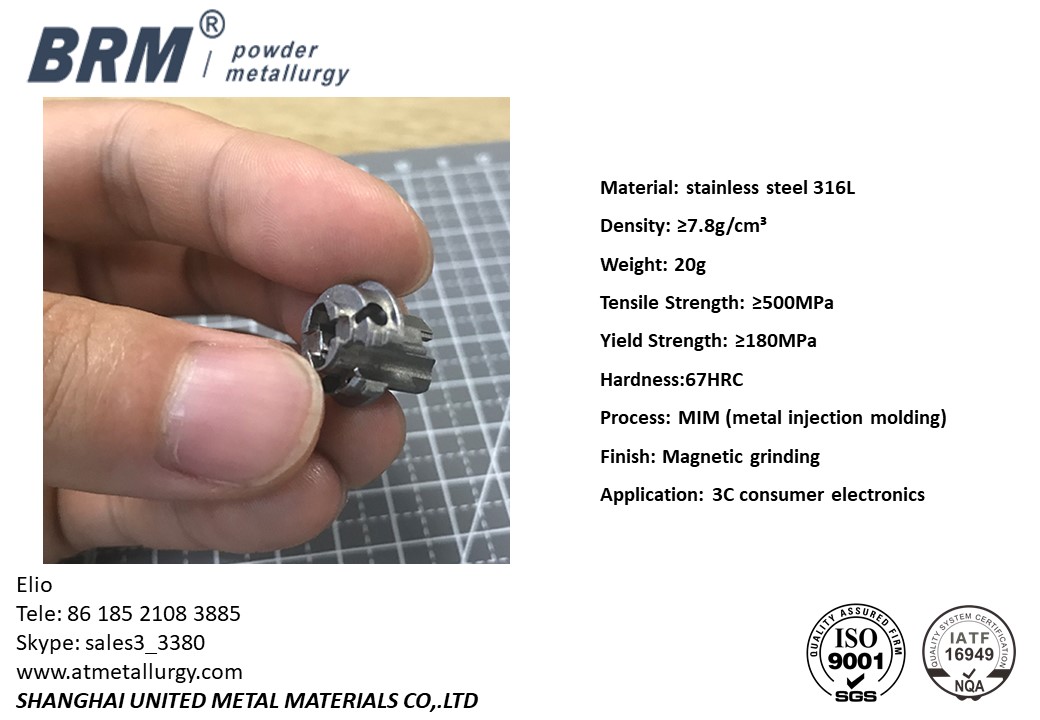

| MIM Sintered Headphone Metal Button | Product Specifications /Features : Feedstock– Injection molding – De-binding – Sintering –Finished parts MIM is a advance... | |

| MIM Sintered SUS 304 Sensor Socket | Product Specifications /Features : Feedstock– Injection molding – De-binding – Sintering –Finished parts MIM is a advanced... | |

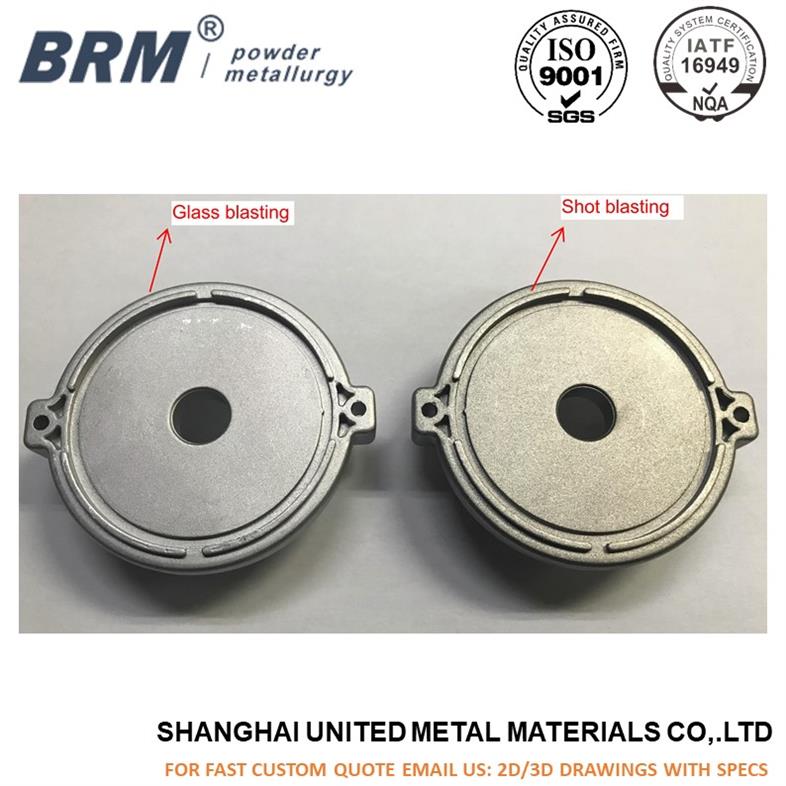

| Casting A360 automotive parts with shot blasting | Product Specifications /Features : Feedstock– Injection molding – De-binding – Sintering –Finished parts MIM is a advanced... |

Same products

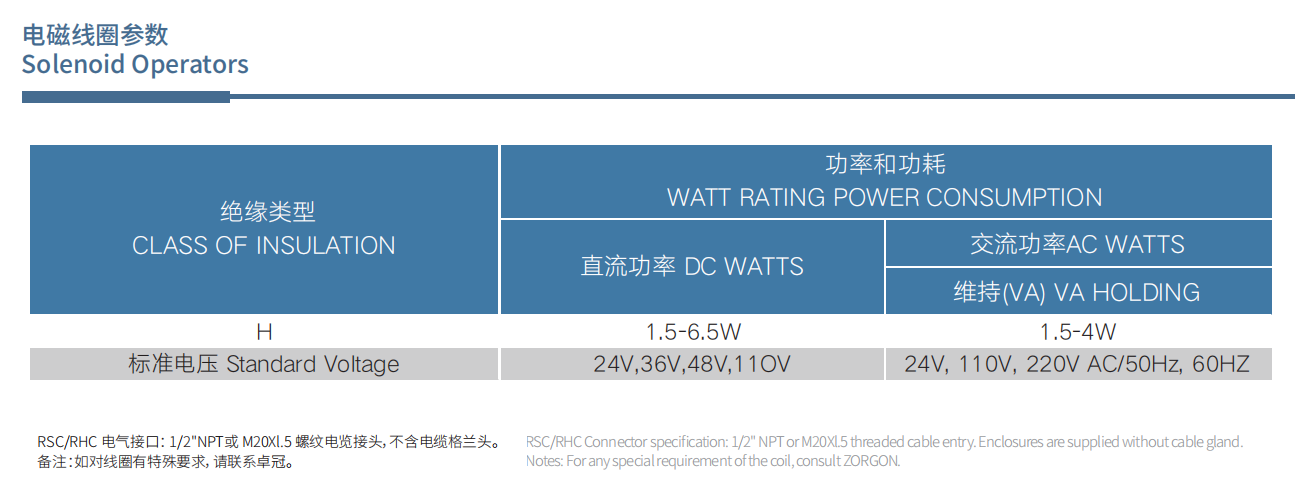

| 151系列电磁阀 | 卖方: 卓冠 | 151系列电磁阀,在流程生产中电磁阀很多时候是与气动调节阀和活塞执行机构配合使用,这时电磁阀只起辅助功能 但作用十分重要。尤其是在工艺生产连锁中,电磁阀具有很重要的作用,如气源有故障时工艺阀的开... | |

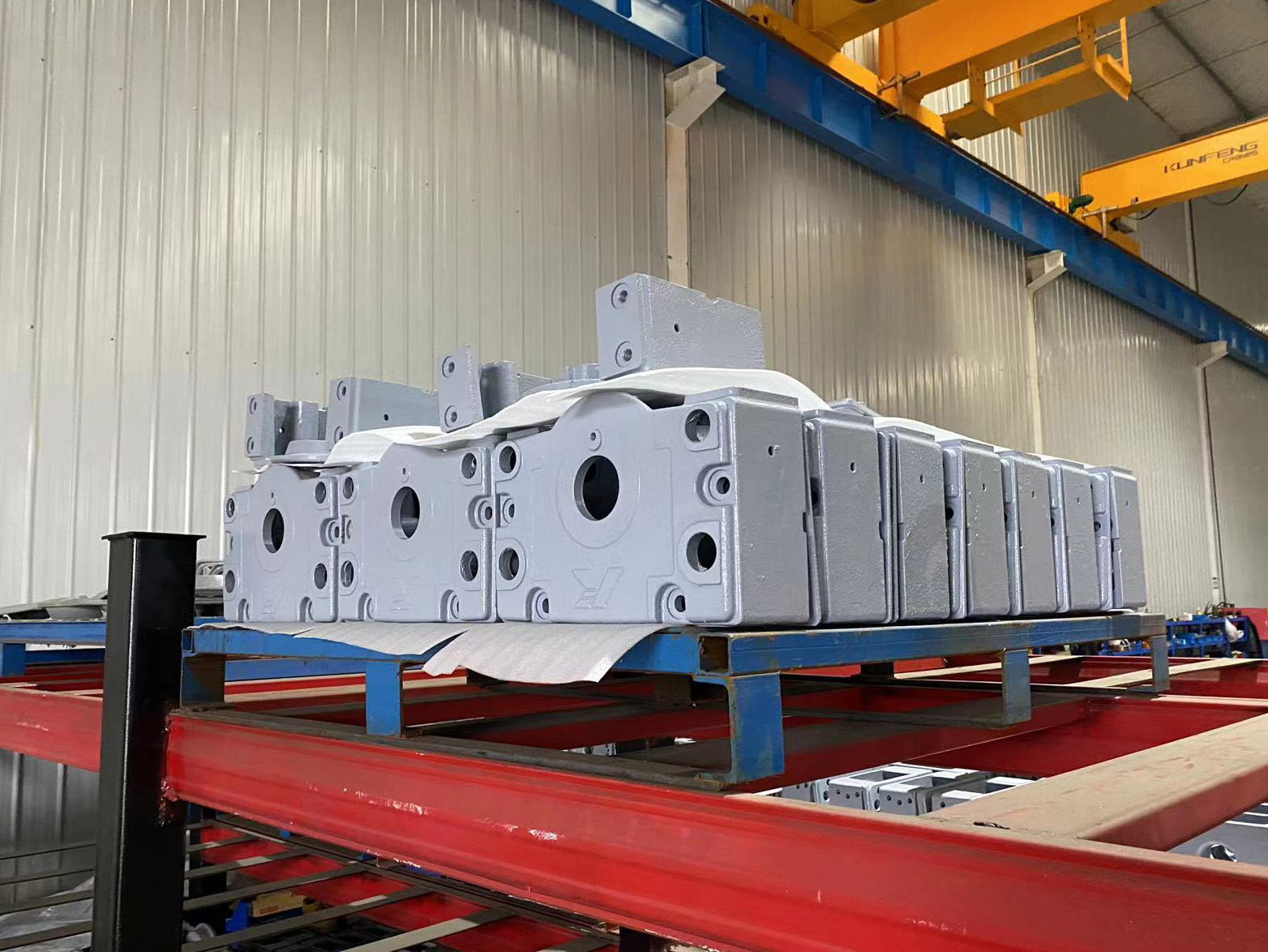

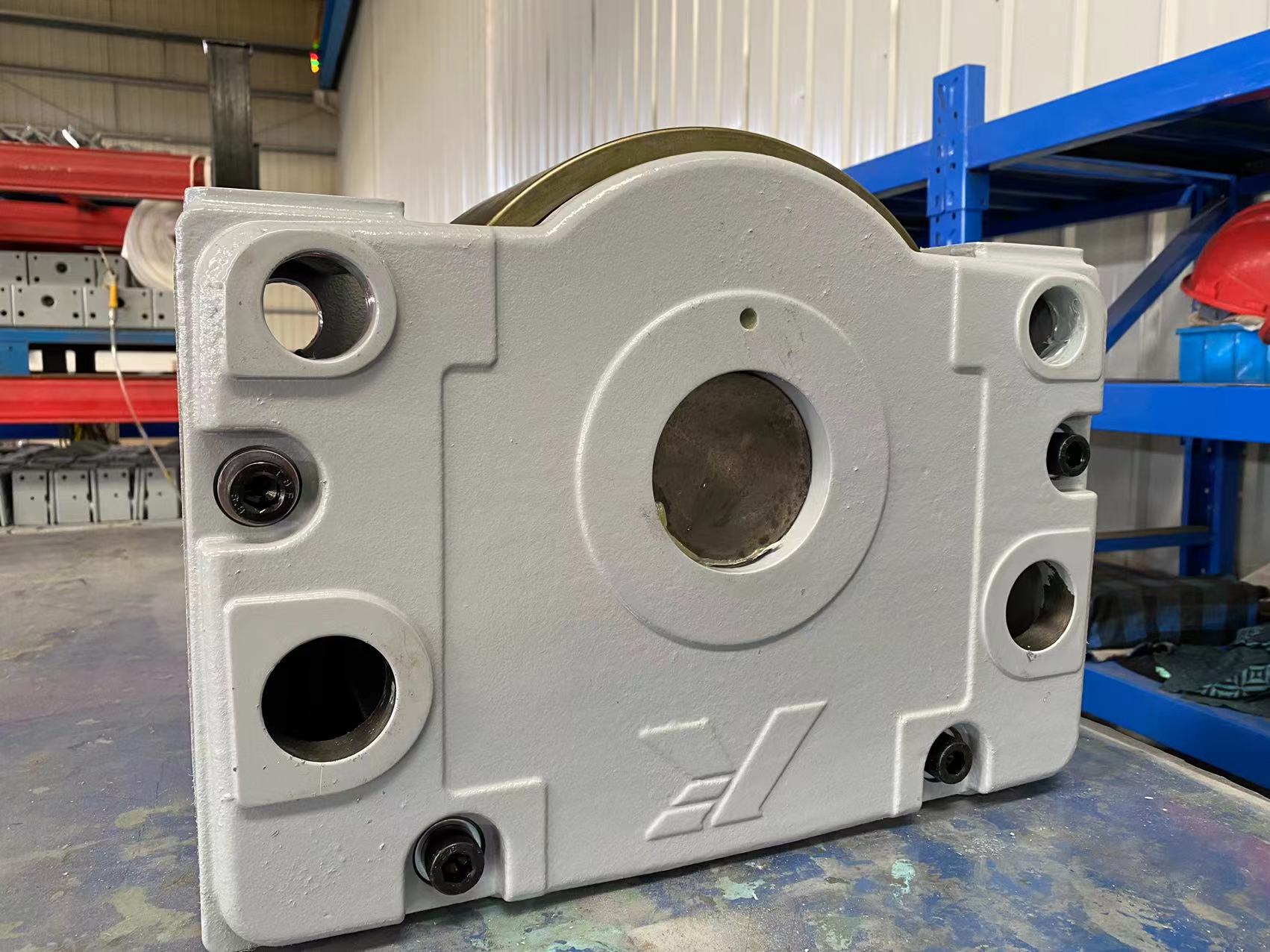

| Wheel Block Drive System with Gear Motor for Crane | 卖方: 昆峰重工(苏州)有限公司(KFCRANE) | A complete driven wheel system includes the wheels, electric AC induction brake motor, gearbox, e... | |

| DRSA Wheel Block System | 卖方: 昆峰重工(苏州)有限公司(KFCRANE) | KUNFENG® DRSA 轮组系统具有负载能力大、尺寸紧凑、轮径大的特点,确保为相应的应用选择合适的单元。 特征: • 优质可靠的服务 • 应用多样性:用于移动桥梁... | |

| CNC machining precision steel parts | 卖方: 上海秉瑞金属材料有限公司 | BRM metal injection molding specializes in Powder Metallurgy for all industries with more than 20... | |

| Precision CNC machining platen of rotor for automotive transmission parts | 卖方: 上海秉瑞金属材料有限公司 | Product Specifications /Features : Feedstock– Injection molding – De-binding – ... |