Chemical Coater

Chemical coater used for processing strip surface of continue hot galvanizing line, coating the solution as Chromium-free six solution, chromium free solution, organic coating, anti-fingerprint solution, to improve strip corrosion resistance ability.

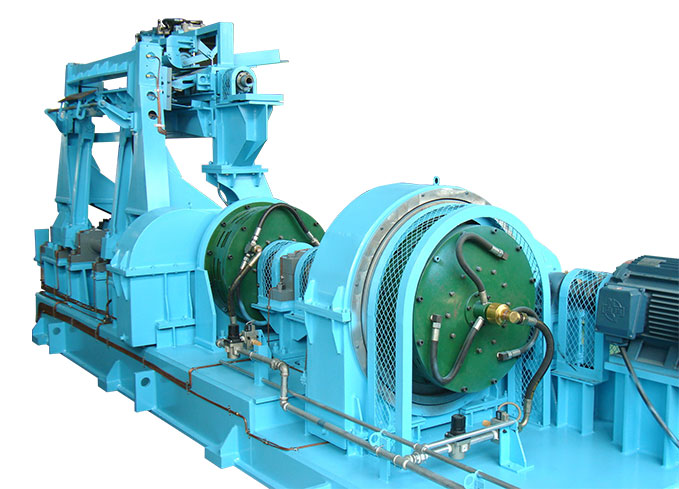

Introduction of Chemical Coater

BOYA equipment chemical coating machine is designed to work in conjunction with strip pretreatment equipment to significantly reduce the amount of chemical waste generated during the coating process. In addition, the bottom head can be rolled out from under the strip to facilitate maintenance and replacement of rolls.

After surface be treated strip enters into roll coaters head working area through stable roll under frame. Hydraulic cylinder push applicator roll stand close to and snap to strip, adjustment mechanism micro adjust the insert valve between applicator roll and strip for control the coating layer thickness. Solution supply system sends the paint to tray, VVVF drives pick up roll to pick painting and stick to applicator roll, Applicator roll coats the painting to strip surface, it's can one surface painting and two surface painting.

Application Scope of Chemical Coater

Material Strip thickness Strip Width Leveling Speed

Steel plate 0.2-2.0mm 700-1550mm ≤150m/min

Structure Advantage of Chemical Coater

According to the process requirements, it can be equipped with two bodies, one for use and one for backup, to realize the rapid switching of continuous units offline without stopping, to meet the requirements of variety switching and equipment maintenance.

The body of the roller coater can be equipped with two-roller or three-roller coating according to process requirements.

The roller coater is equipped with an automatic or manual roller gap adjustment mechanism, and is equipped with a pressure sensor, which can effectively control the thickness of the paint film.

The equipment is equipped with a quick roll changing device and a safety protection device to ensure rapid roll change under the premise of safe operation.

Electromechanical and hydraulic control integrated products, equipped with reliable Siemens control system and optimized process adjustment template, can effectively ensure stable product quality.

We can also offer kinds of coil coaters for sale, if you have needs, please contact us.

Other supplier products

|

|

Rotary Shear for Annealing and Galvanizing Line |

In order to ensure that the tearing surface of the strip is smooth, it is necessary to ensure that the upper and lower knife planes are relatively ... |

|

|

Scale Breaker |

Scale-breaking tension leveller, also called scale breaker, is generally used for continuous pickling units. Scale breaker machine applies to bend ... |

|

|

Tension Leveler for Galvanizing Line |

Galvanizing line tension levelleris a continuous stretching bending straightening machine that is used in the continuous hot-dip galvanizing line. ... |

|

|

Work Roll |

BOYA produces slender rolls such as smooth roll (can be chromed), spiral roll (can be chromed), and concave roll. There are more than 10 kinds of r... |

|

|

Scrap Baller |

The scrap balleris an excellent choice for us to dispose of waste materials. It rolls the cut edges into a ball and recycles them, and sorts the cu... |

供应产品

Same products