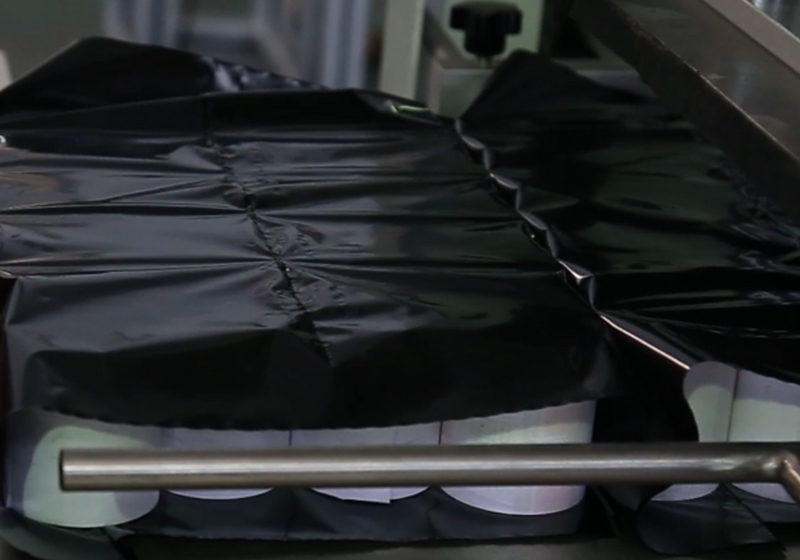

GPPE Construction Paper Semi-automatic Surface Rewinder

Description

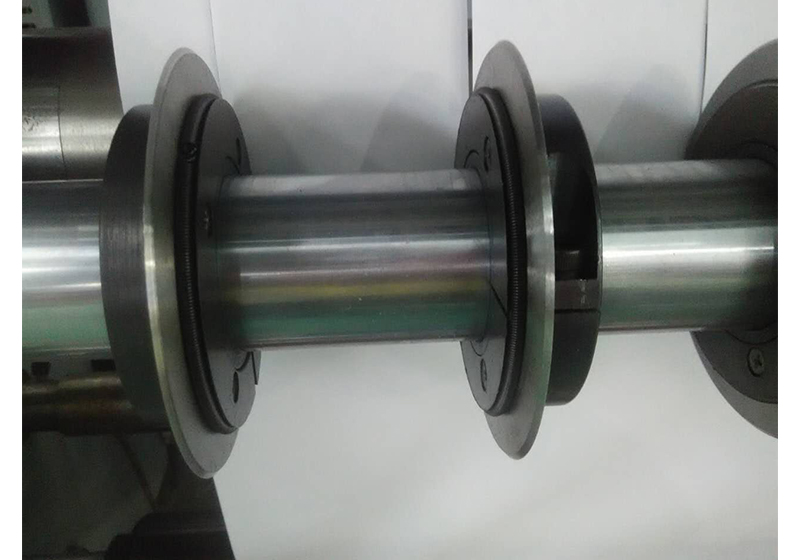

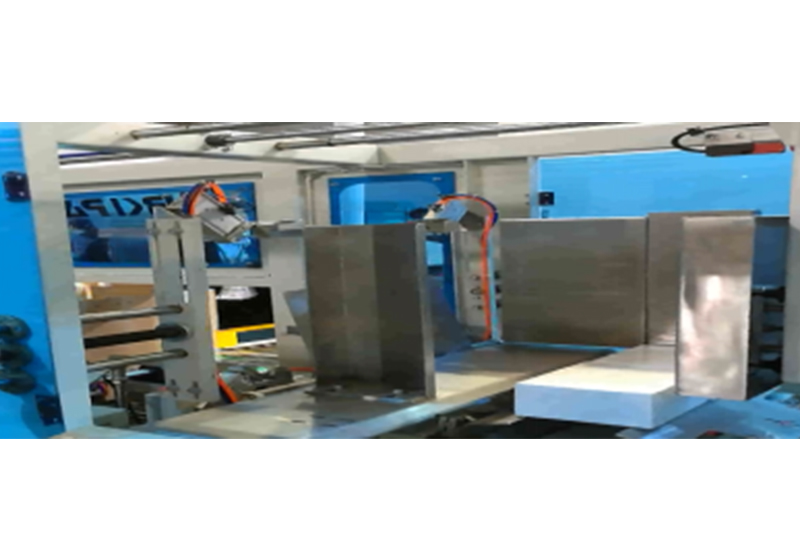

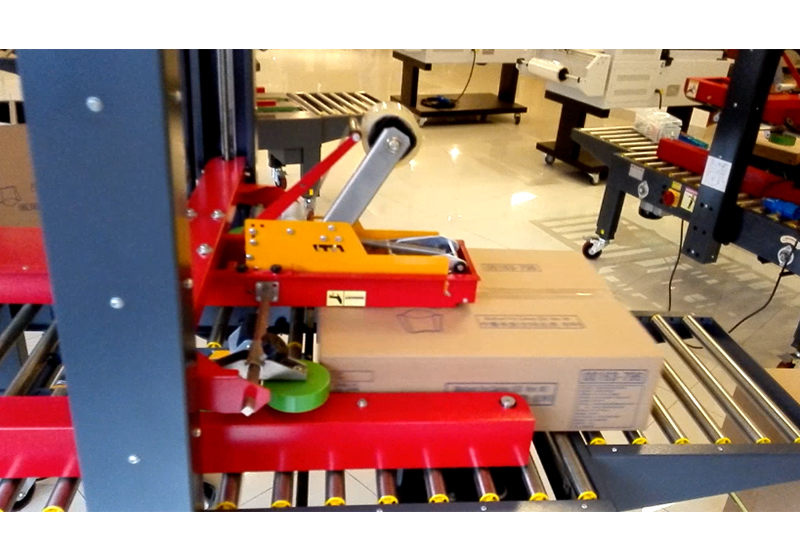

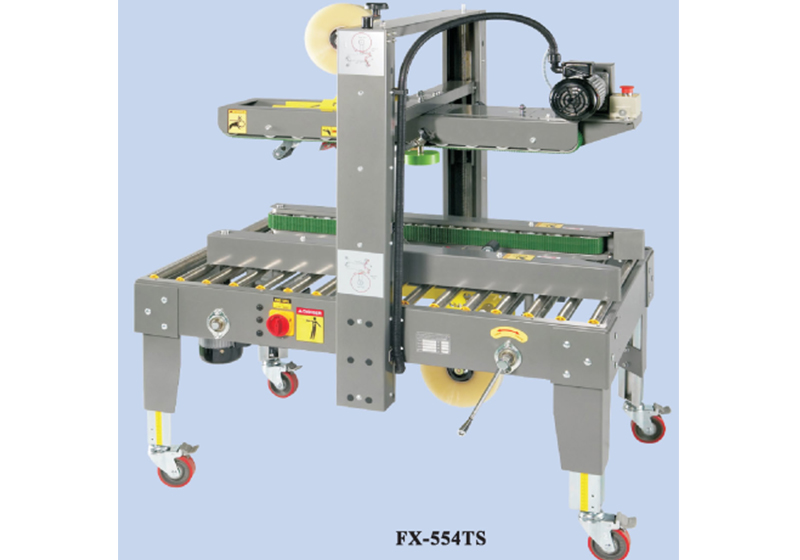

Operator Responsibilities Each Cycle The operator is responsible for loading cores with core loader onto a rewind mandrel and placing the mandrel into the rewinding station. Rest of the process will be carried out by the semi-automatic surface rewinder. Automation As long as mandrels are staged in the autoloader, this surface rewinding machine will insert the cored mandrel in the rewinding station, cut the tails, wrap the tails around the cores, tuck the tails, wind the rolls to the desired length, transfer the rolls to the sealing station, seal the tails of the finished rolls, remove the mandrel cap from the mandrel and transfer the finished rolls to a packing table. This surface rewinding machine dictates the cycle time, not the operator. Standard Features(in addition to the previously identified GPPE features) 1. Automatic mandrel insertion system. 2. Automatic tail cutter. 3. Automatic gluing system (optional tabbing unit is available). 4. Automatic roll removal system with conveyor to transfer rolls to the integrated packing table. 5. This semi-automatic surface rewinder can be upgraded to 2-ply configurations. Optional Features Flexographicprinting: It is used for online printing when slitting rolls, paper accumulation buffer keeps the printing nonstop during the cycles gap, up to 4 color on-line printing. Double web system By adding an additional unwind stand and the dual web package, the operator can load two narrow width master rolls into this semi-automatic surface rewinder and process both rolls simultaneously. This allows the operator to maximize slitting efficiency when processing long runs of narrow width master rolls.

Critical Specifications

|

Maximum Web Speed (1-Ply) |

2300fpm (300mpm) |

|

Maximum Web Speed (2-Ply, optional) |

1200fpm (120mpm) |

|

Maximum Web Width |

54inches (1100mm) |

|

Maximum Unwind Roll Diameter |

50inches (1270mm) |

|

Maximum Unwind Roll Weight |

3303lbs (1500kg) |

|

Minimum Rewind Diameter (option for 1.18inches (30mm) is available) |

|

|

Maximum Rewind Diameter |

12inches (200mm) |

|

Minimum Rewind Core O.D. |

|

|

Maximum Rewind Core O.D. |

1inches (25. mm) |

在线联系供应商

Other supplier products

| GPPE Construction Paper Semi-automatic Surface Rewinder | Description Operator Responsibilities Each Cycle The operator is responsible for loading cores with core loader onto a rewind mandrel and plac... | |

| Boarding Pass Paper Automatic Palletizing Machine | Description Downsize your case packing and palletizing areas with a compact case packer and palletizing system. Our automatic palletizing machin... | |

| Label Stock Automatic Palletizing Machine | Description Downsize your case packing and palletizing areas with a compact case packer and palletizing system. Our automatic palletizing mach... | |

| GPPE Label Stock Roll Off-line Die Cutting Machine | Description Because of the high volume of rolls produced on GPPE’s rewinders, a roll processing line is offered to minimize downstream lab... | |

| Lottery Paper Sleeve Wrapper | Standard Specifications(custom sizes are available) Maximum Processing Speed 20 cycles (rows) per minute Minimum Roll Diam... |

Same products

| Full-automatic Spring Packaging Machine ZF-TH700 | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | 卖方: 杭州四色印科技有限公司 | ||

| Sticker equipment | 卖方: 杭州四色印科技有限公司 | Supply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifunct... |