Automatic Lube Oil Filling Machine motor oil Filling Machine

Automatic Lube Oil Filling Machinemotor oil Filling Machine

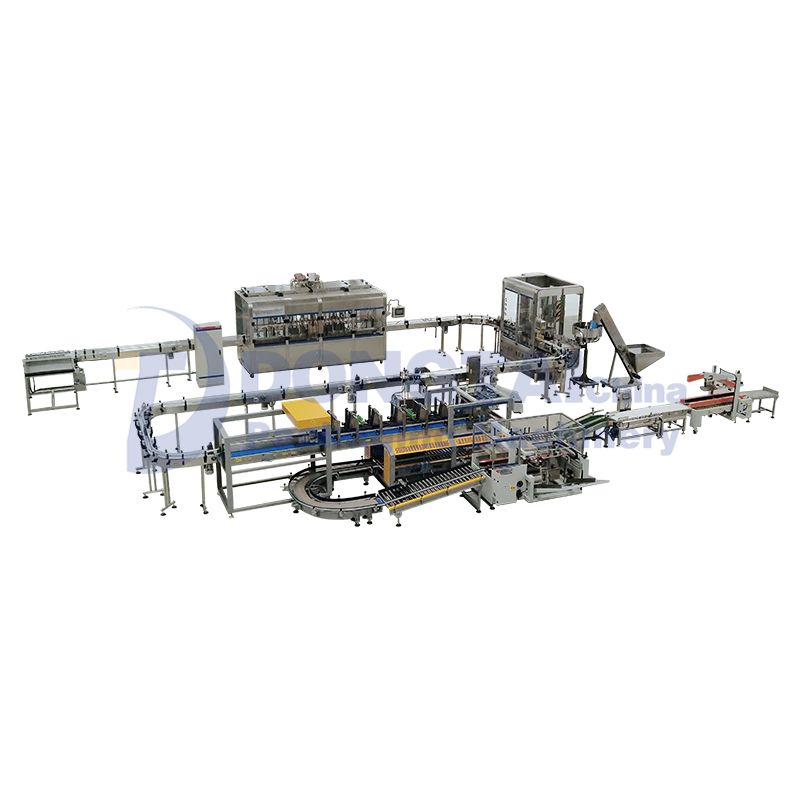

The filling line equipment has the characteristics of stable, easy operation, high cost performance and high automation. Compared with the same kind of product, it has a longer service life, a complete set of ability, and a reasonable design of the whole line. Equipped with coordinated photoelectric and whole line interlocking devices, the whole line needs only 2-4 workers for operating. The technology used is the leading level in today's industry. The whole line of filling equipment meets the needs of production, unmanned and integrated production.

Engine Oil Filling Machine Specifications:

|

Filling nozzles |

8 |

|

Filling speed |

1500-2000 (barrels / hour) |

|

Filling capacity |

1-5L |

|

Filling accuarcy |

± ≤ 0.1% FS |

|

Power Supply |

220/380V3 phase +Earth Wire, 50 Hz |

|

Number of workers |

3-5 people |

|

Whole line consumption |

about 100L/Min |

|

The equipment noise |

less than 50D |

Main Technical Parameters:

The machine is suitable for sorting and feeding of various plastic buckets, and has stable performance. It can be used together with the automatic packaging line to save labor and increase production efficiency. Put the whole barrel flat on the platform, and push the rod automatically to push the belt into the barrel. Orderly, do not hurt the barrel. It is composed of PLC control electric part, photoelectric sensor and frequency conversion governor. It has high integration level, strong control ability, reliable operation and can be controlled in conjunction with filling equipment.

- Automatic filling machine

This machine is a flow meter filling machinewith high filling accuracy. It applies to 1-5L liquid for filling.It uses filling bulkhead of preventing leaking and wire drawing, filling up and down system of preventing high foam products, assuring the lip orientation and automatic control system. The tank controls material level automatically ,feeding the material is also automatic.The tank adopts the pressurized design that will improve the speed of the blanking. Combine with the mechanotronics protecting device, if the machine has any abnormal information ,it will stop and alarm automatically. The touch screen will appear the detail parts which is abnormal. It is produced with the GMP standards, safety, environmental , hygienism, beautiful and adapt to different kinds of work place.

machine adopt tracking apparatus and private servo displacement system , includes cap sorting, hanging and capping in one unit, capping head and bottle running synchronous, capping heads adopts servo controlled torsion capping, no harm to bottles and caps. Whole machine advanced structure, smooth operation, low noise, wide range of application, high production speed.PLC memory formula, one key call parameter, External frame of security protection. Automatic lubrication function long life time.

Features:

Type of Equipment: automatic on-line high-speed sealing machine

Control System: transistors modular digital integrated circuit control ground

Cooling System: Dual fan, double radiator water cooling system forced circulation

sealing effect: the seal intact, one hundred percent. Even a small amount of liquid bottle leaving traces, does not affect the sealing effect.

Introduction:

This machine is widely used in food, toys, daily chemical, electronics, medicine, metal, plastic, printing and other industries; such as flat shampoo bottles, flat medicine bottles and so on. It adopts standard PLC, touch screen, standard sensor electronic control system, human-computer interface in Chinese and English notes and improve the function of fault tips, operational guidance functions, troubleshooting instructions; easy to use and easy maintenance; no product non-labeling, non-sticker auto-correction and automatic detection function. It can be also matched with batch coder or printer coder function.

The machine is new type of automated packaging equipment,reached and designed on the basis of foreign advanced technology. The machine has distinctive features compared with the similar packaging way. The vast majority of regular bottled, boxed, block and other products, widely use corrugated carton packaging in the present domestic production, has been accepted by the public.It can finish at one time, reduce the cost of equipment and the space of equipment and raw materials and all levels of transportation contradiction. The appearance of the packaging is beautiful and smooth; It is tight and firm after wrapping. Application of unpacking-packing-sealing integrated machine, reduce labor intensity, labor resources and production process, will upgrade the traditional packaging way and the inevitable trend of development.

DONGTAIcan provide a wide variety of filling machine such as liquid filling machine, sauce filling machine, powder filling machine and granule filling machine. Our products have high quality and competitive prices. If you are interested in our products, please click here.

在线联系供应商

Other supplier products

| Semi Automatic Filling And Sealing Machine | Semi Automatic Filling And Sealing Machine DTG-40 semi auto aluminum tube filling and sealing machineis specially design to fill all kinds of liqui... | |

| Magnetic Pump Liquid Filling Machine Liquid Filling Machine Peristaltic Pump Filling Machine | Magnetic Pump Liquid Filling Machine Liquid Filling MachinePeristaltic Pump Filling Machine Characteristic: Our magnetic pump liquid filling machin... | |

| Automatic Plastic Ampoule Bottling Blow Fill Seal Machine Pharmaceutical Oral Liquid Filling Packing Machine | Automatic Plastic Ampoule Bottling Blow Fill Seal Machine Pharmaceutical Oral Liquid Filling Packing Machine This machine is a kind of compact type... | |

| Cooking Oil Filling Machine Automatic weighing edible oil filling machine Cooking Oil Filling Machine supplier | Cooking Oil Filling Machine Automatic weighing edible oil filling machineCooking Oil Filling Machine supplier Single-head single-pump single-freque... | |

| Automatic weighing edible oil filling machine Automatic Liquid Filling Machine | Automatic weighing edible oil filling machine Automatic Liquid Filling Machine Automatic weighing edible oil filling machineis suitable for filling... |

Same products

| Full-automatic Spring Packaging Machine ZF-TH700 | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | 卖方: 杭州四色印科技有限公司 | ||

| Sticker equipment | 卖方: 杭州四色印科技有限公司 | Supply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifunct... |