Custom Contract Molding

ISO Class 8 Clean Room

Quality Control

Low & High Volume Manufacturing

Competitive Price

Reliability and Stability

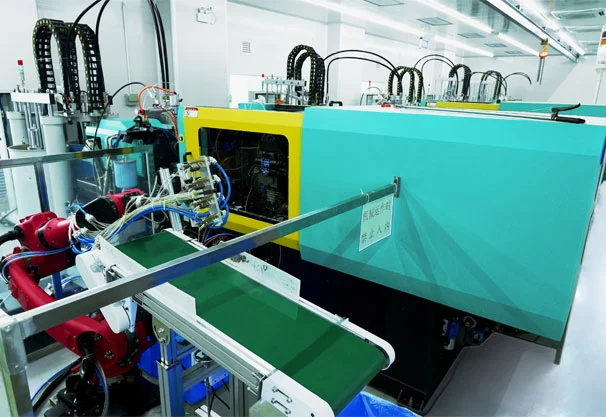

Packson is the OEM plastic mould suppliers. We can supply custom injection moldingparts. Our high quality and precision injection molding processes assist us to make molded parts from big, small to medium-sized components with good quality. We are able to meet all plastic part requirements according to materials, sizes, shapes, tolerances, and so on. We offer various services to OEM customers with manual, semi-automated, or fully automated assembly lines.

There are more than 40 injection molding from 60 tons to 1000 tons at Packson., which helps us to handle a wide range of parts from a small run of prototype samples with 500 shots to a production run of high volume parts with over one million.

Our engineering department works closely with our customers for assuring that high-quality parts will get into the market in time. We work for all kinds of industries such as OEM, automotive, agriculture, electronic appliance, and construction.

So contact Packson to get the best custom injection molding services of OEMs in plastic injection molding if you need them.

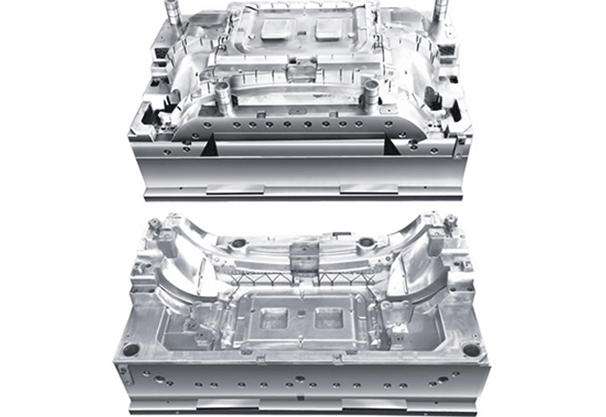

Custom Injection Molding Tool Design

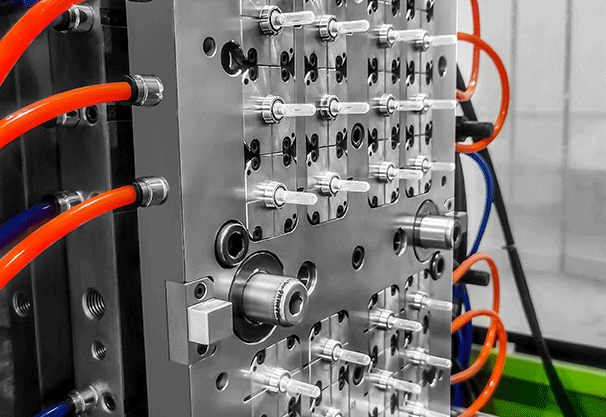

Injection Mold plays a pivotal role in injection molding. Whatever it's a simple part or a complicated part, the injection mould designis the most important part for high-quality and smoothly running injection molded parts.

The primary goal of injection mould design is for making high-quality molded parts and better running of mold during the molding process. Good tooling design provides belowing benefits:

-Save cost and time for tooling also molding

-Improve mold running during the molding process

-Make high-quality molded parts

Benefits & Capabilities of Custom Injection Mould Assembly Line

Equipped with the manual and semi-automatic assembly lines, we can help you finish secondary operations for your part like :

- Ultrasonic Welding

- Heat Staker

- Vacumm Sealer

The secondary operation is good of shorting supply chain, reducing cost and lead time:

- Assembly line help shorten the supply chain and decrease lead time

- One-site semi-automatic assembly line with robotics operation help to minimize labor cost

- One shop operation for in-house assembly facilities makes sure quality control before part delivery.

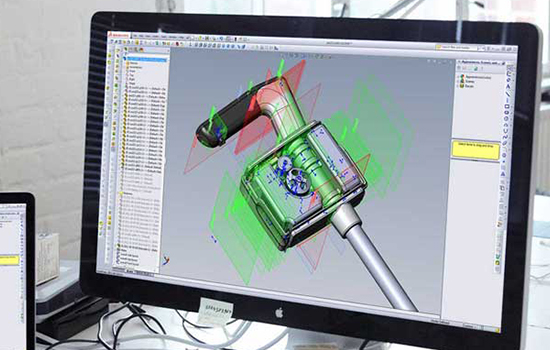

Custom Injection Molding Part Design

A bad design for your injection molded parts will cause a bad situation like losing time and money, but the good injection molding part design will make high-quality parts and save more time for great efficiency. Part design details and engineering play significant roles in injection molding. It helps us to make an optimized production solution, reduce costs, and provide good quality parts.

Keep eyes on the following points for better injection molding:

Types of Custom Injection Mould Methods at Your Service

For injection mold, it's not only for injection plastic material. It has another way to show the material. It's not the only way to make the parts.

2K Molding

A

The product is molded by 2 different plastic materials or 2 colors which is efficient and economical. The most obvious advantage for 2K molding is cost saving. There are 2 injection steps during injection molding. That's why we call it 2K injection molding. It allows two materials with different properties, colors, or levels of hardness to be injected into the molding machine and make the molded product.

Liquid Silicone Rubber Molding

A

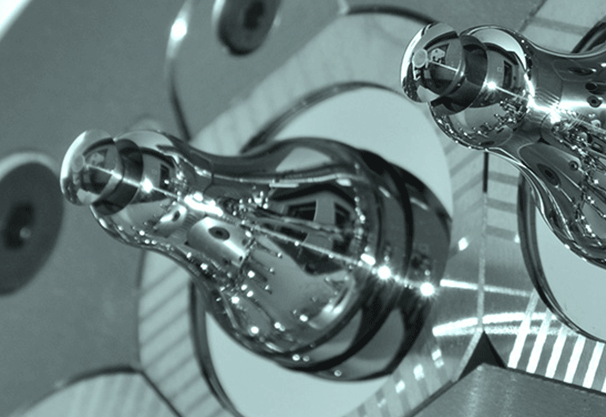

Because of the flexibility of LSR molding, there is a slight difference between LSR molding and plastic injection molding. The injection machine between them is also quite different. LSR molding uses liquid silicone material which is also different from solid silicone.LSR Mold is processed by a CNC machine and creates a high-temperature tool for molding.

Insert Molding

A

Inserting Molding is one of the molding ways for injection molding. It is used to encapsulate metal parts or components in a plastic part. There are two processing ways: First, the component or metal part will be placed into the mold before we start injection molding operation. Second, the part will be molded and the component will be locked into plastic when a melted plastic material is injected into the mold.

Material Selection of Custom Injection Mould

Different materials are used in various parts according to the specific requirements for the part. The material choosing also make an influence on tooling material. At Packson, we have been working with thousands of material suppliers for providing turkey material choosing solutions. But most of the time we choose the material according to customer's requirement and we will also give our suggestion for the material solution sometime. Here are common resins that we use but are not definitely limited as below:

- Commodity Resins

-ACRYLONITRILE BUTADIENE STYRENE (ABS)

-ACRYLIC (PMMA)

-HIGH-DENSITY POLYETHYLENE (HDPE)

-POLYPROPYLENE (PP)

-POLYETHYLENE (PE)

-POLYSTYRENE (PS)

-POLYVINYL CHLORIDE (PVC)

-STYRENE ACRYLONITRILE (SAN)

- Engineering Resins

-ACETAL (POM)

-POLYBUTYLENE TEREPHTHALATE (PBT)

-PBT / PET (GLASS-FILLED)

-POLYETHYLENE TEREPHTHALATE (PET)

-POLYCARBONATE (PC)

-POLYETHER ETHER KETONE (PEEK)

-POLYETHER IMIDE (PEI)

-POLYETHERSULFONE (PES) / POLYSULFONE (PSU)

-POLYETHYLENE ETHER (PPE)

-POLYAMIDE (NYLON)

-POLYAMIDE (NYLON) – GLASS FILLED

-POLYPHENYLENE SULFIDE (PPS)

-THERMOPLASTIC ELASTOMER (TPE)

-THERMOPLASTIC POLYURETHANE (TPE/TPU)

Custom Injection Mould Tool Design

Packson - Your Injection Moulding Manufacturer

Your Expert in Injection Molding

ISO Class 8 Clean Room

Equipped with clean room and certificated with ISO 13485 and ISO 9001, we are able to hanlde your medical OEMS production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Except long run production, we also can provide better solution for your low-volume production by prototyping tooling.

Competitive Price

Our good investments in euipments and QC system help us to get greater efficiency and higher quality which decrease reject ratio. All these make us send parts to you on time with competitive cost.

Reliability and Stability

Our 24 hours|3 shifts production system help your parts get into market quickly and steadily.

Related Injection Molding Services From Packson

在线联系供应商

Other supplier products

| Silicone Rubber Injection Molding | Packson's state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped with 14 sets of Liquid Silicone Rubber (LSR) injec... | |

| Custom Contract Molding | Packson is the OEMinjection mold maker china. We can supply custom injection molding parts. Our high quality and precision injection molding proces... | |

| Medical Plastic Injection Molding | medical plastic injection molding companies Packson is not totally the same as other medical plastic injection moldingcompanies. Because we are an... | |

| Clean Room Injection | ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability With more... | |

| Product Design & Development | In addition to providing moulding die designsolutions, we can also provide customers with product design optimization solutions to save more cost a... |

Same products

| JY-160S2 Standard Plastic Injection Machine | 卖方: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| Silicone Rubber Injection Molding | 卖方: Packson Mold Co.,Ltd | Packson's state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped ... | |

| Prototype Injection Mould | 卖方: Packson Mold Co.,Ltd | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CN... | |

| Precision Injection Molding | 卖方: Packson Mold Co.,Ltd | At Packson, we specialize in manufacturing custom precision mold partsand machined parts that mee... | |

| Overmolding Injection Molding | 卖方: Packson Mold Co.,Ltd | Overmoldingmold is made of overmolding injection molding processwhich is a special injection mold... |