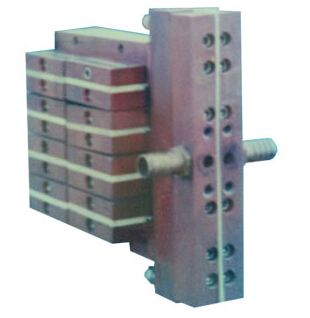

Double-station Dual Frequency Gear Ring Shaft Quenching Machine

供应商: Heatking Induction Technology (Shiyan) Corporation Shanghai Shangpin Electrical Equipment Co., ltd

供应产品

Double-station Dual Frequency Gear Ring/Shaft Quenching MachineThe machine consists of a gear ring dual frequency station and a shaft parts quenching station,Website:, which is specially applicable to gear ring quenching and camshaft parts quenching of automotive industry. The dual frequency quenching station adopts the new generation of digital high power dual frequency power supply researched and developed by Heatking Technology to realize the gear profile quenching of gear ring parts. The shaft parts quenching station has the functions of parts continuous quenching, simultaneous quenching, segmented continuous quenching, segmented simultaneous quenching and so on. The machine is suitable for the production of single piece and batch parts, and it has the advantages of reasonable structure, complete function and safe and convenient operation.ConfigurationStructure: vertical type (shaft parts quenching)+horizontal type(gear ring parts quenching)Rotary speed: shaft station: 20-150r/min, gear ring: 10-110r/min; continuously adjustableMaximum clamping length: shaft (length: 800mm, maximum load weight: 100kg), gear ring (diameter: 1000mm, weight: 200kg)Feeding speed: 0-30mm/s, continuously adjustableHigh strength weld bed, aging treatmentStainless steel(aerodynamic/manual, double/single) spring centre and stainless automatic centering clamping clawAdjustable turn ratio HKM series energy-saving quenching transformer (our patent)All water circuits are provided with electrical interface hydraulic protection, and all interfaces adopt fast-changing couplers.Rotary operation cabinet, acoustic/optical fault alarm and display Chinese alarm details.Work-piece clamping length electrical adjustmentMachine structure: welding/castingRotation control mode: Inverter/stepping motor/AC servo motorElectrical control mode: PLC/touch screen + PLC/802C/828D/840DSLWork-piece slipway adjustment: manual adjustment/ automatic adjustmentWork-piece moving motor: Speed reduction motor/ stepping motor/ AC servo motorPower supply: IGBT400kW/4-10kHz/100-150kHz

供应产品

在线联系供应商

Other supplier products

供应产品Same products

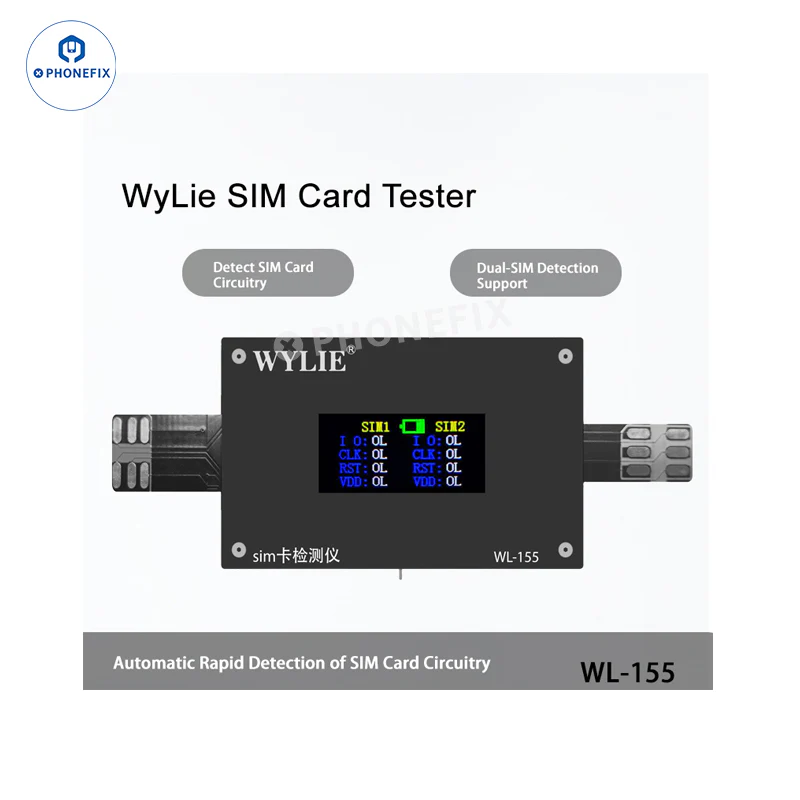

| WYLIE WL-155 SIM Card Tester for iPhone 14-17 Pro Max & Android | 卖方: China PHONEFIX Technology Co., Ltd | WYLIE WL-155 SIM卡测试仪用于检测SIM卡电路,支持iPhone 14/15/16/17 Pro Max和安卓手机的双SIM卡检测。配备LED数字显示屏,支持Type-C充电,即插... | |

| HCV1500高精度电压传感器 | 卖方: Shenzhen Hangzhi Precision Electronics Co., Ltd | HCV1500高精度电压传感器是一种能够在原边和副边完全隔离的条件下测量直流、交流、脉冲及各种不规则波形的电压传感器。它主要用于对精度要求较高的测量验证和校准领域,以及对灵敏度、稳定性、可靠性要... | |

| Xenon Test Chamber | 卖方: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | 卖方: 上海千实精密仪器 | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | 卖方: 上海千实精密仪器 | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... |