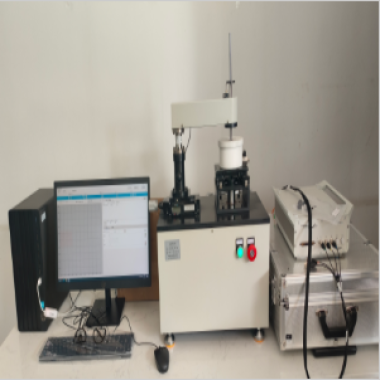

Automatic Wrinkle Recovery Tester

The main principle of the wrinkle recovery tester is to apply a predetermined pressure to the specimen under standard atmospheric conditions and to maintain the specified time. The overall structure of the instrument and the precise spiral column ensure that the loaded specimens produce a uniform deformation. After removing the sample from the instrument, re-adjust the sample under standard atmospheric conditions and allow it to recover for a certain period of time, and then compare the sample with the reference sample to assess the appearance of the sample.

The instrument consists of a base with a bracket, the base of the fixed steel plate and the top of the movable steel plate to match ,the activities of the flange with the locking pin. Equipped with four standard weights, respectively, 2000g, 1000g, 500kg, 200kg.

Application

The instrument consists of a base with a bracket, the base of the fixed steel plate and the top of the movable steel plate to match ,the activities of the flange with the locking pin. Equipped with four standard weights, respectively, 2000g, 1000g, 500kg, 200kg.

Application

The wrinkle recovery test instrument detects the recovery of the specimen after a certain period of time under a load. It is suitable for any fiber pure or blended fabric test. Besides, it can not maintain the shape of stable materials under the characteristics of the conditions, such as the material which is soft, thin and easy to bend. We can evaluate its anti-crease performance through this device.

Technical Parameters

Standard weights(2000g、1000g、500kg、200kg)

Full set 5 inch x 3 inch (5 / set)

The rating card (optional)

Standards:

AATCC 128Wrinkle recovery of fabrics: Appearance method

ISO 9867Textiles - Evaluation of the wrinkle recovery of fabrics - Appearance method

ENKA 3061

ISO 9867Textiles - Evaluation of the wrinkle recovery of fabrics - Appearance method

ENKA 3061

Accessories:

(1)First ,use the pressure sample device, three samples are tested continuously. The interval is about 1min;

(2)Fold the sample face to face. Cloth edge clip with a clip, not more than 5mm;

(3)In some cases the sample surface will be stained together. We should use a piece of paper or aluminum foil whose size is 18x14mm. Be careful not to contact the sample by hand;

(4)Place the folded sample between the two briquettes and apply the weight immediately. Turn on the chronograph and wait 60 + 2 seconds. Prepare the next sample according to 2,3,4 steps.

(5)After 5 minutes, remove the first piece of weight quickly and easily. Transfer the folded sample with the clip to the sample rack of the measuring instrument;

(6)Remove the paper or aluminum foil. Place one side of the sample in the sample holder and the other side is the free hanging. After 60 +2 seconds, Put the second and third pieces of samples into the sample folder;

(7)Adjust the instrument so that the hanging end of the sample is consistent with the vertical mark of the instrument, within 5min should be constantly adjusted (so that the hanging end of the sample is consistent with the vertical mark of the instrument,) to avoid the impact of gravity;

(8)After 5 minutes, record the recovery angle of the sample. If the sagging side is slightly curled or twisted to pass through the vertical plane of the center of the droop and the axis of the dial as a reference for the crease return angle reading;

(9)Repeat the above steps, and then do three negative fold of the sample and the zonal frontal fold and the opposite fold (a total of 12).

(2)Fold the sample face to face. Cloth edge clip with a clip, not more than 5mm;

(3)In some cases the sample surface will be stained together. We should use a piece of paper or aluminum foil whose size is 18x14mm. Be careful not to contact the sample by hand;

(4)Place the folded sample between the two briquettes and apply the weight immediately. Turn on the chronograph and wait 60 + 2 seconds. Prepare the next sample according to 2,3,4 steps.

(5)After 5 minutes, remove the first piece of weight quickly and easily. Transfer the folded sample with the clip to the sample rack of the measuring instrument;

(6)Remove the paper or aluminum foil. Place one side of the sample in the sample holder and the other side is the free hanging. After 60 +2 seconds, Put the second and third pieces of samples into the sample folder;

(7)Adjust the instrument so that the hanging end of the sample is consistent with the vertical mark of the instrument, within 5min should be constantly adjusted (so that the hanging end of the sample is consistent with the vertical mark of the instrument,) to avoid the impact of gravity;

(8)After 5 minutes, record the recovery angle of the sample. If the sagging side is slightly curled or twisted to pass through the vertical plane of the center of the droop and the axis of the dial as a reference for the crease return angle reading;

(9)Repeat the above steps, and then do three negative fold of the sample and the zonal frontal fold and the opposite fold (a total of 12).

Technical Parameters

| Items | Parameters |

| Sample size | 15cm×28cm(6×11inch) |

| Weights | 2000g,1000g,500kg,200kg Accumulate |

| Dimensions | 150×150×330mm(L×W×H) |

| Weight | 9.5kg(21lb) |

Full set 5 inch x 3 inch (5 / set)

The rating card (optional)

在线联系供应商

Other supplier products

| Photovoltaic module wire tube bending testing machine | Standard IEC 61730-2:2004: Photovoltaic (PV) Module Safety Qualification – Requirements for Testing CE Certification(Conformité Euro... | |

| protective clothing Antisynthetic blood penetration tester | It is applicable to the resistance of the protective clothing to the synthetic blood penetration under different levels of test pressure. Standa... | |

| Fabric Vertical combustion tester | Product details: fabric flame retardant performance test machine is mainly used to determine the textile flame, smoldering and carbonization tende... | |

| Cable extrusion tester | Product Introduction: The cable extrusion testing machine is suitable for the "GB/T 33594 electric vehicle charging cable" extrusion test, which au... | |

| Electrochemical Corrosion and Wear Testing Machine | Standard ASTM G119: A standard for evaluating synergistic corrosion-wear performance, particularly for biomedical implants in simulated body fluid... |

Same products

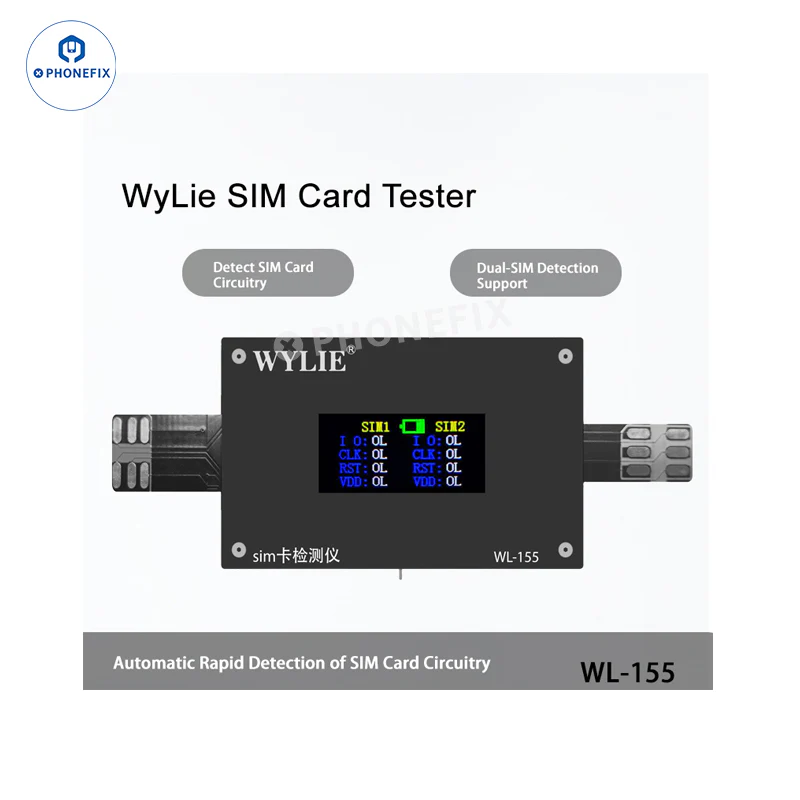

| WYLIE WL-155 SIM Card Tester for iPhone 14-17 Pro Max & Android | 卖方: China PHONEFIX Technology Co., Ltd | WYLIE WL-155 SIM卡测试仪用于检测SIM卡电路,支持iPhone 14/15/16/17 Pro Max和安卓手机的双SIM卡检测。配备LED数字显示屏,支持Type-C充电,即插... | |

| HCV1500高精度电压传感器 | 卖方: Shenzhen Hangzhi Precision Electronics Co., Ltd | HCV1500高精度电压传感器是一种能够在原边和副边完全隔离的条件下测量直流、交流、脉冲及各种不规则波形的电压传感器。它主要用于对精度要求较高的测量验证和校准领域,以及对灵敏度、稳定性、可靠性要... | |

| Xenon Test Chamber | 卖方: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | 卖方: 上海千实精密仪器 | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | 卖方: 上海千实精密仪器 | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... |