Forging Parts

Unidus forging factory has a complete production equipment and technology,Website:, a production capacity of 30,000 ton per year. Main products are petroleum machinery、I—IV type pressure vessel forging pieces for chemical industry、power station、shipping、aviation、nuclear power and all kinds of engineering machinery forgings. The shape of the products are: rotor shaft、producing all kinds of forging according to the standard of home and abroad, such as flange、wellhead equipment and valves which are used in oil production equipment 、tube forging.A broad range of forging materials GB standard carbon steel、alloy steel、heat resistance stainless steel and the ultra-low carbon stainless steel and so on. We also produced a batch of forging pieces according to the United States and the European standard material forgings. Has a mature production of A105 、 A266 、 A350 、 4130 、 4140 、 4340 、 F5 、 F11 、 F22 、 F51 、 F53 、 F91 、 F92 、 F304 ( L )、 F316 ( L )、 F321 ( L ) and other forgings according to the standard of ASME、ASTM. Mature Europe standard products are mainly: S235 、 S355 、 16Mo3 、 C422 and other carbon steel alloy steel, stainless steel forgings according to the standard of EN10025 、 EN10083 、 EN10084 、 EN10250 、 EN10283 、 EN10088 、 EN10095 and so on. With a significant feature of strong focus on researching to peer, in heat treatment section the company equip with micro-furnace, carry out experiment to new products and new materials then study its heat treatment process. At the same time, we cooperate with iron smelting company to study the Physical and Mechanical Properties of steel, reasonable mix of components. Especially for duplex stainless steel, super austenitic stainless steel, control and reasonable mix of components is very important, and it is crucial to structure control and mechanical properties. After a long-term exploration research, in the field of nuclear power and aviation, there are special requirements for those special material, we have a lot of valuable experience in the process of forging and heat treatment.In the forging process, after many years of trial practice, the company has formed a complete set of technical process from the raw materials, heating, forging to heat treatment. Especially the high-temperature alloy steel forging, our forging parts NiCr20TiAl, the content of Ni up to 65%, and its forging is very difficult. Now, the high-temperature alloy product forged by us has successfully taken place of imported products.

Other supplier products

|

|

|

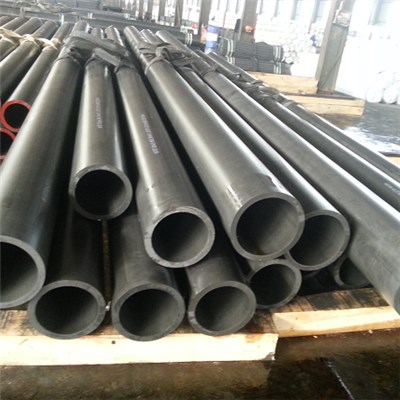

Honed Tube,Website:, with standard DIN2391,EN10305-1/2,GB/8713,we manufacture from OD40mm to 800mm and length 14meter max. Our yearly capacity is 1... |

|

|

|

U-Bend TubeU-bend tubes are widely used in heat-exchanger systems. Heat-exchanger equipment on the basis of seamless stainless U-tubes is essential... |

|

|

|

Super Austenitic Stainless Steel PipeWhen cr-ni austenitic stainless steel pitting resistance equivalent value (PREN = 3.3 [Mo] [Cr] + + 16 [N]) & ... |

|

|

|

Our company is successfully ranked as the Manufacturer,Website:, Exporter and Supplier of Hydraulic Cylinder Pipes from China. The Hydraulic Cylind... |

|

|

|

Unidus Group also manufacture and supplied special shaped steel tubes which satisfied the customer’s demand from different business line such as Ae... |

供应产品

Same products