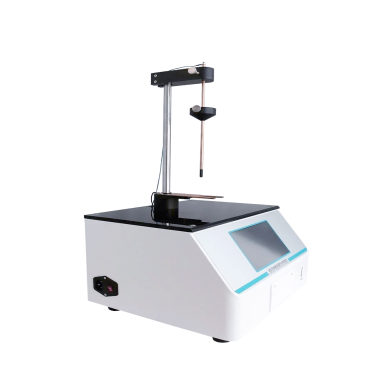

Aluminum Ointment Tube Toughness Tester

The ductility tester for aluminum tubes is a device specifically used to detect the ductility indicators of packaging materials such as aluminum soft tubes. The following is a detailed description of its main uses, compliance standards, and technical parameters:

Compliance Standards

The design and manufacture of the ductility tester for aluminum tubes usually comply with a series of national and international standards to ensure the accuracy and reliability of test results. Among them, common standards include YBB00162002 - 2015 Aluminum Pharmaceutical Soft Tubes, etc. These standards specify in detail the test methods for the ductility of aluminum tubes, specimen preparation, test conditions, etc., providing a unified standard for the use of the tester.

Main Uses

The main purpose of the ductility tester for aluminum tubes is to evaluate the deformation and recovery ability, that is, the ductility, of packaging materials such as aluminum soft tubes under external forces.

Through testing, we can understand the performance of aluminum tubes when subjected to external forces such as extrusion and bending during transportation, storage, and use, thereby ensuring the safety and integrity of products.

This is particularly important for industries such as medicine, cosmetics, glue, and toothpaste. As the main packaging material for products in these industries, the ductility of aluminum soft tubes directly affects the product's user experience and market competitiveness.

Technical Parameters

- Measurement Range: Usually applicable to aluminum soft tubes with an aluminum tube diameter between 10 and 45mm (some devices also cover the range of 8 - 45mm) and the tube length within a certain range. This range covers most common aluminum tube specifications, giving the tester wide applicability.

- Gate Plate Weight: The gate plate is a key component in the tester for applying pressure, and its weight is usually precisely controlled within the range of 70g±1g to ensure the consistency and accuracy of testing.

- Testing Accuracy: Modern ductility testers for aluminum tubes are usually equipped with a high - precision measurement system, which can accurately quantify the degree of deformation of aluminum tubes under external forces. The testing accuracy is relatively high. For example, the current measurement accuracy can reach ±0.1mA (the specific accuracy may vary depending on the device).

- Automation Level: Some advanced ductility testers for aluminum tubes adopt automated and intelligent technologies, making the testing process more convenient and efficient. One - click operation, automatic timing, and data recording functions greatly reduce the burden of operators and improve the accuracy and traceability of test results.

- Appearance Dimensions and Weight: The appearance dimensions and weight of the tester may vary depending on the model and brand, but it is usually designed to be compact and portable. This enables the tester to be used in different production sites and laboratories, improving the flexibility and convenience of testing.

- Working Environment: To ensure the normal operation of the tester and the accuracy of test results, it usually needs to be used in a certain working environment. For example, the working temperature is between 23°C±2°C, and the relative humidity does not exceed 80% (without condensation). These working environment requirements help maintain the stability and reliability of the equipment.

在线联系供应商

Other supplier products

| Flex Durability Tester ASTM | The rubbing resistance tester is a device specifically used to detect the rubbing resistance performance of materials. The following is a detailed ... | |

| Fuel Contamination Test Dust | Product Introduction: Particle Technology UK offers a full range of materials used in fuel contamination tests, which are used to test the reliabi... | |

| AT1000 Abrasion Resistance Tester | Device description The at1000 wear tester has been used around the world since 1970 and is ideal for comparison and quality control of platelet-sh... | |

| Rubber non-rotor vulcanization Tester丨 Rubber Testing Instruments | Product Introduction: Non-rotor vulcanizer is a rubber processing industry control rubber material quality, rapid inspection and rubber basic rese... | |

| Snap Button Tester | Button Snap Pull Tester | Standard ASTM D7142-2/F963: Standard Consumer Safety Specification for Toy Safety CFR 1500: Consumer Product Safety Commission (CPSC) Hazardous S... |

Same products

| Bottle Wall and Bottom Thickness Tester | 卖方: Standard Group (Hong Kong) Limited | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pha... | |

| Pinhole Tester / Pinhole Testing Equipment | 卖方: Standard Group (Hong Kong) Limited | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in ... | |

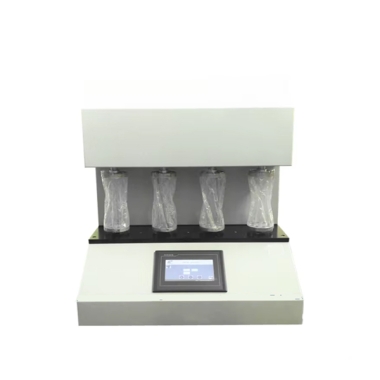

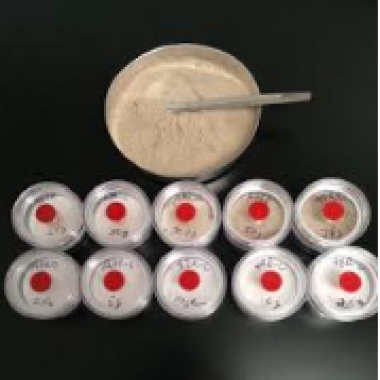

| Cork Puncture and Chip Detection Instrument | 卖方: Standard Group (Hong Kong) Limited | The rubber stopper puncture debris detector is a device specifically used to detect the number of... | |

| Aluminum Ointment Tube Toughness Tester | 卖方: Standard Group (Hong Kong) Limited | The ductility tester for aluminum tubes is a device specifically used to detect the ductility ind... | |

| Vacuum leak tester / Vacuum leak instrument | 卖方: Standard Group (Hong Kong) Limited | Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bott... |