ASTM F67 GR2 Titanium Capillary Tube For Medical Use

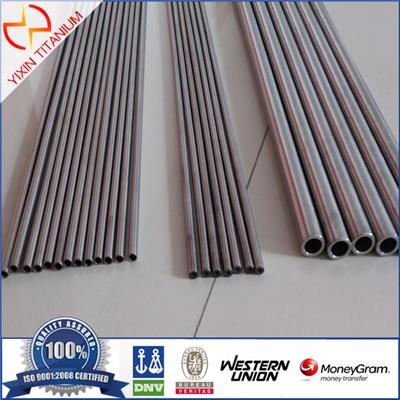

1.Product description:Item nameASTM F67 GR2 Titanium Capillary tube for Medical useStandardASTM F67GradeGR2DimensionOD3mm*Thickness0.3mm* L1000mmTechniqueSeamlessConditionAnnealed(M)FeaturesLow density, High specific strength, Excellent corrosive resistance, Rustless, Good thermal stability, Good thermal conductivity, Biological features, Plasticity, etc.2. Titanium Application in Medical IndustryTitanium application in medical industry holds following superiority:●Corrosion resistance●Biocompatibility●Excellent mechanical and fatigue properties●Thoughness●Low modulus of elasticity●Good wear resistance in assembled condition●Acceptable priceTitanium and its alloy for medical (surgical implants) use now have several type as below:●commercial purity titanium●Ti-6Al-4V and Ti-6Al-4V ELI alloy●Ti-6Al-7Nb alloy●Novel titanium alloys●Ti-Ni alloyMaterial grade in surgical implant:●Pure titanium(ASTN F67):Grade 1,2,3,4●Ti-6Al-4V ELI(Wrought: ASTM F136 and forged: ASTM F620): α+β type●Ti-6Al-4V (Casting: F1108): α+β type●Ti-6Al-7Nb(ASTM F1295) : α+β type (Switzerland)●Ti-5Al-2.5Fe(ISO/DIS 5832-10): β rich α+β type (Germany)●Ti-5Al-3Mo-4Zr: α+β type (Japan)●Ti-15Sn-4Nb-2Ta-0.2Pd: α+β type (Japan)●Ti-15Zr-4Nb-2Ta-0.2Pd: α+β type (Japan)●Ti-13Nb-13Zr: near β type(USA), low modulus●Ti-12Mo-6Zr-2Fe: β type(USA), low modulus●Ti-15Mo: β type(USA), low modulus●Ti-16Nb-10Hf: β type(USA), low modulus●Ti-15Mo-5Zr-3Al: β type(Japan), low modulus●Ti-15Mo-5Zr-3Nb: 12.β type(USA), low modulus●Ti-35.3Nb-5.1Ta-7.1Zr: β type(USA), low modulus●Ti-29Nb-13Ta-4.6Zr: β type(Japan), low modulus 3. Titanium in Orthopedic and Dental implant OrthopedicThe

1950's saw the first use of titanium in orthopedic applications and now

titanium is the standard material of choice for orthopedic devices such

as hip joints, bone screws, knee joints, spinal fusion cages, shoulder

and elbow joints, and bone plates.Titanium

has been selected as a metal of choice in the orthopedic segment of the

market because it is inert in the human body, it is resistant to attack

body fluids, has proven to be compatible with bone density, is strong

and has a low modulus, hence making it an excellent material of choice

in the orthopedic arena.The

human body readily accepts titanium as it has proven to be more

biocompatible than stainless steel or cobalt chrome. In addition,

titanium has a higher fatigue strength than many other metals.

Compatibility with MRI (Magnetic Resonance Imaging) and CT (Computed

Technology) also contribute to the selection of titanium as the material

of choice in orthopedic applications. Dental ImplantsA dental implant is an artificial tooth root used in dentistry to support restorations that resemble a tooth or group of teeth.Virtually

all dental implants placed today are root-form endosseous implants. In

other words, virtually all dental implants placed in the 21st century

appear similar to an actual tooth root (and thus possess a "root-form")

and are placed within the bone (end- being the Greek prefix for "in"

and osseous referring to "bone").Prior

to the advent of root-form endosseous implants, most implants were

either blade endosseous implants, in that the shape of the metal piece

placed within the bone resembled a flat blade, or subperiosteal

implants, in which a framework was constructed to lie upon and was

attached with screws to the exposed bone of the jaws.Dental implants can be used to support a number of dental prostheses, including crowns, implant-supported bridges or dentures.Titanium

was actually first used in dentistry in the 1940's. Today titanium is

routinely utilized in the dental industry for implants and orthodontic

braces.The

titanium implant acts as an artificial root for a tooth and is securely

implanted into bone to provide a solid base for a tooth. Compared to

traditional orthodontic braces made of steel, titanium braces are

stronger, lighter, and more compatible to body fluids and bone density.Titanium

has been selected a metal of choice in the dental market due to its

total resistance to attack by body fluids, high strength and low

modulus. OthersAlthough

orthopedic and dental applications comprise a significant portion of

titanium's utilization in the medical venue, there are other medical

applications for titanium.Some

of these application include surgical staples, urethral stints,

wheelchairs, pacemaker cases, and heart valves. Titanium is also the

metal of choice for surgical instruments, dental drills, marker bands,

needles and surgical devices.Titanium

has been selected as a material of choice in the medical market due to

its total resistance to attack by body fluids, high strength, low

modulus, and fracture toughness.4. Production Scope:Titanium

tubes have the feature of light weight, high strength and superior

mechanical properties. Titanium tubes are widely used in heat-exchange

equipment, such as tube type heat-exchanger,coiled type

heat-exchanger,coil heat-exchanger, condensator,evaporator and

transmission pipeline. Many nuclear power industry ues titanium tubes as

the unit standard tubes.ProductsSeamless tube/pipeWelded Tube/PipeMaterialGr1, Gr2, Gr3, GR5, Gr7, Gr9, Gr11, Gr12GR1,GR2,GR5produce MethodRollingForgingWeldingOD3~108MM108~400mm6mm~32mmThinkness0.3~12mm10~50mm0.5mm~1.2mmLengthMax 9000mmas per client requirementsStandardASTM B338,ASTM B337, ASTM B861, ASTM F67, ASTM F136ASTM B338,ASTM B337, ASTM B862 ConditionAnnealed(M)Annealed(M)InspectionUltrasonic testing, Hydrostatic testing, Flattening testing, visual surface inspection, Dimensional inspection, tensile properties inspection and Chemical elements analysis.FeaturesLight weight, excellent corrosion resistivity, strongly heat-resistance, high strength.ApplicationGeneral service industries (petroleum, food, chemical, paper, fertilizer, fabric, aviation and nuclear)Fluid, gas and oil transportPressure and heat transmissionConstruction and ornamentBoiler heat exchangersmotorbycle and bikeMedical Use5. Titanium Application:★.Oil drilling equipments★.Industrial precision instruments standard parts★.Medical instruments standard parts★.Aerocraft engine★.Machinery,electroplating equipment★.Titanium wind leaf in power industryTitanium

have a wide use in medical, oil&gas industry, deepwater oil and

shipbuilding industries, power industry, metallurgical industry, light

industry, chemical industry.6. Product Testing●According

to globally recognized standards, such as ASTM, AMS, ASMEand provide

third-party inspection reports, DNVaccredited ISO 9001: 2008 quality

management system.●100% titanium sponge to produce titanium ingot

and 3 times melting to ensure the uniformity of chemical composition.

For chemical composition inspection , not only inspect the titanium

ingot, but also the semi finished products and finished products, just

to ensure 100% qualified products before shipping.●Mechanical property testing making sure all titanium products can satisfy mechanical features before delivery.●Strict

inspection when producing and finished products.Visual inspection to

check surface quality, ensuring without flaw, black dot and any other

defects.●Ultrasonic Flaw Detection make sure there are no defect inside.●Chemical Composition detection make sure all chemical component can meet your demands.●Yield strength,tensile strength ,elongation percentage reduction of area,Impact bending test,microstructure tests, bending strength test etc.● Hardness testing, Penetrant testing, Radiographic testing etc. as per your requirements.Yixin can promise all products have high traceability from ingot to finished products.7. Packing and ShippingPE foam + wooden case, or as you requested to ensure safety transporation.We can ship goods by sea,by air,by door to door international express.(DHL,Fedex,UPS,TNT,EMS,etc.)★Why us?★ Our advantages 1.High quality 2.Reasonable price 3.Strict quality control 4.On time deliveryWe will offer you 1.In-time response by E-mail, Tele or Fax etc., 2.In-time communication on technical points 3.In-time sending pictures and status of production process 4.In-time testing and sample delivery 5.In-time mass production delivery.#

20 years of manufacturing experience and giant technology leaps enables

our products extraordinary quality which can be used in extreme

environment;# 10 years of exporting experience makes us sophisticated and considerate;#

9 years of successful collaboration with Global Top 25 companies

witnesses our stable quality and devotion on OHSE management system. Want

to enjoy your time with family instead of tackle problems caused by

suppliers? Let us handle your order, because we know how to make things

easy and perfect for you.

Other supplier products

|

|

|

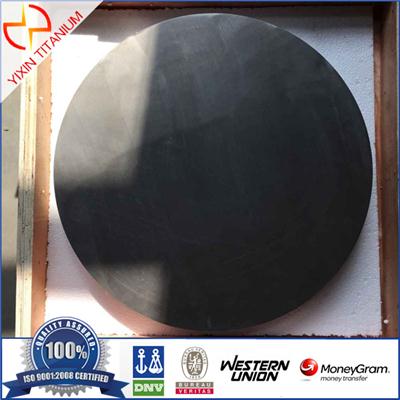

1.Product description:Item nameGR5 Titanium Forged Ring with Low Price for Industry UsingStandardASTM B381SizeOD331*ID271*T88GradeGr5Manufacturing ... |

|

|

|

Titanium Cadding Sheet,Titanium Plate And Wire And Bar |

|

|

|

Unstandard Titanium Fasteners,Other Shape Fastener |

|

|

|

1. Product DescriptionItem NameTitanium Bar/RodGradeGR5StandardASTM F136DiameterDia 12.7mmLength3000mmApplicationMedicalShapeRoundColorSilverTechni... |

|

|

|

Item NameColored Ti Gr5 SpringClassN/AGradeGR2、GR5、StandardN/AWire Dia3-30mmSurfacePolishing Length 100-1000mmTotal CoilAs per drawingApplication... |

供应产品

Same products