Titanium carbide hard bar - a substitute for die steel

Hard alloy titanium carbide round rods can be tailored to achieve specific performance characteristics by adjusting the titanium carbide content (typically 70%–90%) and the binder proportion. A higher titanium carbide content enhances wear resistance, making the material suitable for rough machining applications, while an increased binder proportion improves toughness, rendering it more appropriate for precision machining. With a density of only 6.5 g/cm³, these rods are approximately 20% lighter than tungsten carbide counterparts of comparable dimensions, which makes them ideal for lightweight tooling solutions. In the 3C electronics industry, they are widely employed in the machining of high-precision components such as mobile frames and laptop housings, ensuring scratch-free surfaces and minimal dimensional deviations. The oxidation resistance of hard alloy titanium carbide round rods can withstand temperatures up to 800 °C, reducing oxidative wear in high-temperature cutting environments and enabling efficient processing of challenging materials like high-temperature alloys. When subjected to mirror surface finishing, the coefficient of friction can be reduced to as low as 0.1, significantly decreasing frictional resistance during machining and contributing to lower energy consumption. In textile machinery, these rods are commonly used to fabricate wear-resistant guide rods, preventing yarn damage during high-speed operation and enhancing overall textile quality.

Other supplier products

|

|

Titanium carbide guide wheel - hard alloy transmission |

Hard alloy titanium carbide guide wheels have excellent impact resistance. When the wire is suddenly tensioned or broken, they are not prone to cra... |

|

|

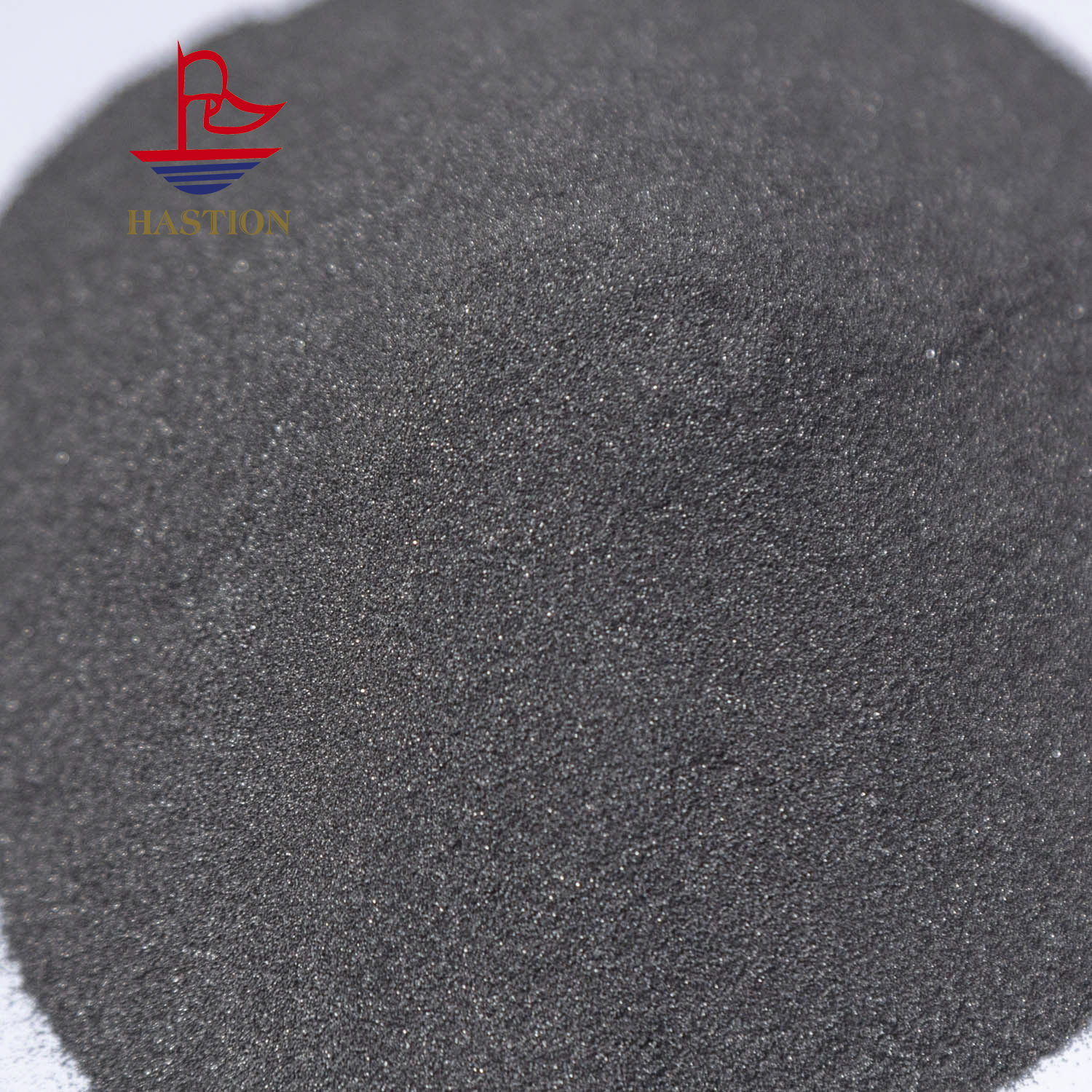

Sintered reactive high titanium carbide powder |

Titanium Carbide powder is a grey-black high hardness ultra-fine powder with the chemical formula of TiC, which has both metal and ceramic properti... |

|

|

Aerospace grade titanium carbide powder |

TiC titanium carbide powder materials are widely used in machining, electronic information, metallurgy and minerals, aerospace and fusion reactor... |

|

|

Chromium carbide powder for metallurgical wear-resistant parts |

This chromium carbide powder is black in color, with a particle size of 5-25μm, a purity of over 99%, and extremely low impurity content. The pa... |

|

|

Titanium carbide alloy rods are suitable for metal stamping |

Compared with traditional high-speed steel, hard alloy titanium carbide round bars enable a 3 to 5 times increase in cutting speed, significantly r... |

供应产品

Same products