Forged Clevis

Product: Forged steel clevis

Application: hydraulic cylinder

Place of origin: Hebei, China (Mainland)

Material: C45, 20, ASTM A216 70-36 grade WCB

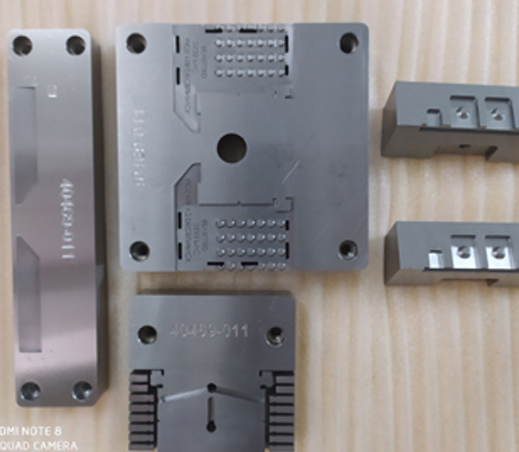

Process: die mold forged, forging + CNC machining,

Surface treatment: anti-rust oil or painting

Surface roughness: 12.5Ra

Weight: 0.5-50kg

Sample lead-time: 3-8 weeks

Heat treatment: normalizing, quenching, tempering and annealing

Forged clevis is a kind of mechanical device designed as a convenient method of connecting hanger rods to pipe lugs, angles, etc. As a structural attachment, hydraulic cylinder clevis is most commonly used in conjunction with Fig. 935 welding lug. Right-Hand Threads (Fig. 38) or Left-Hand Threads (Fig. 38L).

Forged Clevis

Product Description

Hydraulic Cylinder Clevis Description

Customized drawings are accepted.

Standards: ASTM, AISI, ANSI, AWS, ASME, AB, SAE, API, BS, CAS, JIS and DIN

Packing: seaworthy packing or as per clients' requirements

Competitive Advantages of Hydraulic Cylinder Clevis:

The hydraulic cylinder clevis used on different type of cylinders, strong and durable.

The precision forging process of hydraulic cylinder clevis can guarantee the material without defect inside the parts.

We can provide machined hydraulic cylinder clevis according to customer’s drawings.

Forging is a process method that uses custom forgingmachinery to exert pressure on metal blanks, causing them to create plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. By forging can eliminate the metal in the smelting process of the casting state loose and other defects, optimize the microstructure, and because of the preservation of complete metal streamlined, forging mechanical properties are generally better than the same material castings

As one of the leading custom forged partsmanufacturers, JC Forging provides custom forged parts of various shapes, such as forged hydraulic cylinder bottoms, forged hydraulic cylinder end caps, forged hydraulic cylinder heads, forged hydraulic cylinder clevis, forged trunnions, etc. Forging is a manufacturing process involving the shaping of metal through hammering, pressing, or rolling.

在线联系供应商

Other supplier products

| Forged Clevis | Product: Forged clevis Application: hydraulic cylinder Place of origin: Hebei, China (Mainland) Material: C45, 20, ASTM A216 70-36 grade WCB Pr... | |

| Medium Excavator Series Cylinders | Brief Introduction: This type of cylinder is mainly used for medium excavators, including stick cylinders, boom cylinders, and bucket cylinders. U... | |

| Hydraulic Cylinder | Hydraulic cylinder is an actuator that converts hydraulic energy into mechanical energy and performs linear reciprocating motion (or oscillating mo... | |

| Forged Trunnion | Product: forged trunnion ak Application: hydraulic cylinder, truck Place of origin: Hebei, China (Mainland) Material: C45, 20, ASTM A216 7... | |

| BM2 Hydraulic Spool Valve Motor | Brief Introductionof hydraulic motor spool valve: BM2 motor is a spool valve type motor. Characteristic Features: 1, Spool valve motoradapt ... |

Same products

| Cast iron service | 卖方: 山西海洛斯铸锻件有限公司 | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | 卖方: 山西海洛斯铸锻件有限公司 | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | 卖方: 新航金属制品有限公司 | 铬镍铁合金定向铸造服务:高性能应用的高精度 因科镍合金以其卓越的强度和耐高温性而闻名,是需要能够在极端条件下运行的部件的行业中不可或缺的材料。航空航天、发电和石化等行业要求材料不仅能承受高温,而... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | 卖方: 新航金属制品有限公司 | 因科镍合金粉末冶金涡轮盘服务:高性能部件的先进制造 铬镍铁合金粉末冶金 (PM) 涡轮盘制造对于为航空航天、发电以及石油和天然气等需要最高可靠性和强度的行业生产高性能部件至关重要。涡轮盘是喷气发... | |

| CMSX Series Single Crystal Casting Service | 卖方: 新航金属制品有限公司 | CMSX系列单晶铸造服务简介 CMSX 系列是一系列先进的单晶高温合金材料,专为高温应用而设计,特别是在航空航天和发电行业。这些合金以其在极端条件下的卓越性能而闻名,例如燃气轮机、喷气发动机和其... |