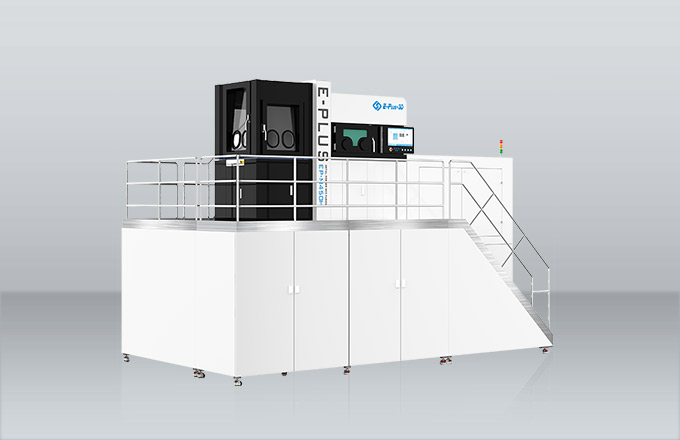

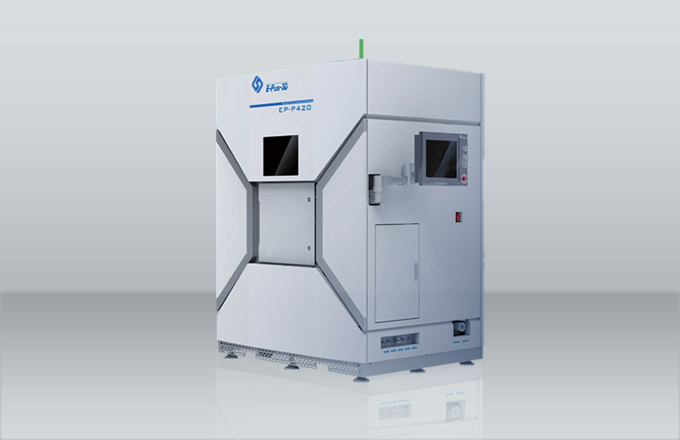

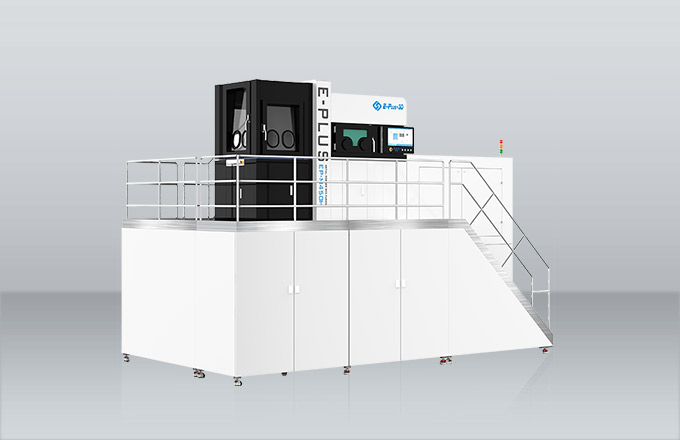

Additive Manufacturing Machine

Renowned as one of the preeminent 3D printing machine manufacturersin China, Eplus3D specializes in a diverse range of industrial 3D printing machines. We offers industrial 3D printing systems that can be flexibly integrated into existing production environments, equipped with a wide range of different building volumes, powerful multi-laser options, and advanced in-build monitoring and scanning system. Eplus3D's industrial 3d printing equipment manufacturershigh-quality parts with excellent mechanical performance and accuracy.

What is the difference between CNC and additive manufacturing?

The main difference between 3D printing and CNC is that they work differently. 3D printing is an additive technology, while CNC is a subtractive technology. As we all know, 3D printing is easier to use than CNC machining. When the file is ready, you only need to select the part orientation, fill and support as needed. Then start to print. There is no need for a supervisor to supervise the whole process of printing. However, CNC is a labor-intensive process. It requires both skilled operators and different tools. It also requires complicated post-processing.

Why do we use additive manufacturing?

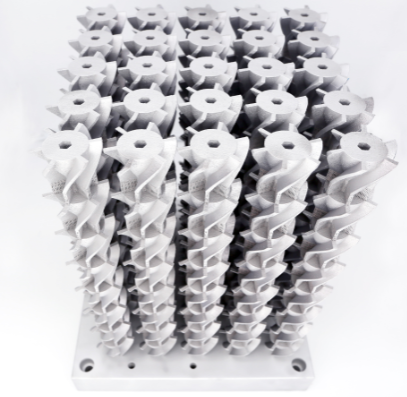

Additive manufacturing has the ability to reduce the time to produce complex prototypes. By applying additive manufacturing, products can be put into the market quickly by avoiding wasting valuable time waiting for changing tools or mold. For any changes or adjustments to the design, it can be made to the CAD file and programmed into the 3D printer in simple ways. 3D printers can also lower the time needed to manufacture fully functional products for use in operations. The process of additive manufacturing is additive, making it possible to manufacture products in a single step, without the need to produce different parts to be assembled later, thereby reducing production time.

Further, the additive approach can help in producing more rugged and sturdy equipment. This gives it a competitive edge over traditional manufacturing processes and also improves material use by reducing waste. Traditional manufacturing results in lots of waste that may not be correctly recycled, on the contrary, the only material that is consumed via additive manufacturing is the actual material used for the end product.

For more information about metal 3d printer chinaand additive manufacturing machine price, please feel free to contact us!

在线联系供应商

Other supplier products

| SLS 3D Printer | Eplus3D Polymer 3D SLSAluminium Printing Machines and Materials For Your Needs Eplus3D SLS polymer 3D printers are flexible machines for industri... | |

| Eplus3D Metal Additive Manufacturing | Machines & Materials For Your Metal 3D Printing Demands Eplus3D metal printers are a lab from entry-level models to multi-layer machines for a... | |

| EP-M300 Metal 3D Printer | EP-M300 is a marvelous industrial metal 3D printerthat makes the production of reliable and high-quality large metallic parts viable on an industri... | |

| EP-A650 Resin 3D Printer | EP-A650 3DMetal PrinterStereo Lithography is developed by Eplus3D, which is professional in 3D EP printingtechnology. The system is user-friendly w... | |

| Additive Manufacturing Photosensitive Resin Material | Eplus3D considers materials to be part of its core competency, Eplus3D's experienced material department has independently developed a portfolio of... |

Same products

| The ideal solution for fine circuit repairs | 卖方: 深圳市维客修科技有限公司 | 描述 G-LON 0.005MM非漆包铜线纯铜跳线适用于电子/手机/iPhone主板指纹BGA CPU IC维修。100M非漆包铜线适用于各种电子产品电路板的精密维修。 特点: 1.极细规格:... | |

| Additive Manufacturing Machine | 卖方: Eplus3D | Renowned as one of the preeminent 3D printing machine manufacturersin China, Eplus3D specializes ... | |

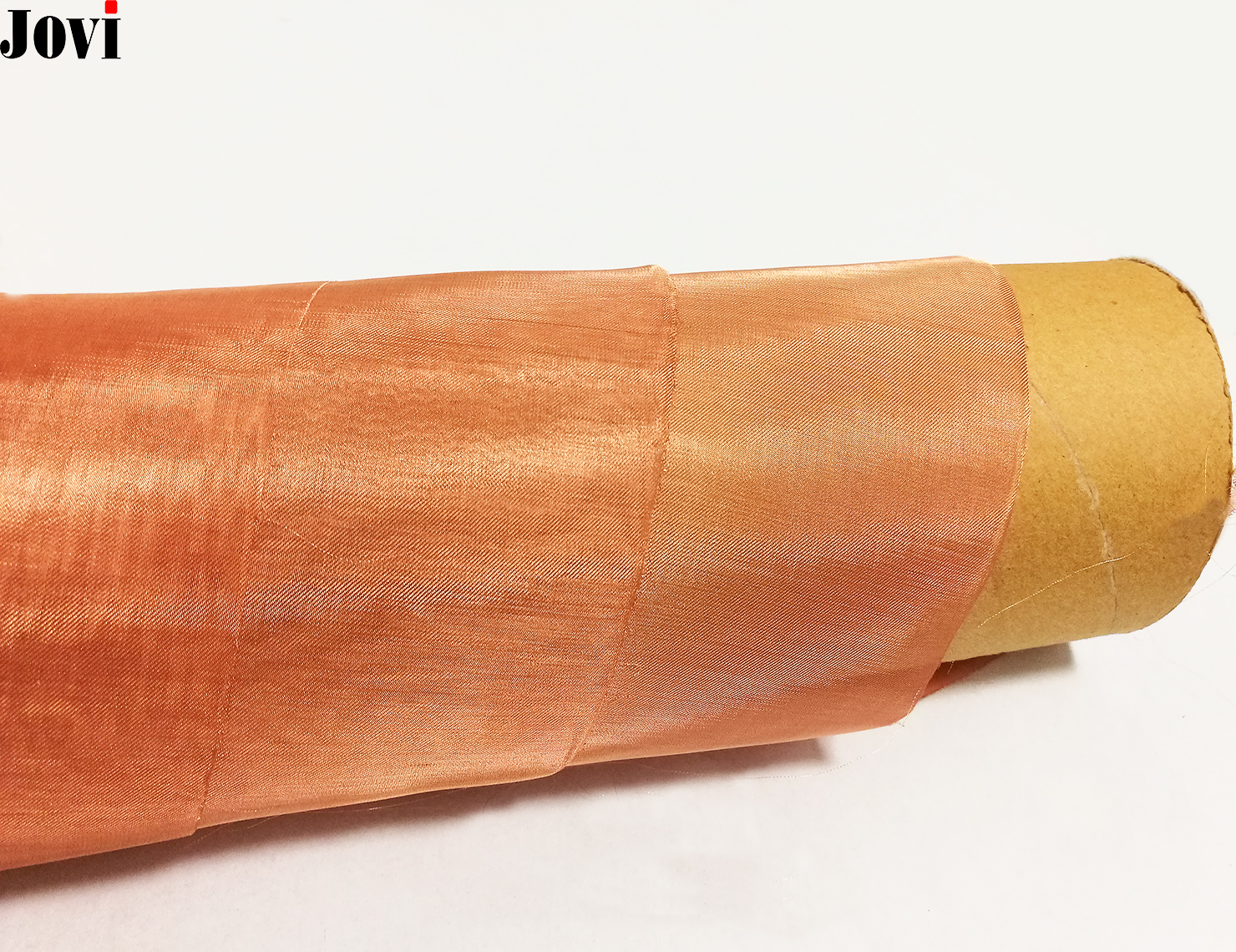

| 铜网 | 卖方: 北京中景恒泰科技有限公司 | We can offer customized size copper mesh. Different size will have different effects. Actually, 1... | |

| Copper wire 99.95% | 卖方: Handan Ouguan Metal Material Import and Export Trading Co., Ltd. | Copper Cathode Gross weight of each container: 22.20mts approx. Copper wire 99.95% We are Copper ... | |

| Millberry铜线废料99.99% | 卖方: CME组 | Millberry铜线废料99.99%铜线废料 1级废铜未与规格混合C11000电解韧性浆料铜(ETP)含量99.9%。 铜%:99.9% 元素... 0.005 ...(%) 铜...99.9... |